LED (light-emitting diode) lawn lamp using support composite member as mounting interface

A technology of LED lawn light and installation interface, which is applied to the parts of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of difficult maintenance, many product specifications, inconvenient use, etc. Simple and smooth structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

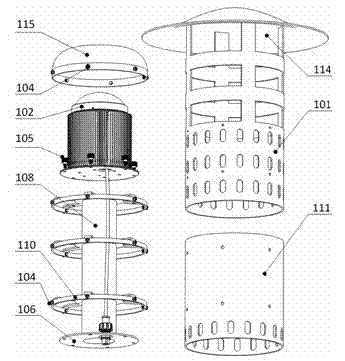

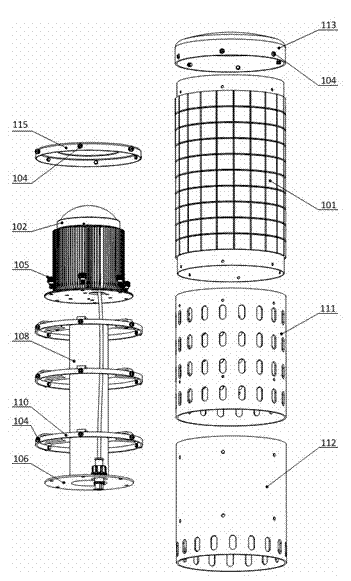

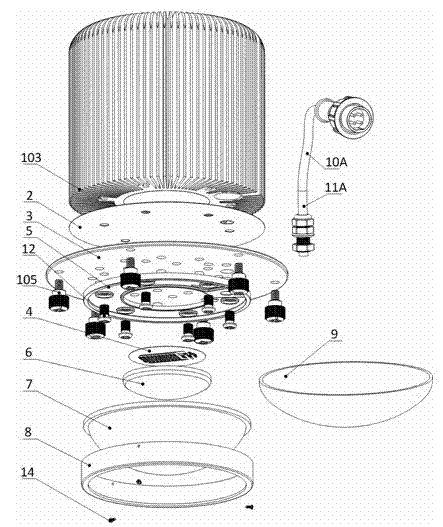

[0074] Example 1. LED lawn lamps that use a combination of mounting interface brackets, such as figure 1 , Figure 25 with Figure 26 As shown, it includes the installation interface bracket combination member. The installation interface bracket combination member is provided with a waterproof, dustproof function and LED bulb 102 with its own radiator. The installation interface bracket combination member is provided with metal stamping or plastic die-casting. Lampshade assembly; the installation interface bracket combination member includes connected pipe brackets 108 cut into sections from standard pipes, lamp fixing flanges 106, lampshades and bulb fixing brackets 110; lampshades and bulb fixing brackets 110 are equipped with The installation interface of the LED bulb 102, the pipe bracket 108 is connected to the lamp fixing flange 106 and the lampshade and the bulb fixing bracket 110; The installation interface includes a surface and a connection hole that are in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com