LED (Light-Emitting Diode) streetlamp utilizing extrusion type mounting interface bracket structure

A technology for LED street lamps and installation interfaces, which is applied to components of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc. Facilitate standardized mass production, high versatility and interchangeability, and improve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

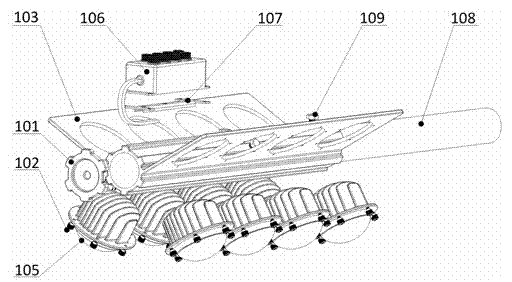

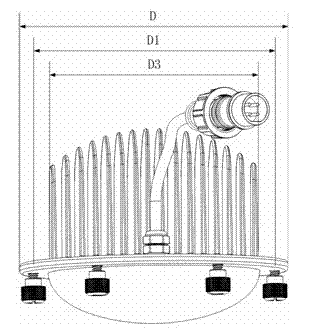

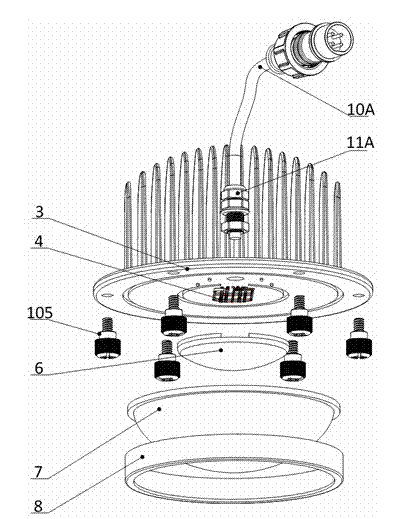

[0056] Example. An LED street lamp adopting an extruded mounting interface bracket structure, such as figure 1 , Figure 14 and Figure 15 As shown, it includes an extrusion-type installation interface bracket 103, and the extrusion-type installation interface bracket 103 is fixed on the light pole 108; the extrusion-type installation interface bracket 103 includes a light pole fixing sleeve, and both sides of the light pole fixing sleeve are provided with bracket panels , the bracket panel is provided with an installation interface for installing the LED light bulb 102; the LED light bulb 102 with waterproof and dustproof functions and a heat sink is installed on the installation interface. The LED street lamp adopting the extruded mounting interface bracket structure also includes a wire harness connector 106, which is arranged on the lamp pole fixing sleeve, and the wire harness connector 106 is used for connecting the LED bulb 102 to a power supply and a control cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com