Interferometric sensor based on microstructured optical fiber selectively filled with functional materials

A technology of microstructured optical fibers and functional materials, which is applied in the transmission of sensing components, cladding optical fibers, optical waveguides and light guides using optical devices to achieve the effect of flexible implementation and high sensing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment: The description is as follows in conjunction with the accompanying drawings.

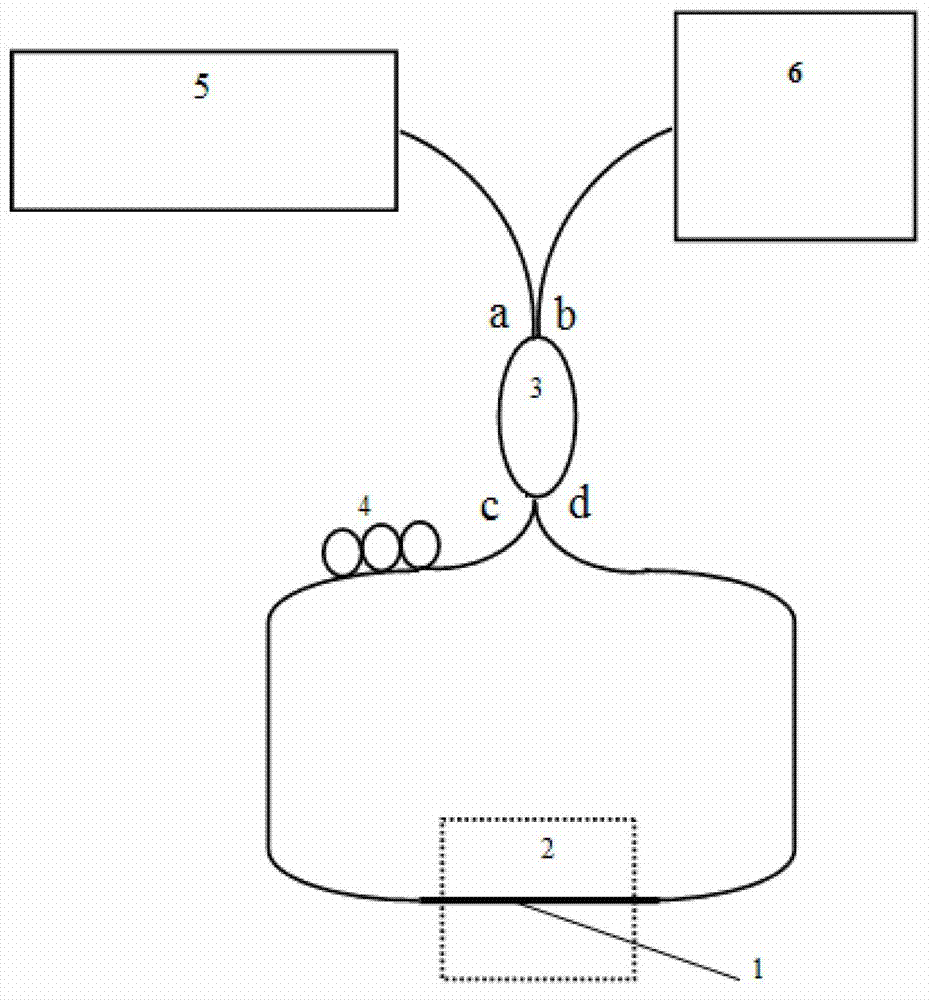

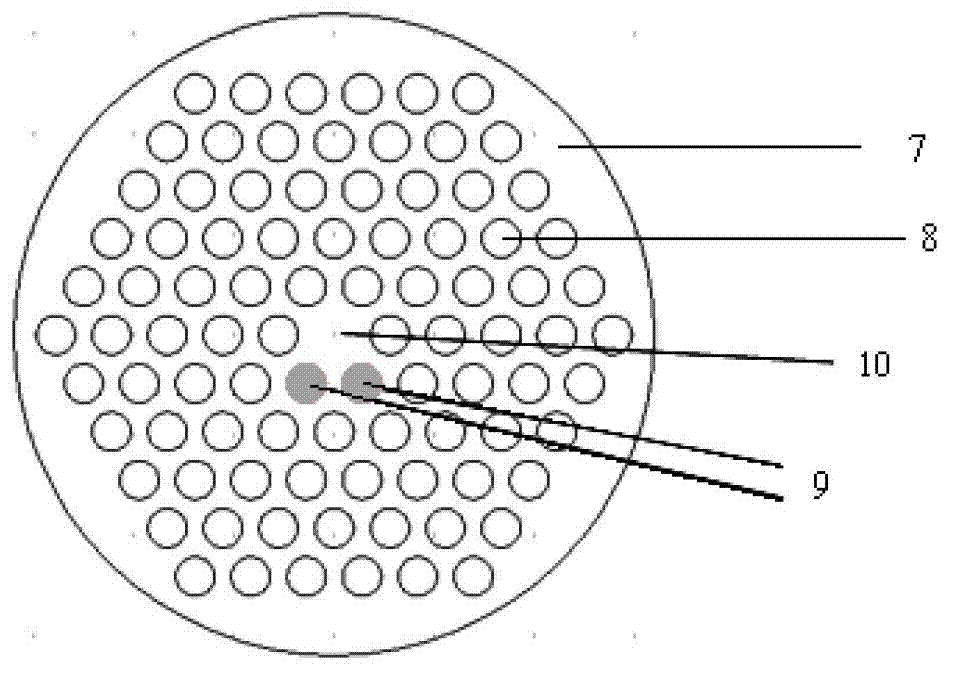

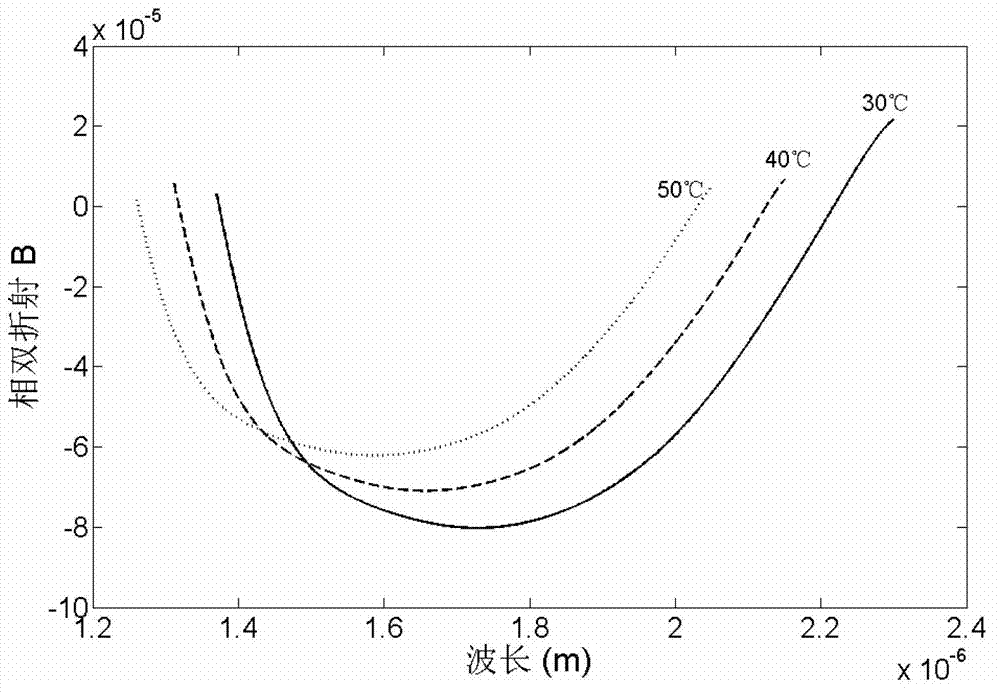

[0030] like figure 1 The shown interferometric sensor based on a functional material selectively filled microstructured optical fiber, a birefringent microstructured optical fiber selectively filled with functional materials (1), an external sensing parameter loading device (2), a four-port optical directional coupler ( 3), the polarization controller (4) is composed; the birefringent microstructure optical fiber selectively filled with functional materials is the sensing head, which is located in the sensing parameter loading device. The fourth port d is connected with one end of the polarization controller (4), and the other end of the polarization controller is connected with the third port c of the four-port optical directional coupler; the first port a of the four-port optical directional coupler It is connected with the broadband light source (5) (the spectrum covers the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com