Muffling structure

A sound-absorbing material and film technology, which is applied in the direction of sound-generating devices, layered products, instruments, etc., can solve the problems of increasing material thickness and dosage, increasing material, and reducing the cost performance of sound-absorbing materials, so as to achieve good sound-absorbing effect, avoid strong reflection, and The effect of the noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

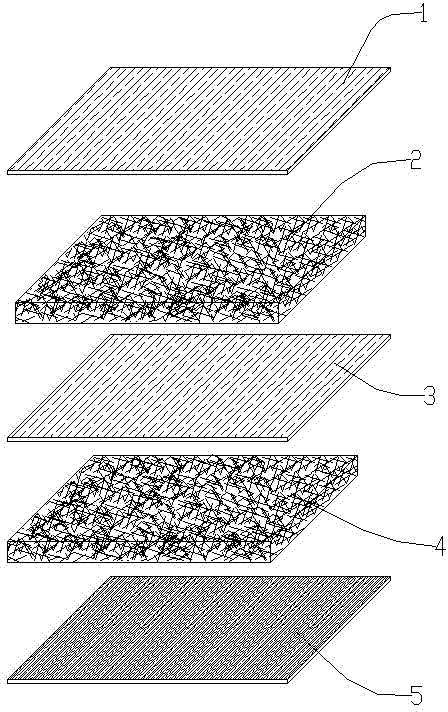

[0014] A sound-absorbing structure such as figure 1 , comprising a first fiber material layer 2 and a second fiber material layer 4 made of fiber material, a plastic film 3 made of PP is arranged between the first fiber material layer and the second fiber material layer, the first fiber material layer Films 1, 5 made of PE and PET materials are arranged on the outside of the second fiber material layer, respectively. The surface of each layer of film is soft, uneven in thickness, and the surface is undulating and uneven. The membrane resonance structure formed by the thin film between the two fiber material layers and the two outer thin films forms absorption peaks for noise in multiple different frequency bands; thereby achieving excellent sound absorption and noise reduction effects. The distance between the films can be different, that is, the thickness of the fiber material layer is different. Through the setting of different distances, the difference in the frequency ban...

Embodiment 2

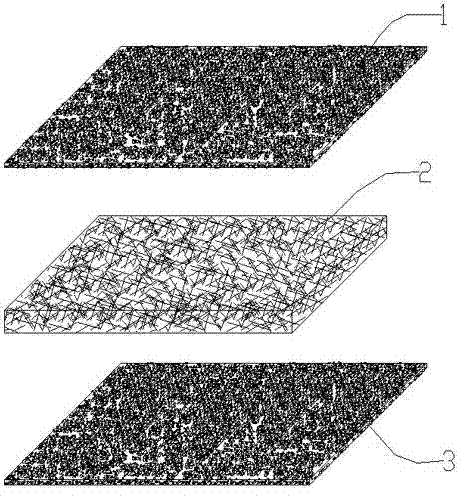

[0019] A sound-absorbing structure such as figure 2 , including a fiber material layer 2, films 1 and 3 are arranged on both sides of the fiber material layer, and the film is a soft film processed from one of PP, PE, PET, EVA materials, or more than one of them A soft film made of a mixture of two materials. The surface of the film is soft and undulating; at the same time, the film has uneven thickness, uneven density, and uneven surface.

Embodiment 3

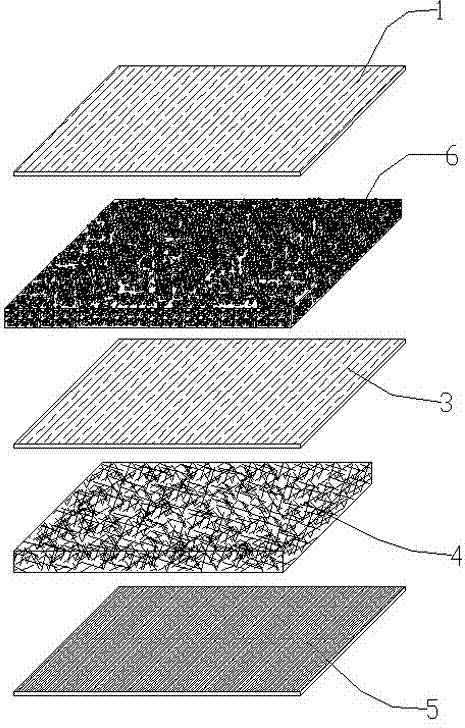

[0021] A sound-absorbing structure such as image 3 The sound-absorbing material body is composed of a fiber material layer 4 and a foam material layer 6, and a film 3 is arranged between the fiber material layer and the foam material layer. The film can be made of one of PP, PE, PET, and EVA materials. A soft film made of a material or a variety of processes or an air-blocking skin formed when a foamed material is foamed. The outer side of the fiber material layer is provided with a soft film 1 processed from one of PP, PE, PET, EVA materials, or a mixture of multiple materials. The outer side of the foam material layer is provided with an airflow barrier formed by processing one of PP, PE, PET, and EVA materials, or a mixture of multiple materials, or formed when the foam material is foamed. A soft film formed from the epidermis5.

[0022] The foam material layer 6 can be made of open and / or partially open foam material. The opening ratio of the foam material can be adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com