Helium-filled system for removing grains in gas

A particle removal technology, which is applied in the field of nuclear power plant safety and environmental protection, can solve the problems of low power of electrostatic precipitator, affecting the safety of the surrounding environment, and poor removal effect of fine particles, so as to achieve simple control, convenient implementation and protection of the public Health and Environmental Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

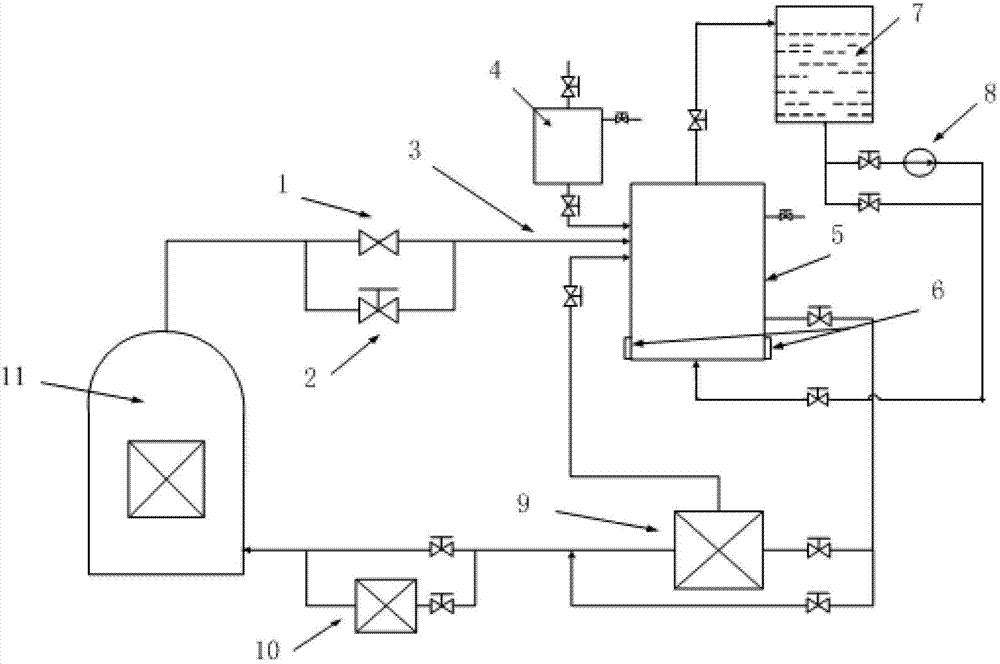

[0024] The present invention provides a helium-filled gas particle removal system. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

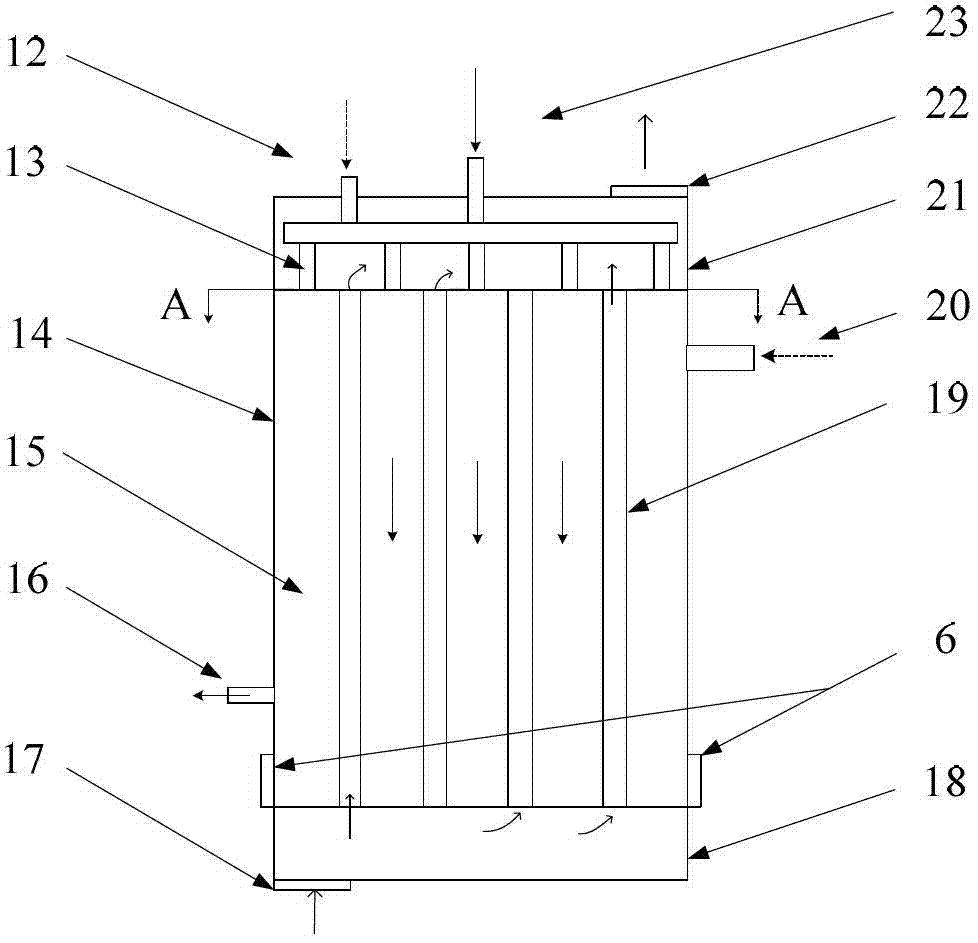

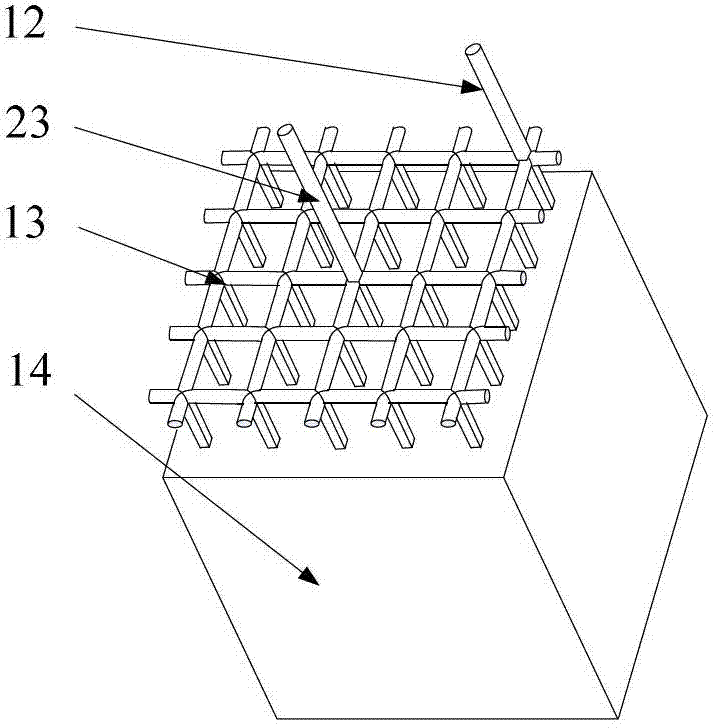

[0025] The core part of the system is the helium tank 5, and its structure is as follows figure 2 As shown: the helium tank 5 is divided into three parts from top to bottom: the upper header 21, the helium tank body 14 and the lower header 18; a number of staggered particle removal channels 15 are arranged in the helium tank body 14 and water cooling channel 19 (as Figure 4 ), the upper part of the side wall of the helium tank box body 14 is provided with a helium gas filling port 20, and the lower part is provided with an exhaust port 16; a grid-shaped intake pipe 13 is provided in the upper header 21, and the intake pipe 13 has two inlets and several outlets, the two inlets are respectively the air inlet 23 at the center and the helium gas return port 12 at the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com