Disc type three-phase magnetic gathering type transverse magnetic field permanent magnet motor

A technology of transverse magnetic field and permanent magnet motor, which is applied to synchronous motors with stationary armature and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., and can solve the problems of low utilization rate of permanent magnets , to achieve the effect of reducing the axial volume and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

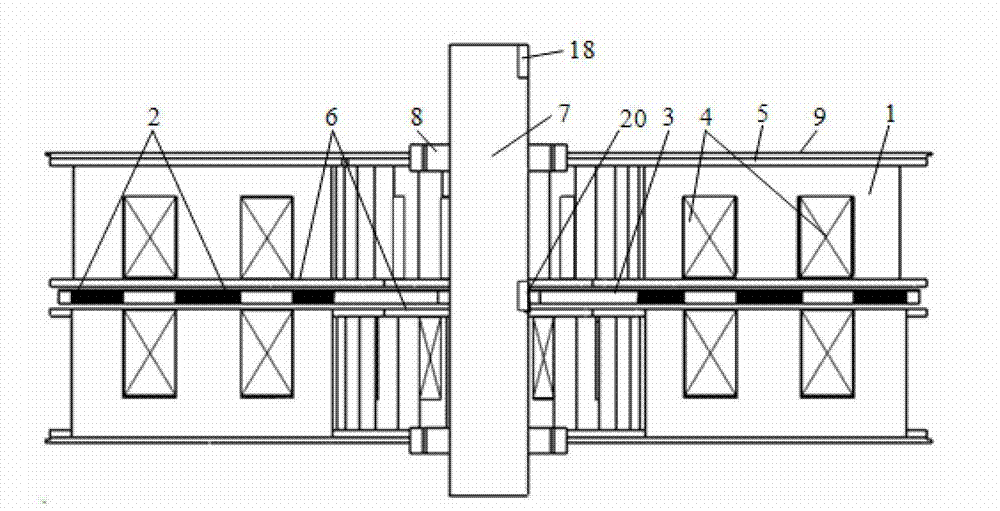

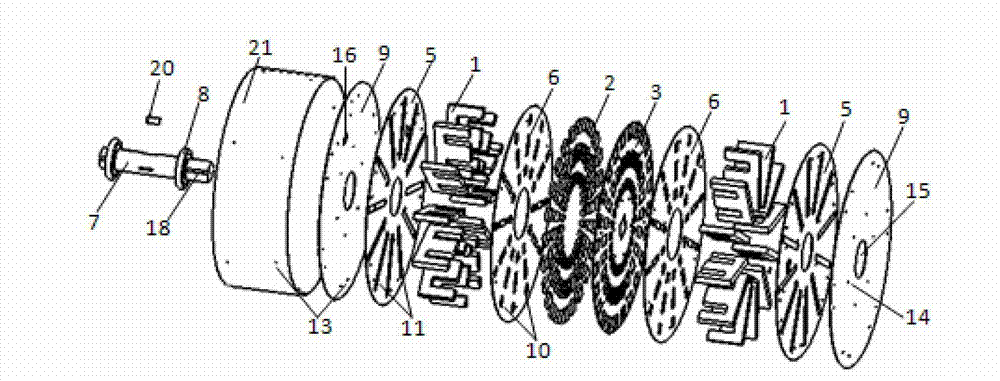

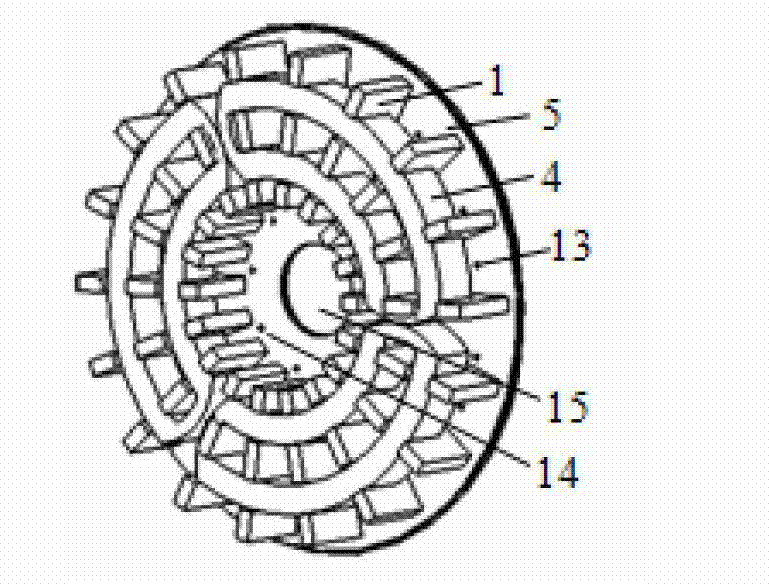

[0014] The following examples refer to Figure 1~5 .

[0015] The disc-type three-phase magnetism-concentrating transverse magnetic permanent magnet motor of the present invention includes E-type silicon steel 1, permanent magnet 2, permanent magnet panel 3, winding 4, E-type silicon steel auxiliary plate 5, winding auxiliary plate 6 and rotating shaft 7.

[0016] The shape of the motor is disc-shaped, and the radial dimension of the motor is larger than the axial dimension, which is similar to the shape of the hub of an automobile. The motor is composed of E-type silicon steel 1, permanent magnet 2, permanent magnet panel 3, winding 4, E-type silicon steel auxiliary plate 5, winding auxiliary plate 6, rotating shaft 7, bearing 8, end plate 9, and shell 21. The rotor disk composed of permanent magnets 2 and permanent magnet panels 3 is located in the middle of the stator structure on both sides, and is fixed on the rotating shaft 7 by clips 20; the shell 21 and the single-sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com