Salty taste enhancer and kelp extract comprising the same

A technology of kelp extract and enhancer, applied in the field of food or beverage, can solve the problems of unsuitability and no disclosure of the salty taste enhancement effect or flavor enhancement effect of flavor components, and achieve the effect of enhancing the salty taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

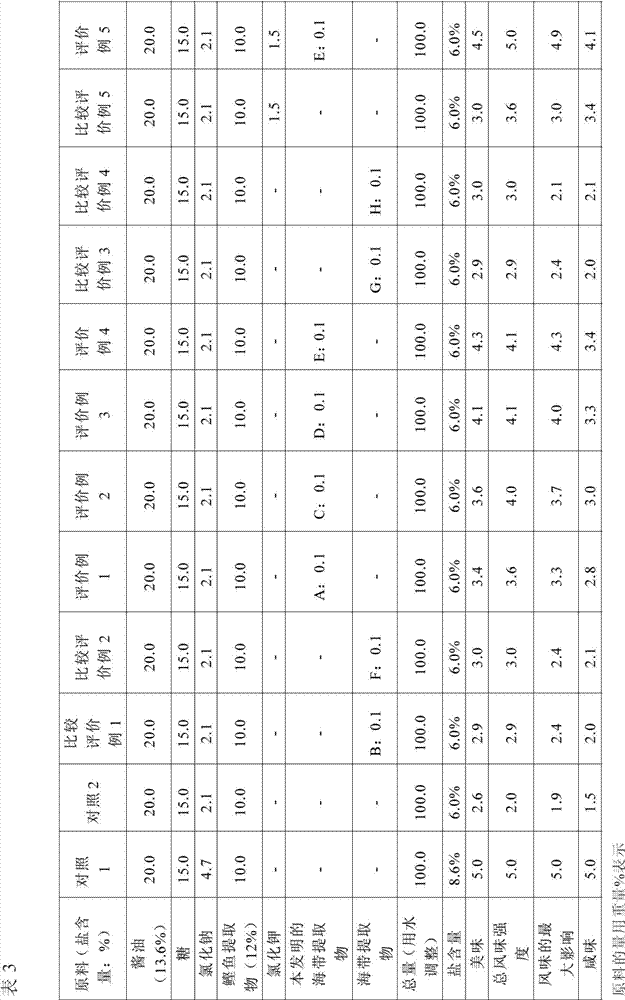

[0082] 500 g of water and 50 g of dried kelp (Laminaria angustatata, produced by Maruhachi Muramatsu Co., Ltd.) were charged in a sealed heating pot equipped with a condenser tube, and heated. After the temperature reached 100° C., heating was continued for 120 minutes with stirring. The vapors thus produced are captured by condenser tubes. Thus, 150 g of the liquid distillate was caught, and this liquid distillate was called kelp spice P. The content of the volatile components derived from the kelp in the liquid distillate was 30.0 ppm relative to the kelp as the raw material.

[0083] After cooling the extract portion in the pot to room temperature, the captured kelp spice P was returned to the pot, and the mixture was stirred for 10 minutes. After removing the extraction residue, 350 g of Laminaria extract A was obtained.

Embodiment 2

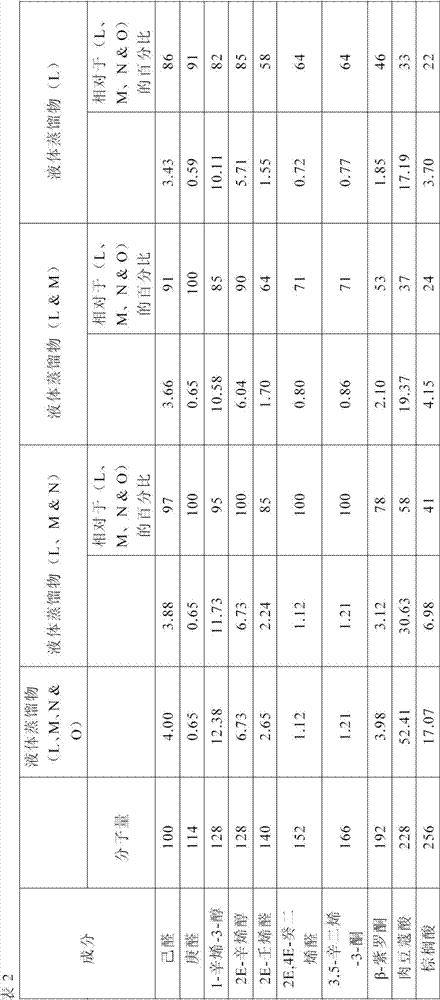

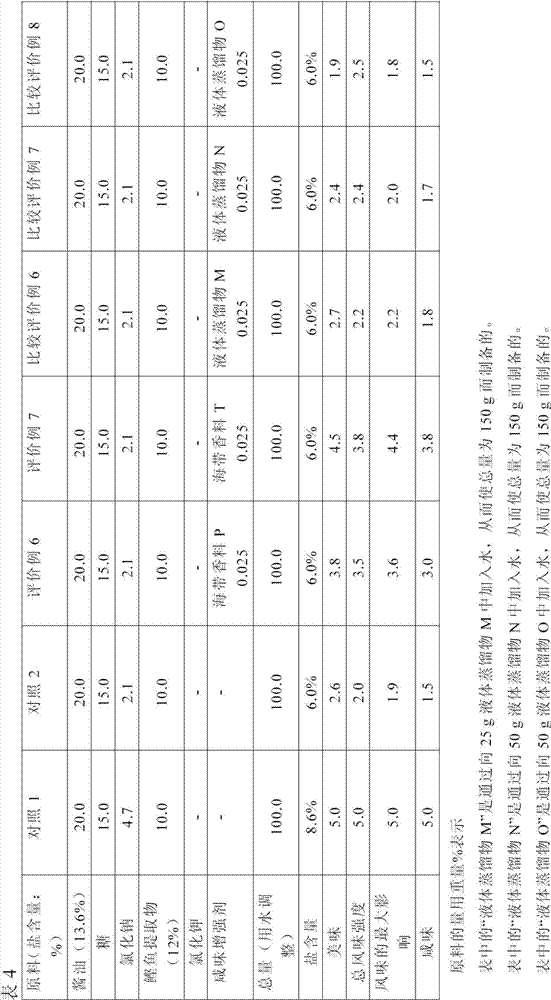

[0087] 500 g of water, 50 g of dried kelp (Laminaria angustatata, produced by Maruhachi Muramatsu Co., Ltd.), 0.5 g of protease (Protease A "Amano" G, produced by Amano Enzyme Co., Ltd. Co., Ltd.), 0.3 g of cellulase (Cellulosin AC40, produced by HBI Enzymes Co., Ltd.), and 0.2 g of glutaminase (Glutaminase Daiwa SD-C100S, produced by Amano Enzyme Co., Ltd.), and heated with stirring. Laminaria was subjected to enzyme treatment for 16 hours while maintaining at 40°C. Next, the temperature was raised to 100° C., and heating was continued for 120 minutes. The vapors thus produced are captured by condenser tubes. Let the first part with a weight of 25 g be called liquid distillate L, the second part with a weight of 25 g be called liquid distillate M, the third part with a weight of 50 g be called liquid distillate N, and the final weight be The 50 g portion is called liquid distillate O. The mixture of liquid distillates L and O is called Kelp Spice Q. After cooling the extr...

Embodiment 3

[0109] Using the same method as in Example 2, 25 g of liquid distillate L, 25 g of liquid distillate M, 50 g of liquid distillate N, and 50 g of liquid distillate O were obtained. The mixture of liquid distillates L, M and N with 50 g of water is called Kelp Spice R.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com