Improved method and apparatus for forming corrugated board

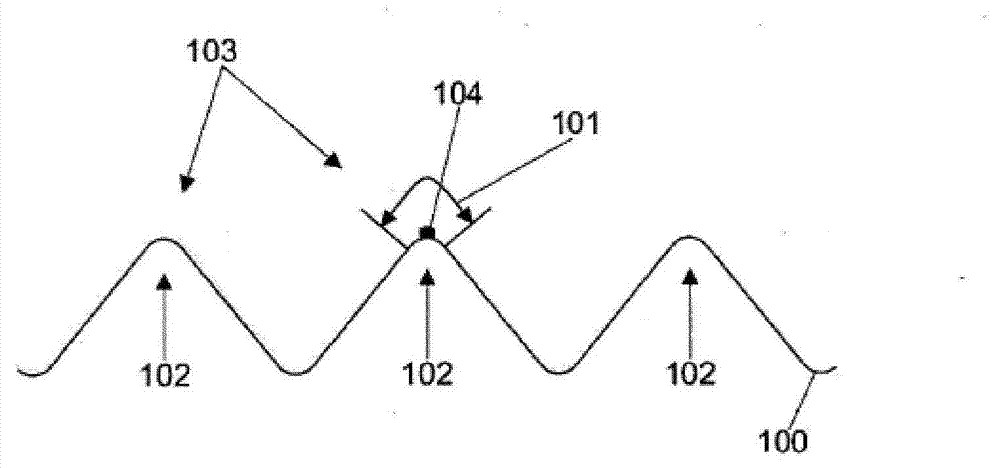

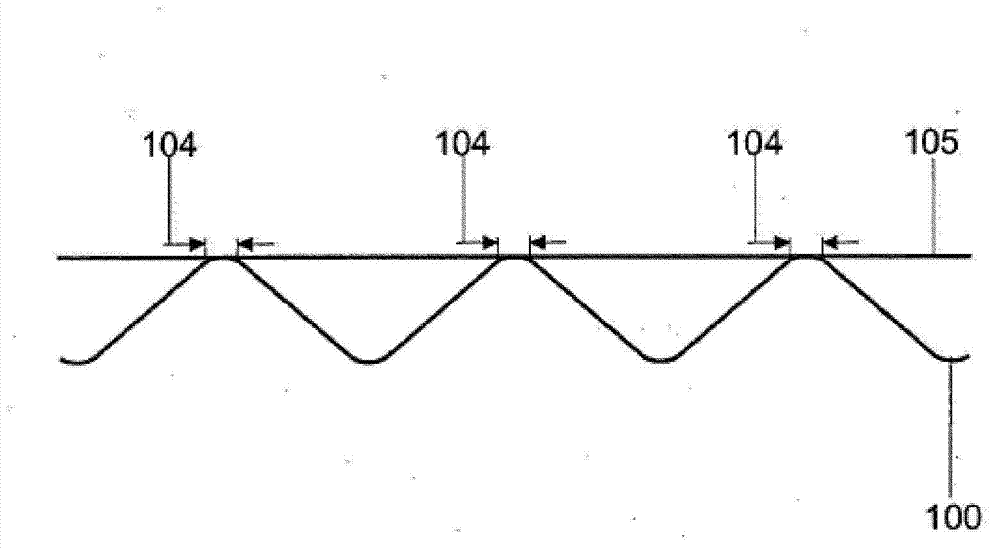

An equipment and corrugated technology, applied in the field of improved models and equipment for forming corrugated sheets, can solve problems such as damage to corrugated sheet corrugations and reduction of board strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

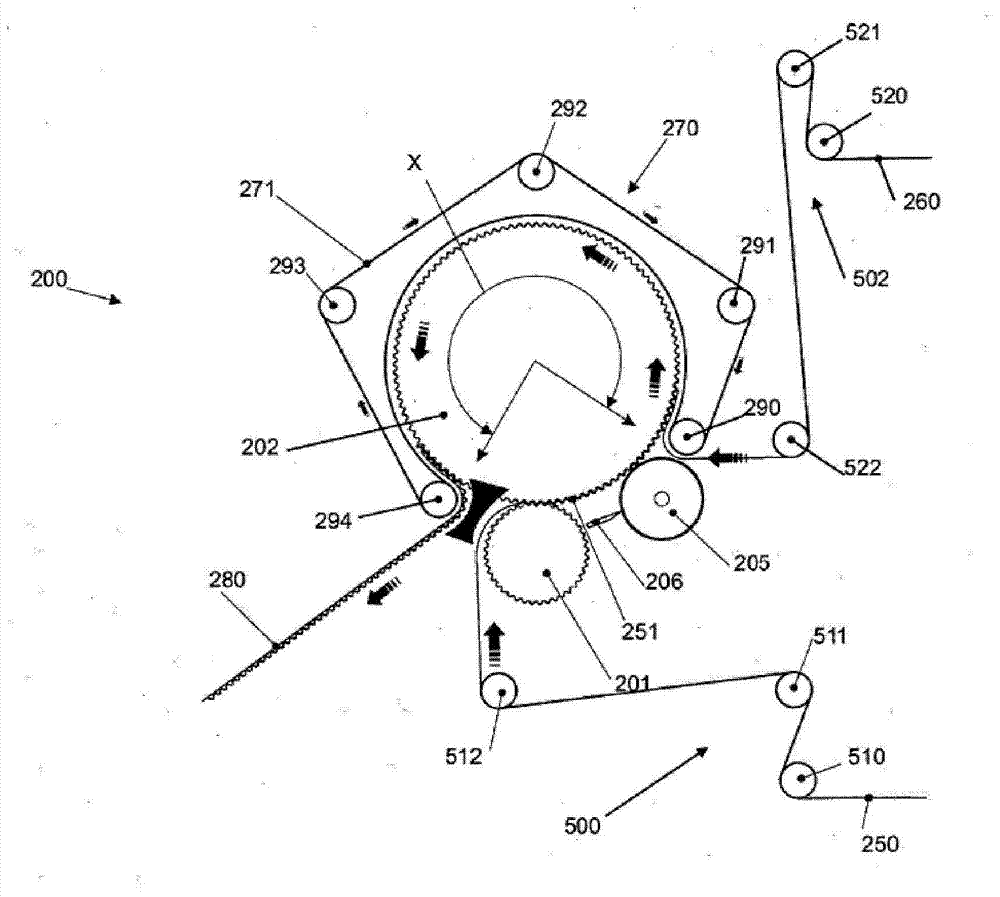

[0317] In order to calculate the productivity of the 1.6m diameter second fluted (ie, large) roller, in which the endless belt extends 76% around the second roller, the new formula RP=DHT / BT of the present invention is applied, which gives 0.76(π1. 6) / 0.05 RP (productivity), equal to 76m / min productivity, where 0.05 minutes is 3 seconds bonding time. This productivity is significantly lower than the productivity calculated by the applicant in WO2009 / 000085.

Embodiment 2

[0319] If the manufacturer needs a productivity of 143m / min and uses a glue with a BT of 0.033333 minutes (ie 2s), the new formula DHT of the present invention can be applied to express the diameter of the second flute (ie larger) roller as 0.93 x(π2r), and the diameter can be calculated by DHT=RP.BT, it will be (143×0.033333). Then, in order to obtain the diameter, the equation 0.93x(π2r)=(143×0.033333) is reorganized, so that 2r (that is, the diameter)=((143×0.033333) / 0.76) / π, which is equal to the diameter of 2m.

Embodiment 3

[0321] If you want to calculate the productivity of a 2m diameter roller, where BT is 0.05 minutes (ie, 3s). Apply the formula RP=DHT / BT 0.93(π2) / 0.05, which is equal to 116m / min.

[0322] In practice, the diameter of 2m is at or close to the limit that a pair of intermeshing fluted rollers can produce corrugated cardboard: as described in this article and in figure 2 Or as described in the applicant’s previous PCT application WO2009 / 145642. The reason why it is impossible in practice to have a large fluted roller with a diameter significantly greater than 2m (for example, a roller with a diameter of 2.5m, 3m or larger) is that the increased weight of such a roller makes it difficult to lift and move , Especially when it comes to the manufacture, maintenance and repair of such large rollers. Furthermore, rollers with a diameter greater than 2 m are heavier and require significantly more energy to rotate the rollers, and therefore increase production costs. Moreover, maintainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com