Gas barrier laminate and packaging material

A gas-barrier laminate and gas-barrier layer technology, used in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as reduced incineration efficiency, clogging of exhaust ports or furnace interiors by incineration residues, and generation of dioxins, etc. , to achieve excellent gas barrier properties, less environmental load, and the effect of inhibiting immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

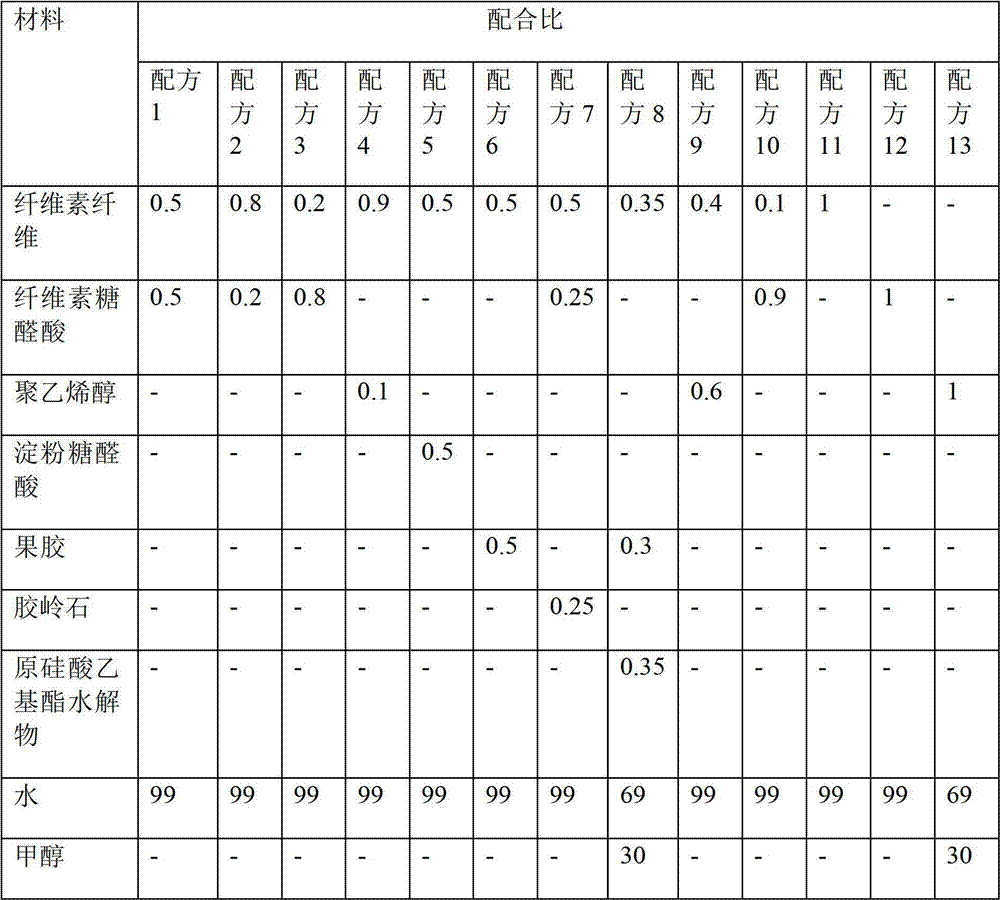

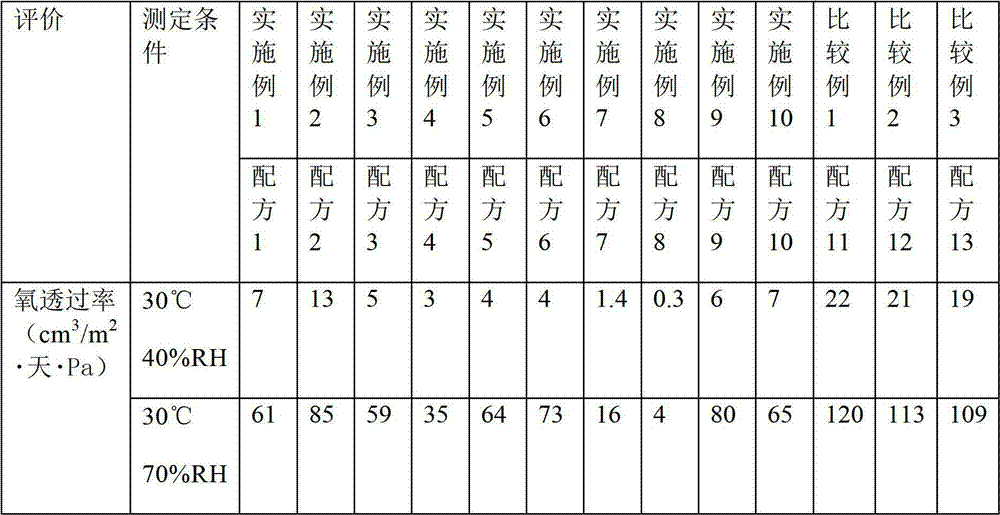

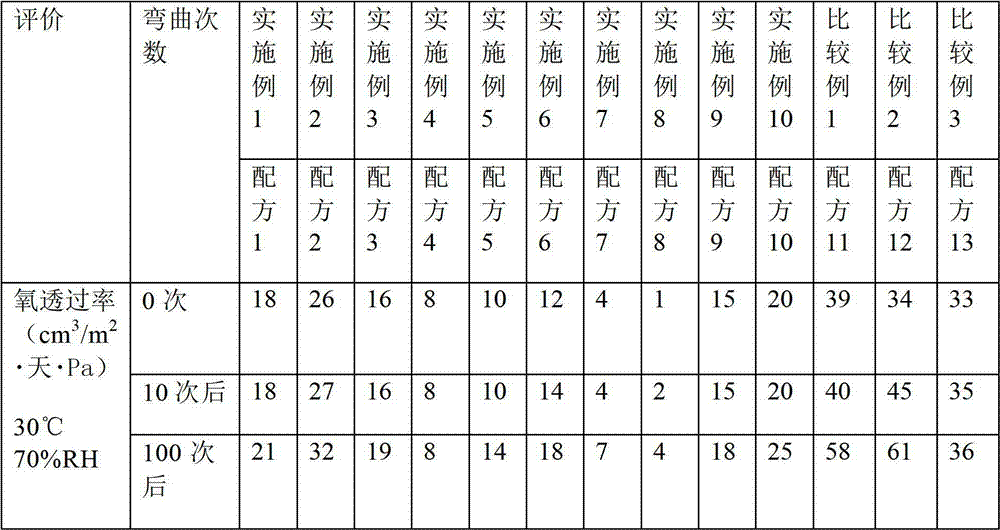

[0091] [Manufacture of Gas Barrier Films in Examples 1 to 10]

[0092] On a substrate of polyethylene terephthalate film (Lumila-P60, manufactured by Toray Co., Ltd.) with a thickness of 12 μm, it was prepared by bar coating at the compounding ratios shown in Formulations 1 to 10 in Table 1. The coating solution was prepared to have a film thickness of 0.2 μm, and then dried to form a gas barrier layer to produce a gas barrier film.

[0093] [Manufacture of gas barrier film for packaging materials in Examples 1 to 10]

[0094] Furthermore, in order to use the produced gas barrier film as a packaging material, the heat-seal layer was laminated on the side of the gas barrier layer via the adhesive layer for lamination by dry lamination, and left at 50°C for 4 days to produce a package. The material uses a gas barrier film. As the heat-sealing layer, a linear low-density polyethylene film (TUX-FCS, manufactured by Toseiro Co., Ltd.) with a thickness of 50 μm was used, and as an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com