Piezoelectric thin-film element, process for producing same, and piezoelectric thin-film device

A piezoelectric film and device technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, etc., can Solve the problems of characteristic deviation deterioration, the influence of size cannot be ignored, etc., and achieve the effect of excellent piezoelectric characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] Embodiments of the present invention are described below.

Embodiment 1)

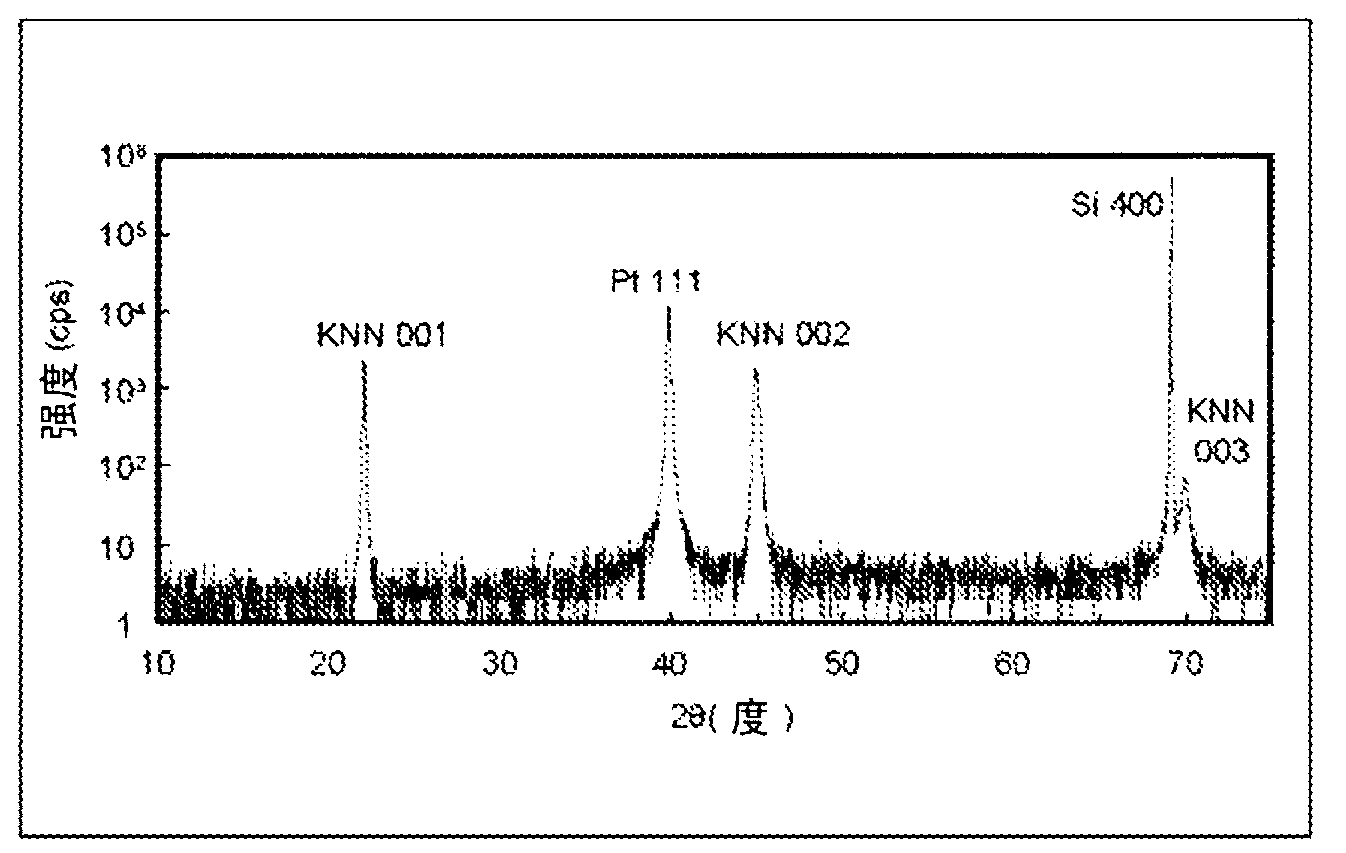

[0117] use Figure 1~Figure 8 illustrate.

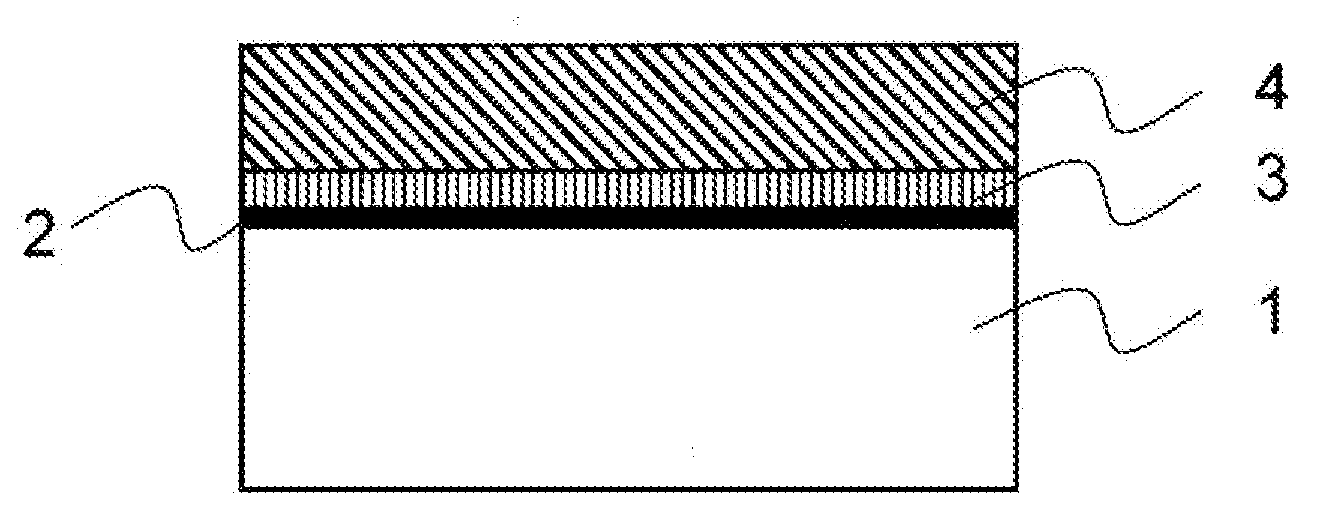

[0118] figure 1 A cross-sectional view showing an overview of a substrate with a piezoelectric thin film. In this embodiment, an adhesive layer 2 is formed on a Si substrate 1 having an oxide film, and a lower electrode layer 3 and a piezoelectric thin film layer 4 of KNN with a perovskite structure are sequentially formed on the upper portion of the adhesive layer 2. Piezoelectric thin film devices.

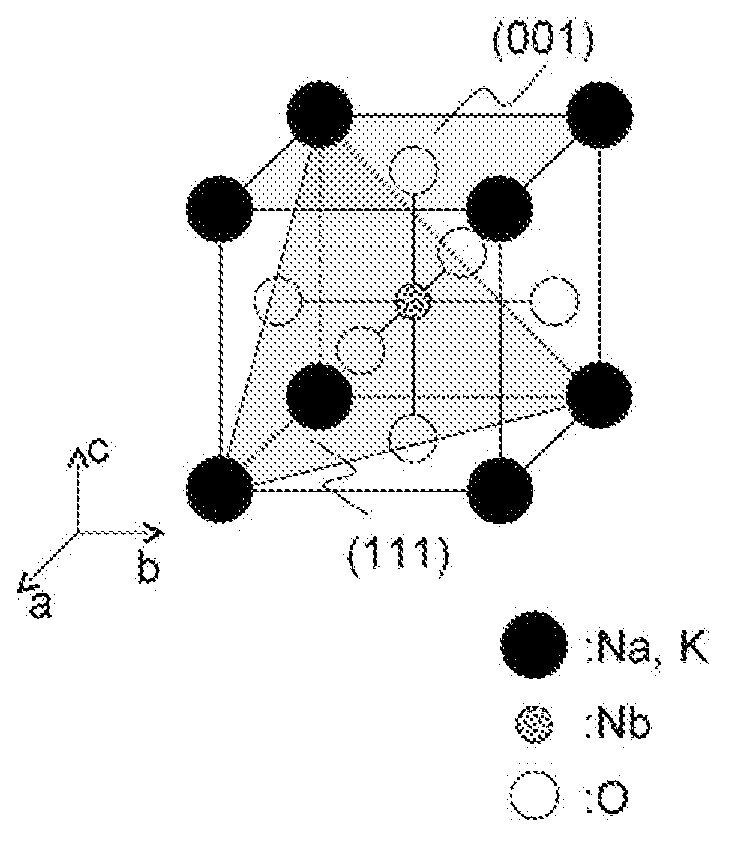

[0119] At this time, the crystal system of the piezoelectric film layer 4 is quasi-cubic or tetragonal or orthorhombic, and at least a part of the piezoelectric film layer 4 can be ABO 3 crystalline or amorphous or a mixture of the two. Here, A is one or more elements selected from Li, Na, K, La, Sr, Nd, Ba, and Bi, and B is an element selected from Zr, Ti, Mn, Mg, Nb, Sn, Sb, Ta, and One or more elements in In, O is oxygen. Pb-containing piezoelectric material may be used as the A-site piezoelectric material, but a Pb-free piez...

Embodiment 2)

[0144] use Figure 9~Figure 10 illustrate.

[0145] Next, when accurately calculating the diffraction intensity ratio of the (001) orientation component and the (111) orientation component, it is necessary to discuss the correction values of the respective X-ray diffraction intensities. For this purpose, the pole figures of (001) and (111) are investigated.

[0146] Figure 9 Displays the simulation results for the pole figure. Figure 9 (a) is a simulation result of a pole figure with (001) as a pole. As shown in this figure, it can be seen that the (110) diffraction of the (001) oriented KNN contributes 4 equivalent diffractions. At this time, the correction factor is considered to be 4. On the other hand, by Figure 9 (b) The simulation results using (111) as the pole figure, it can be seen that the (110) diffraction of the (111)-oriented KNN contributes 3 equivalent diffractions, so the correction factor is 3. Therefore, when the volume fraction of (001) orientati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com