Imidacloprid sustained-release granules and preparation and application thereof

A technology of slow-release granules and imidacloprid, which is applied in the field of pesticide technology and plant protection, can solve the problems of slow production time and achieve the effects of fast production speed, wide sources and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 0.5% imidacloprid sustained-release granules

[0034] (1). 50g of imidacloprid, 50g of detergent LS, 20g of calcium lignosulfonate, 20g of sodium lauryl sulfate, and 9750g of diatomaceous earth. Add to the granulation pan, stir well, spray water, prepare 2-5 mm round granules, and dry for later use; (2). Spray 50% epoxy resin-SK curing agent for coating, and heat to 100 ℃ ~ 120 ℃ curing; the curing time is 10 ~ 15 minutes, and the product can be obtained after the coating agent is cured.

[0035] The mass percentage of the mass of water described in step (1) and soil ball mass is 2%~15%;

[0036] The speed of the heatable disc granulator in step (1) and step (2) is 20-120 r / min.

[0037] The coating amount described in step (2) is 2.5%;

Embodiment 2

[0038] Example 2 Preparation of 1.0% imidacloprid sustained-release granules

[0039] (1). Imidacloprid 100g, detergent LS 80g, calcium lignosulfonate 60g, sodium lauryl sulfate 100g, methylcellulose 50g, bentonite to make up 9800g. Add to the granulation tray, stir well, spray water, prepare 2-5 mm round granules, dry and set aside;

[0040] (2). Spray 50% epoxy resin - SK curing agent and urea-formaldehyde resin for coating, and heat to 100 ℃ ~ 120 ℃ for curing; the curing time is 10 ~ 15 minutes, and the product can be obtained after the coating agent is cured.

[0041] The mass percentage of the mass of water described in step (1) and soil ball mass is 2%~15%;

[0042] The speed of the heatable disc granulator in step (1) and step (2) is 20-120 r / min.

[0043] The coating amount described in step (2) is 2%;

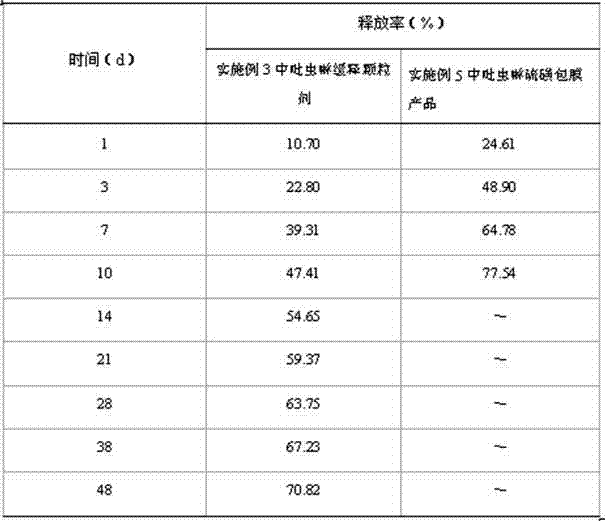

Embodiment 3

[0044] Example 3 Preparation of 2.0% imidacloprid sustained-release granules

[0045] (1). Imidacloprid 200g, detergent LS 80g, calcium lignosulfonate 50g, sodium lauryl sulfate 50g, bentonite 40g, methylcellulose 50g, kaolin supplement 9750g. Add to the granulation tray, stir well, spray water, prepare 2-5 mm round granules, dry and set aside;

[0046] (2). Spray 50% epoxy resin - SK curing agent for coating, and heat to 100 ℃ ~ 120 ℃ for curing; the curing time is 10 ~ 15 minutes, and the product can be obtained after the coating agent is cured.

[0047] The mass percentage of the mass of water described in step (1) and soil ball mass is 2%~15%;

[0048] The speed of the heatable disc granulator in step (1) and step (2) is 20-120 r / min.

[0049] The coating amount described in step (2) is 2.5%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com