Method for enhancing rigidity and dimensional stability of injection-molded element and surface shell of liquid crystal display television

A dimensional stability, liquid crystal TV technology, applied in the direction of TV, color TV, color TV parts, etc., can solve the problem that the rigidity and dimensional stability are difficult to meet the requirements of flat-panel TV thinning and narrow frame, narrow frame and so on , to achieve the effect of enhanced mechanical properties, good heat resistance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

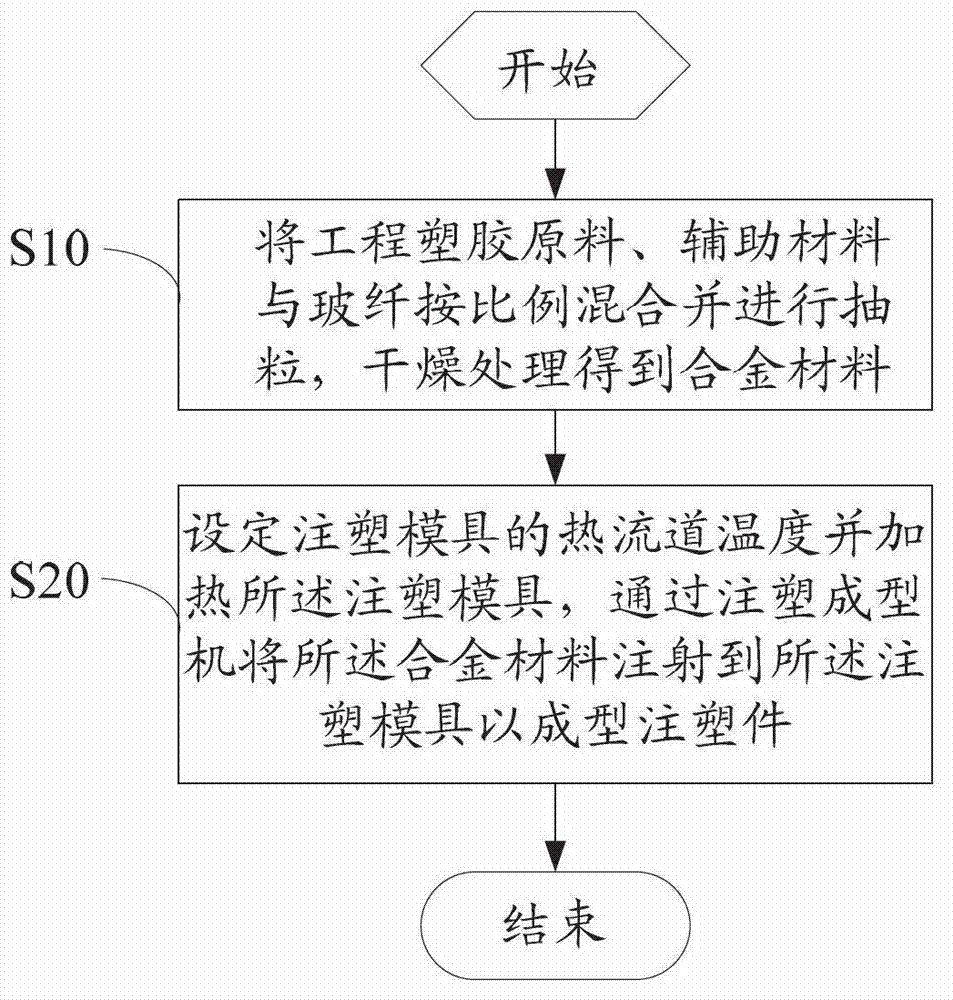

[0038] The invention provides a method for improving the rigidity and dimensional stability of injection molded parts, referring to figure 1 As shown, in the embodiment of the present invention, the method includes the following steps:

[0039] Step S10, mixing engineering plastic raw materials, auxiliary materials and glass fibers in proportion, granulating, and drying to obtain alloy materials; in the embodiment of the present invention, engineering plastic raw materials refer to ABS and PC pellets, and glass fiber refers to glass Fiber (Glass Fiber, GF) particles, auxiliary materials are some small proportion materials that play an anti-oxidation or lubricating role during material synthesis, such as antioxidants or antioxidants and lubricants (such as phosphate esters).

[0040] Step S20, setting the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com