Composite book type sterilizing film and production process thereof

A production process and rewriting technology, applied in the field of polymer material processing and application, can solve the problems of not developing the effect of sterilization, products are easily polluted, disadvantageous, etc., to increase the reuse rate, avoid the spread of diseases, and achieve market prospects. huge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

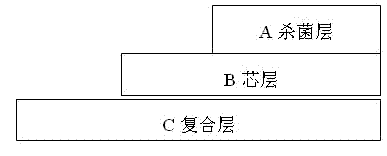

[0044] Such as figure 1 As shown, the complex-type bactericidal film is divided into A, B, and C three-layer structure, A layer is the bactericidal layer, B layer is the core layer, and C layer is the composite contact layer, of which:

[0045] Layer A: 92% polypropylene + 5% antibacterial masterbatch + 3% anti-blocking agent;

[0046] Layer B: 97% polypropylene + 3% antistatic smooth masterbatch;

[0047] Layer C: 96% polypropylene + 4% anti-blocking agent.

[0048] The thickness of the copy-type bactericidal film is 8um.

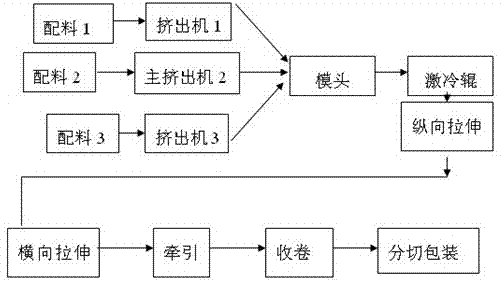

[0049] Such as figure 2 As shown, the Fushu type sterilization film production process includes the following steps:

[0050] (1) Feeding system:

[0051] The raw materials of layer A, layer B, and layer C are respectively added to the mixing bin according to the above ratio, mixed evenly by stirring, weighed and measured, and then enter the main extruder and auxiliary extruder.

[0052] (2) Melt extrusion:

[0053] The heating zones of the main ex...

Embodiment 2

[0070] Such as figure 1 As shown, the complex-type bactericidal film is divided into A, B, and C three-layer structure, A layer is the bactericidal layer, B layer is the core layer, and C layer is the composite contact layer, of which:

[0071] Layer A: 93% polypropylene + 4% antibacterial masterbatch + 3% anti-blocking agent;

[0072] Layer B: 98% polypropylene + 2% antistatic smooth masterbatch;

[0073] Layer C: 97% polypropylene + 3% anti-blocking agent.

[0074] The thickness of the complex-type bactericidal film is 11um.

[0075] Such as figure 2 As shown, the Fushu type sterilization film production process includes the following steps:

[0076] (1) Feeding system:

[0077] The raw materials of layer A, layer B, and layer C are respectively added to the mixing bin according to the above ratio, mixed evenly by stirring, weighed and measured, and then enter the main extruder and auxiliary extruder.

[0078] (2) Melt extrusion:

[0079] The heating zones of the mai...

Embodiment 3

[0095] Such as figure 1 As shown, the complex-type bactericidal film is divided into A, B, and C three-layer structure, A layer is the bactericidal layer, B layer is the core layer, and C layer is the composite contact layer, of which:

[0096] Layer A: 94% polypropylene + 3% antibacterial masterbatch + 3% anti-blocking agent;

[0097] Layer B: 99% polypropylene + 1% antistatic smooth masterbatch;

[0098] Layer C: 98% polypropylene + 2% anti-blocking agent.

[0099] The thickness of the copy-type bactericidal film is 15um.

[0100] Such as figure 2 As shown, the Fushu type sterilization film production process includes the following steps:

[0101] (1) Feeding system:

[0102] The raw materials of layer A, layer B, and layer C are respectively added to the mixing bin according to the above ratio, mixed evenly by stirring, weighed and measured, and then enter the main extruder and auxiliary extruder.

[0103] (2) Melt extrusion:

[0104] The heating zones of the main e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com