Advanced operating method for underflow pump of ore pulp pipeline transportation system

A technology of pipeline transportation and underflow pump, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of high labor intensity, wear of small circulation pipelines, large deviation of slurry concentration, etc., and reduce the labor intensity of workers. , the effect of reducing frequency and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Change process:

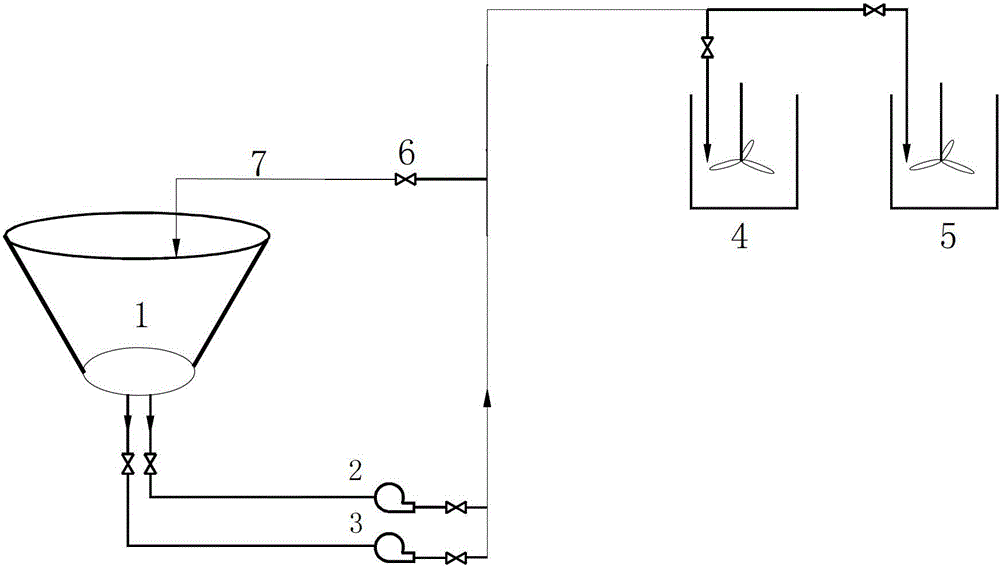

[0024] The HV1084 valve 6 on the small circulation pipeline 7 is shifted from the top of the 16-meter-high stirring tank (4, 5) to the 6-meter-high platform, reducing the impact of the ore slurry on the top of the stirring tank (4, 5) and the thickening tank 1 The wear and tear of the small circulation pipeline 7.

[0025] Guanlai Mine:

[0026] It is necessary to observe the incoming ore concentration and its operation series of the concentrator in a timely manner. Determine whether to open the HV1084 valve 6 to switch the small cycle according to the incoming ore concentration of the concentrator and its operation series.

[0027] When the concentrator is in normal operation, that is, the incoming ore concentration is 30-45%, four series of operations, the HV1084 valve 6 should always be in the closed position, the underflow pump 2, 3 continuously injects the slurry with a qualified concentration into the stirring tank 4, 5, and the small cycle st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com