Process and system for extracting erythritol

A technology of erythritol and extraction process, which is applied in the field of extraction process and system of erythritol, and can solve the problems of unstable late stage process, low concentration of material liquid, large water consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

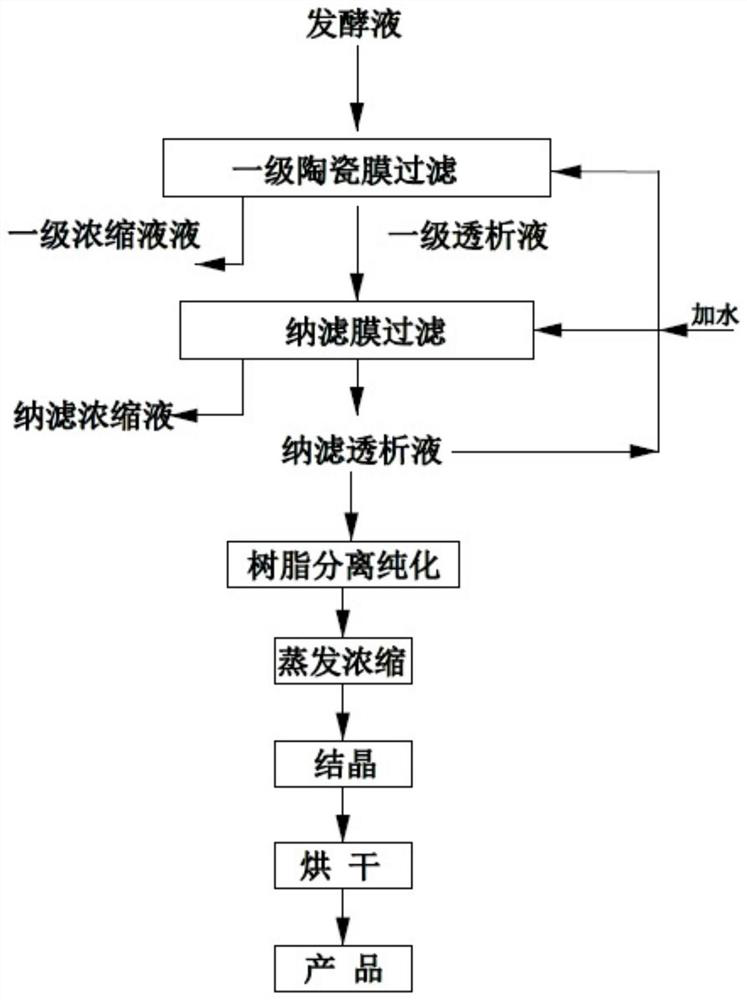

[0044] Such as figure 1 Shown, the invention discloses a kind of extraction process of erythritol, it comprises the following steps:

[0045] S1. Ceramic membrane filtration: the erythritol fermentation broth is eluted and filtered through a primary ceramic membrane to obtain a primary dialysate and a primary concentrated solution. The pore size of the primary ceramic membrane is 50-200nm.

[0046] S2. Nanofiltration filtration: the primary dialysate in step S1 is eluted and filtered through a nanofiltration membrane to obtain a nanofiltration dialysate and a nanofiltration concentrated solution. The molecular weight cut-off of the nanofiltration membrane is 200-1000 Daltons.

[0047] S3. Nanofiltration graded treatment: real-time detection of erythritol concentration on the nanofiltration dialysate in step S2, and graded treatment:

[0048] If the nanofiltration dialysate concentration is less than 13%, return to the aforementioned process for processing.

[0049] If the co...

Embodiment 2

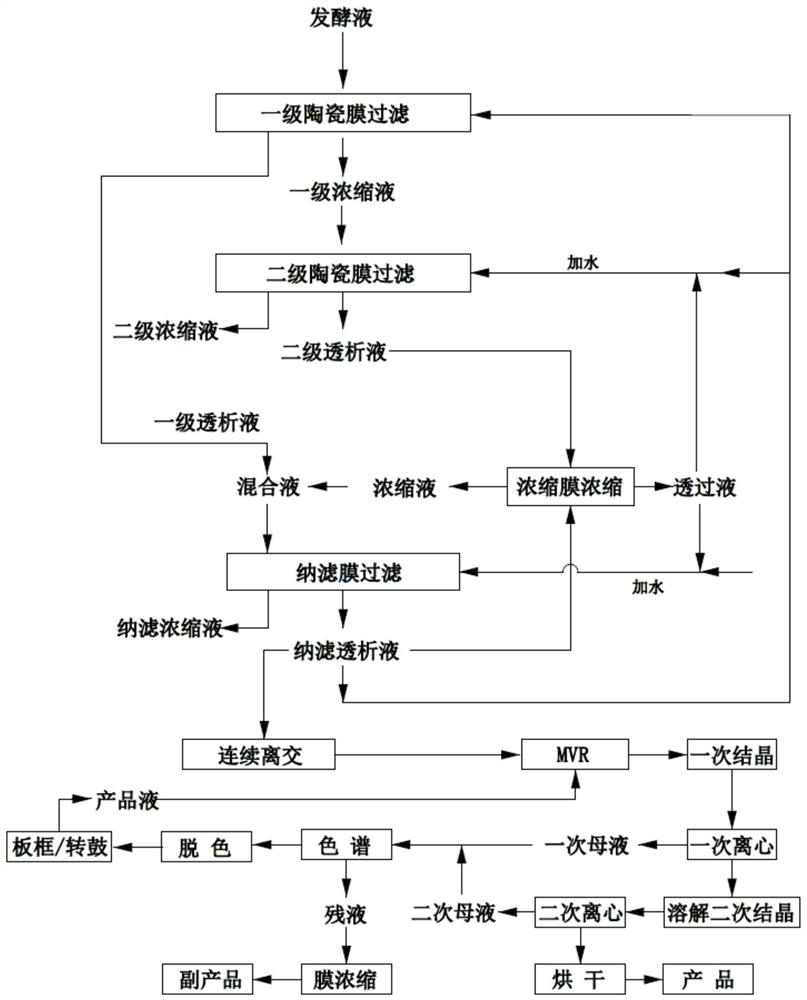

[0052] Such as figure 2 Shown, the invention discloses a kind of extraction process of erythritol, it comprises the following steps:

[0053] S1, ceramic membrane filtration: pass the fermentation broth of erythritol (concentration 15%-20%, light transmittance>2%, electrical conductivity2%, conductivity 2%, electrical conductivity<2000μs / cm, PH3-5). The secondary concentrate is used as waste liquid for later treatment.

[0054] S2. Concentration: Concentrate the secondary dialysate in step S1 through a nanofiltration membrane with a molecular weight cut-off of less than 100 Daltons to obtain a concentrated solution (refraction ≥ 15%, light transmittance > 2%, conductivity 90%, conductivity < 200μs / cm). The permeate can be recycled for elution in the secondary ceramic membrane in step S1 and the nanofiltration membrane in step S3.

[0055] S3, nanofiltration filtration: the primary dialysate in step S1 and the concentrated solution in step S2 are eluted and filtered through...

Embodiment 3

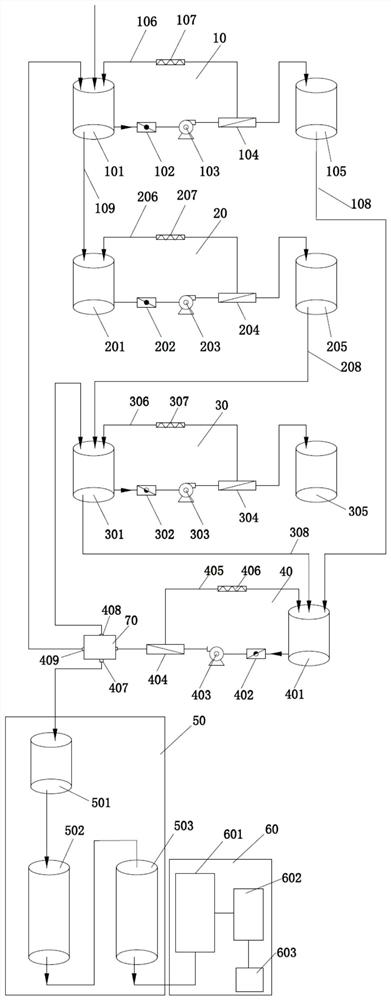

[0062] Such as image 3 As shown, the present invention also discloses an extraction system of erythritol, which includes: a first-level ceramic membrane filtration device 10 connected to each other through pipelines, a secondary ceramic membrane filtration device 20, a membrane concentration device 30, and a nanofiltration membrane Purification device 40 , resin separation and purification device 50 and concentration and crystallization system 60 . The first-level concentration pipeline 109 of the first-level ceramic membrane filtration device 10 is connected with the second-level ceramic membrane filtration device 20, and the second-level dialysis pipeline 208 of the second-level ceramic membrane filtration device 20 is connected with the membrane concentration device 30; The primary dialysis pipeline 108 of concentrated pipeline 308 and primary ceramic membrane filtration device 10 is connected with nanofiltration membrane purification device 40 respectively; Classificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com