Efficient vacuum cleaning machine

A vacuum cleaning machine and high-efficiency technology, applied in the field of cleaning machines, can solve the problems of reduced cleaning effect, difficult to control cleaning quality, difficult to develop ultrasonic cavitation effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

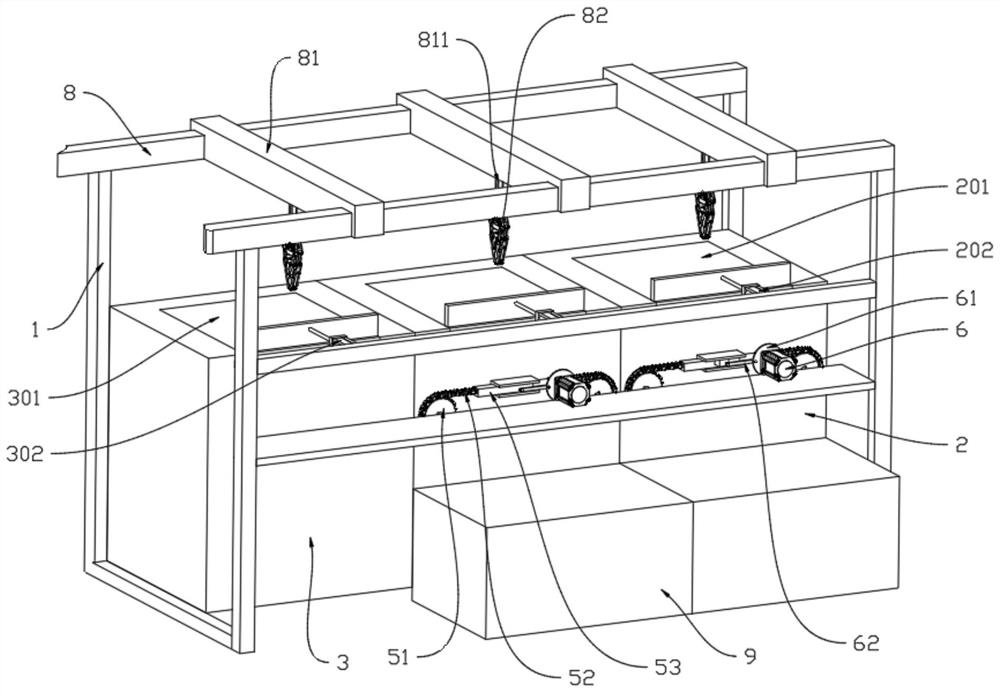

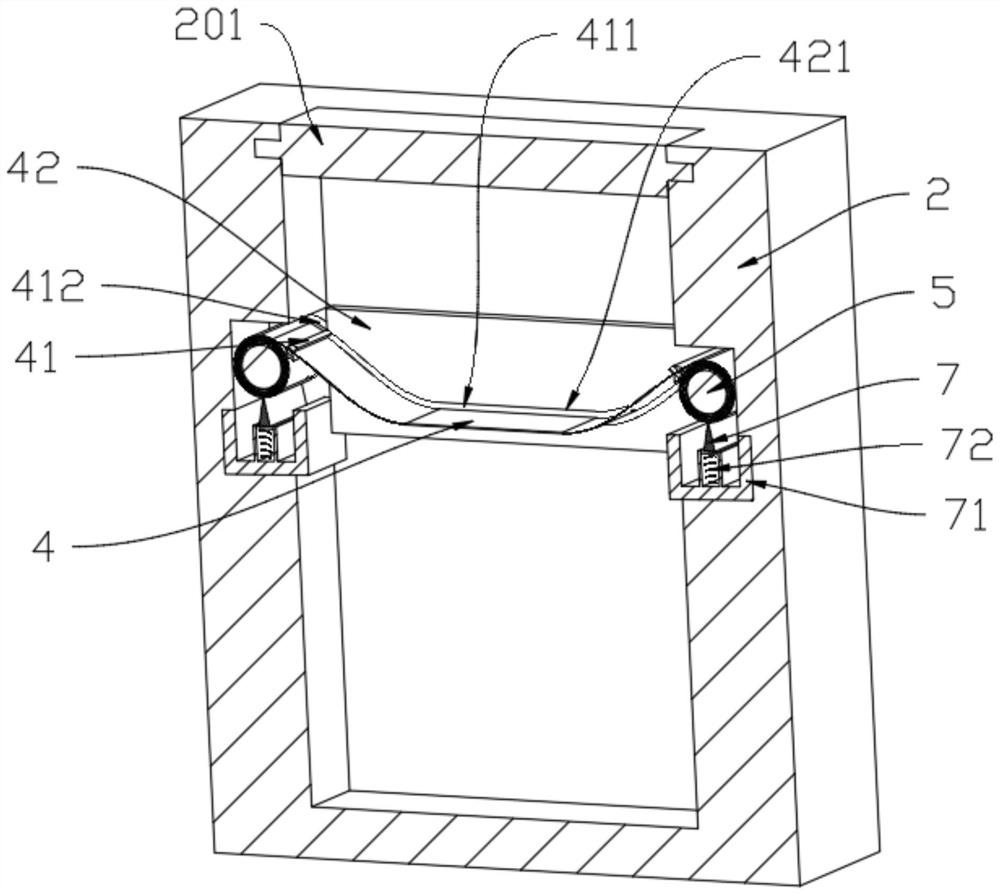

[0054] A high-efficiency vacuum cleaner, such as figure 1 Shown includes a frame 1 on which at least one first cleaning chamber 2 and a second cleaning chamber 3 are fixedly connected, and the second cleaning chamber 3 is arranged on the same side of each first cleaning chamber 2 . Each first cleaning chamber 2 and the second cleaning chamber 3 are horizontally arranged, and the top of the first cleaning chamber 2 is slidably connected with a first hatch 201 for opening or closing the first cleaning chamber 2, and the first hatch 201 is provided with There is a first driving member 202 for driving the first cabin door 201 to slide relative to the first cleaning chamber 2 . The top of the second cleaning chamber 3 is slidably connected with a second hatch 301 for opening or closing the second cleaning chamber 3 , and the second hatch 301 is provided with a door for driving the second hatch 301 to slide correspondingly to the second cleaning chamber 3 . The second driver 302 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com