General LED (light-emitting diode) bulb composition method and liquid fluorescent flange fixing type LED bulb

A kind of LED light bulb, a general-purpose technology, applied in the field of LED lighting, can solve the problems of difficult maintenance, high price, and delay in maintenance, and achieve the effect of improving batch production, facilitating industrialization, and reducing production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

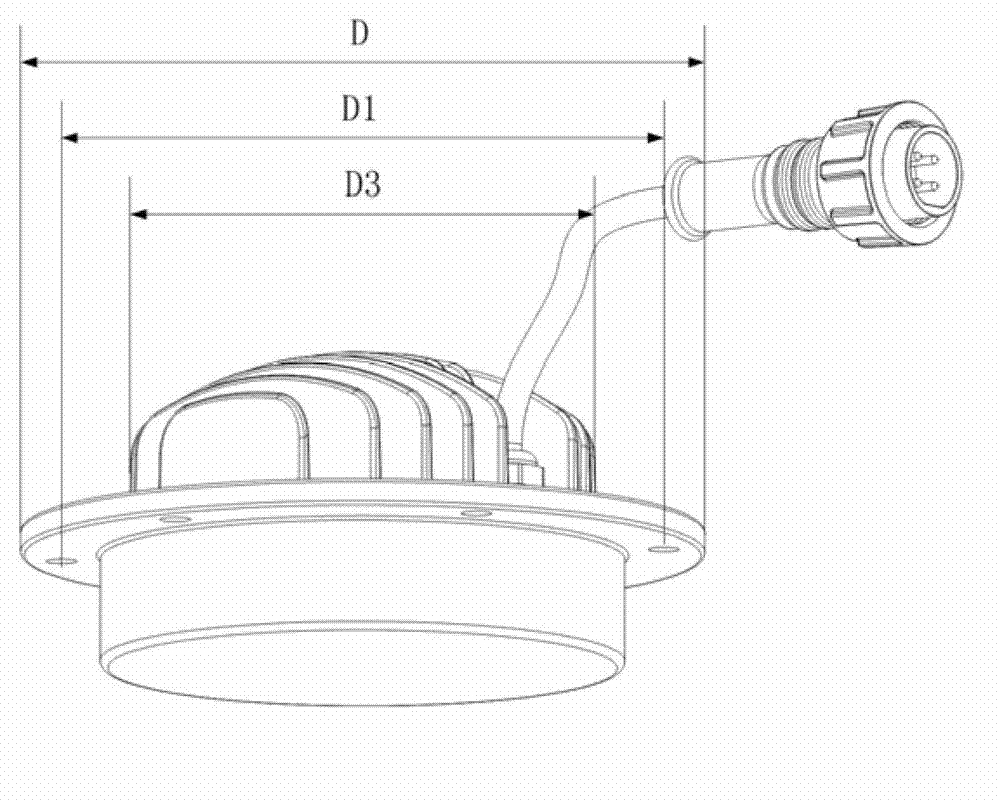

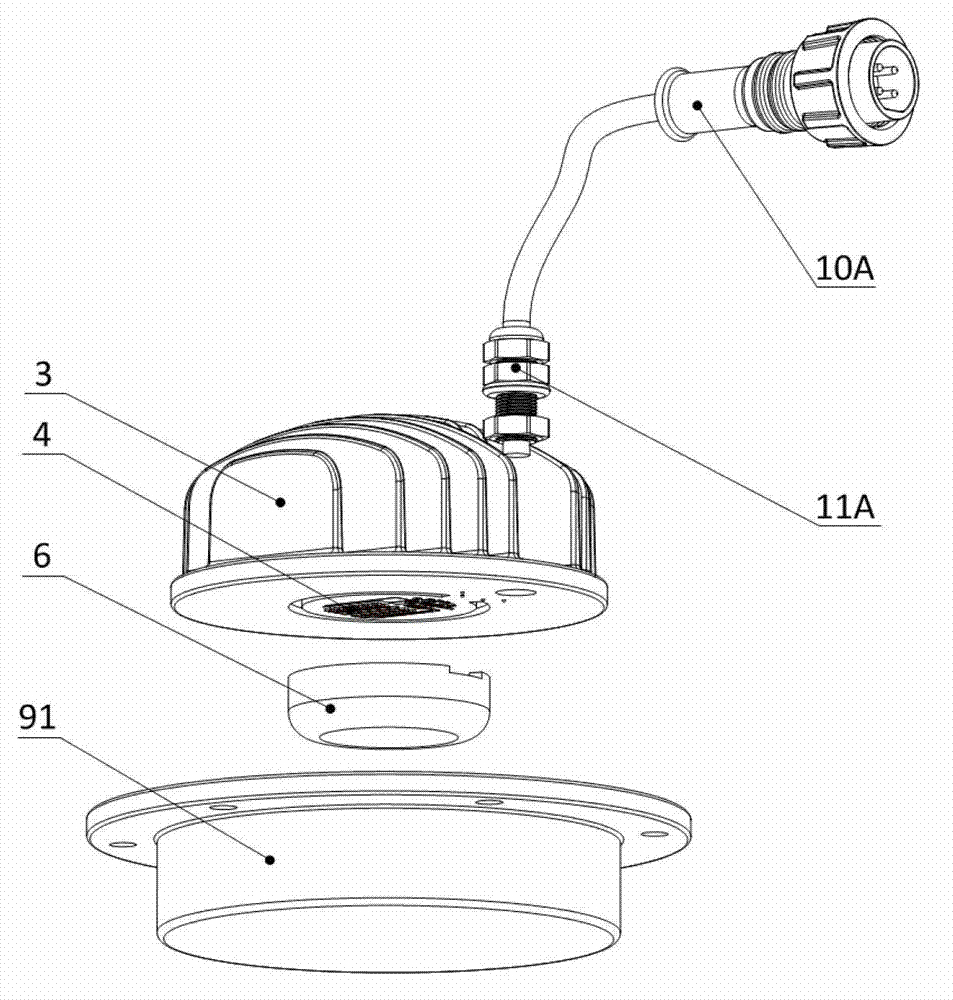

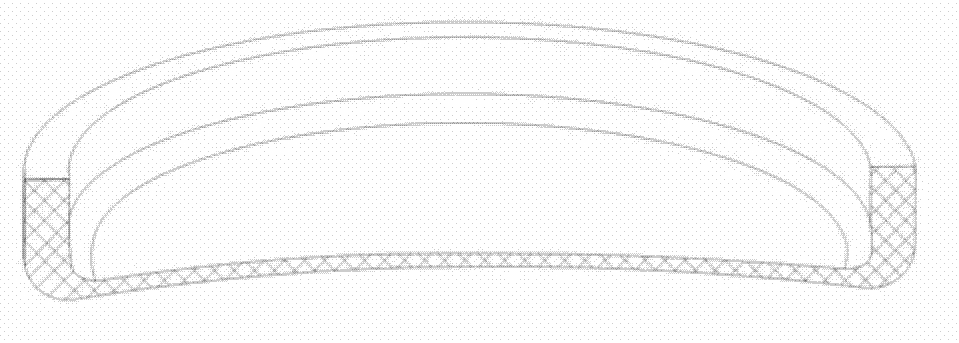

[0022] Example. A general-purpose LED light bulb construction method, by embedding a silver paste printed circuit on a thermally conductive support with a heat sink formed by sintering non-metallic thermally conductive materials, and then welding LED chips (or other related drivers) on the silver paste printed circuit chip components), constitute the LED bulb. The bulb inner cover is fixed on the heat conduction bracket by setting slots, and the LED chip and the driver chip are wrapped in the bulb inner cover. The heat-conducting bracket is also provided with an embedded groove to fix the bulb cover or the lens, and the heat-conducting bracket is fixed in the bulb cover with a mounting flange; the bulb inner cover is a concave inner cover made of elastic material, and the concave inner cover T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com