Micro-pressure multifunctional boiler with high-temperature steam

A high-temperature steam and multi-functional technology, applied in the field of boilers, can solve the problems of increased operation and use risks of pressure boilers, difficulty in meeting smoke and dust emission standards, threats to people's lives and property, etc., and achieves simple structure, labor-saving and clean operation, and complete combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

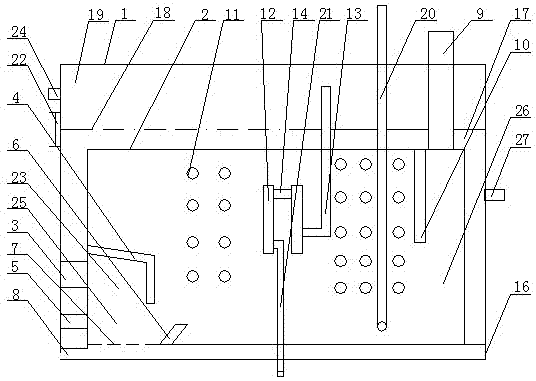

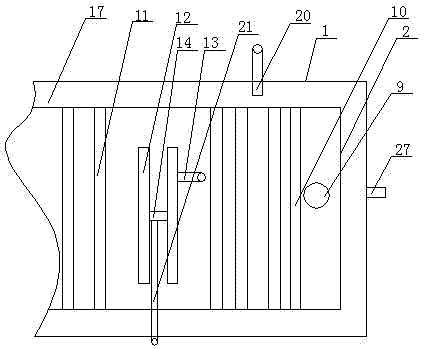

[0016] Such as figure 1 and figure 2 The micro-pressure high-temperature steam multifunctional boiler shown includes a furnace body 1 and a furnace inner tank 2, the cavity formed by the furnace body 1 and the furnace inner tank 2 is a water tank 17, a fuel bin door 3 and an air inlet door 5 All are arranged on the furnace body 1 and communicate with the furnace inner liner 2 respectively, and the setting of the air inlet door increases the air intake, so that the oxygen supply is sufficient when the fuel is burned, and the combustion is complete, and no blower or induced draft fan is needed. A chimney 9 is also arranged on the inner tank, and the chimney 9 leads to the outside of the furnace body. A water inlet pipe 24 is arranged on the furnace body, a water level line 18 is arranged on the upper part of the water tank 17, and a steam heating box is arranged in the inner tank 2 of the furnace body. 12. One end of the steam input pipe 13 of the steam heating box 12 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com