Real-time detection method of soft abrasive flow abrasive group

A technology of real-time detection and detection method, applied in the direction of testing moving fluids/granular solids, etc., can solve the problems of poor rapidity and poor accuracy of detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings.

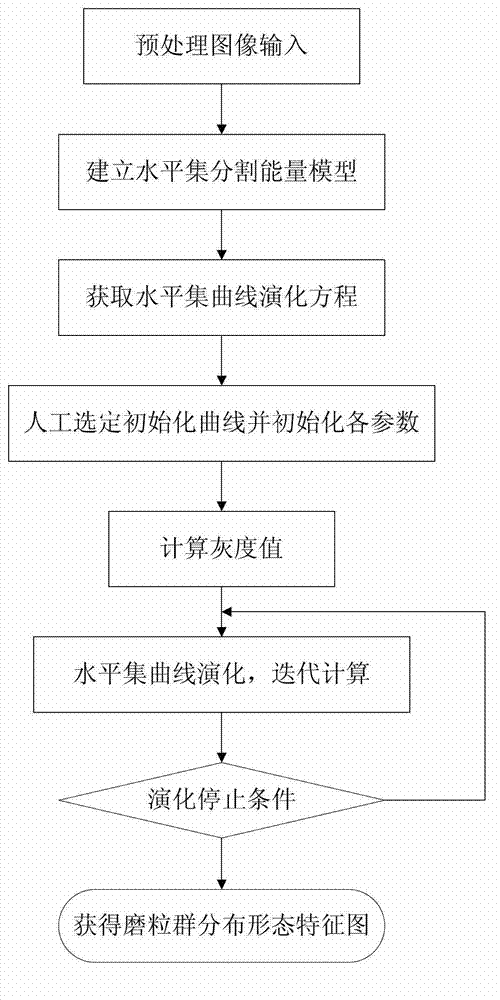

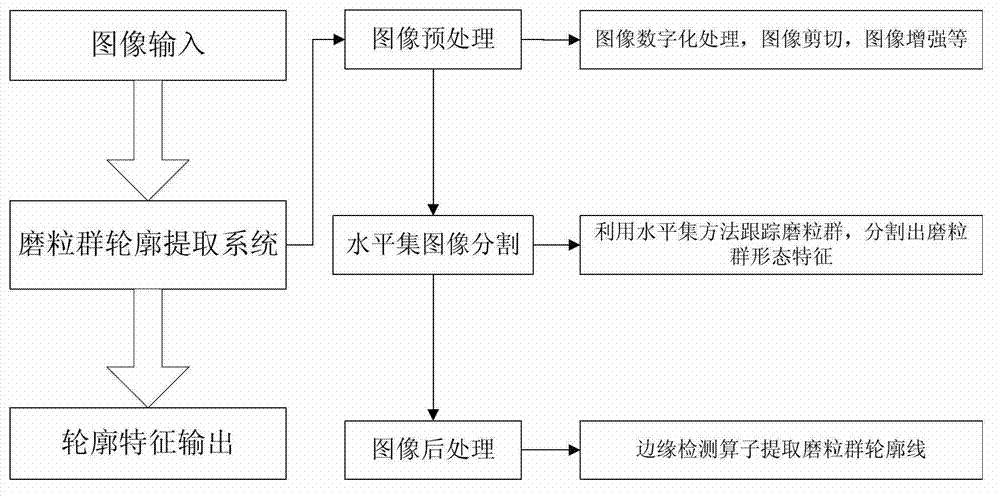

[0056] refer to Figure 1~Figure 5 , a method for real-time detection of abrasive particles in a soft abrasive flow, the detection method comprising the following steps:

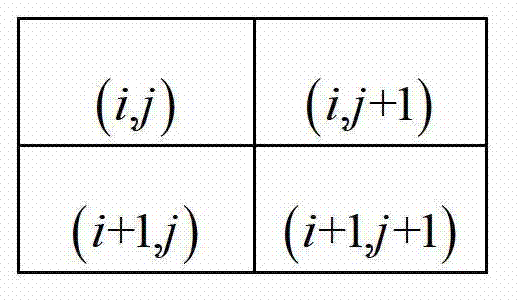

[0057] 1) Let Ω 1 It is a two-dimensional physical space model, the liquid-solid two-phase soft abrasive particle flow is the medium of the space, and the instantaneous interface of the abrasive particle group is the interface. The phase field function φ(x,t) is assumed to be a specific constant at each bulk phase, and to undergo rapid and smooth changes at the interface. The relationship between the two-phase fluid and its interface at time t is defined by the following formula:

[0058]

[0059] Establish the phase field model two-phase interface mixing energy equation:

[0060] W ( φ , ▿ φ ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com