Quality-fluctuation prediction method for multi-procedure processing process

A technology of quality fluctuation and process, applied in instrumentation, adaptive control, control/regulation system, etc., can solve problems such as poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

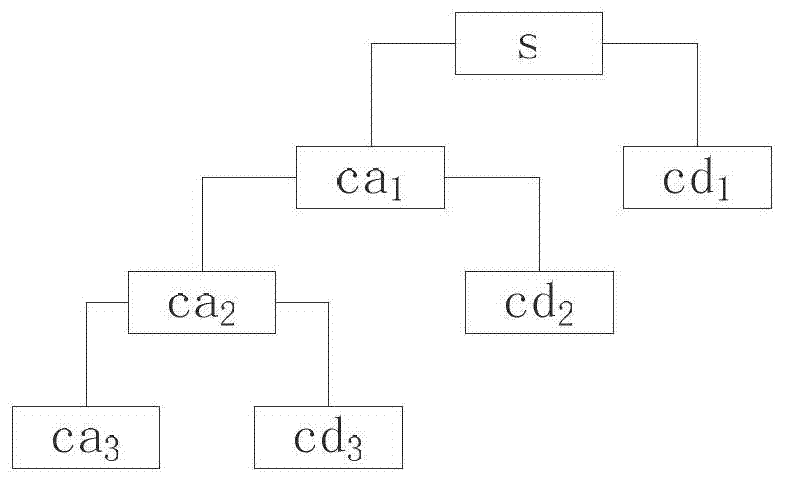

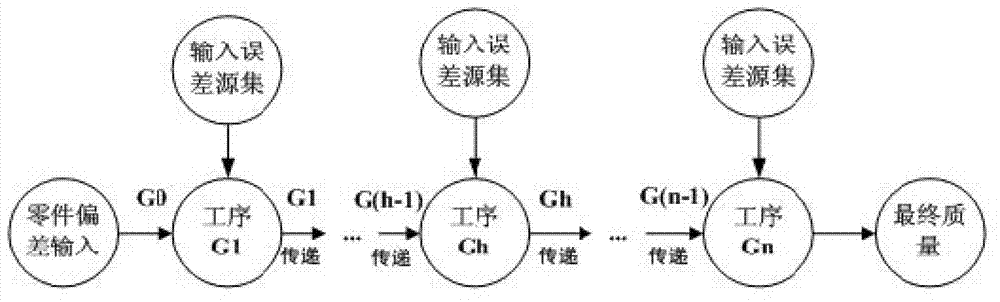

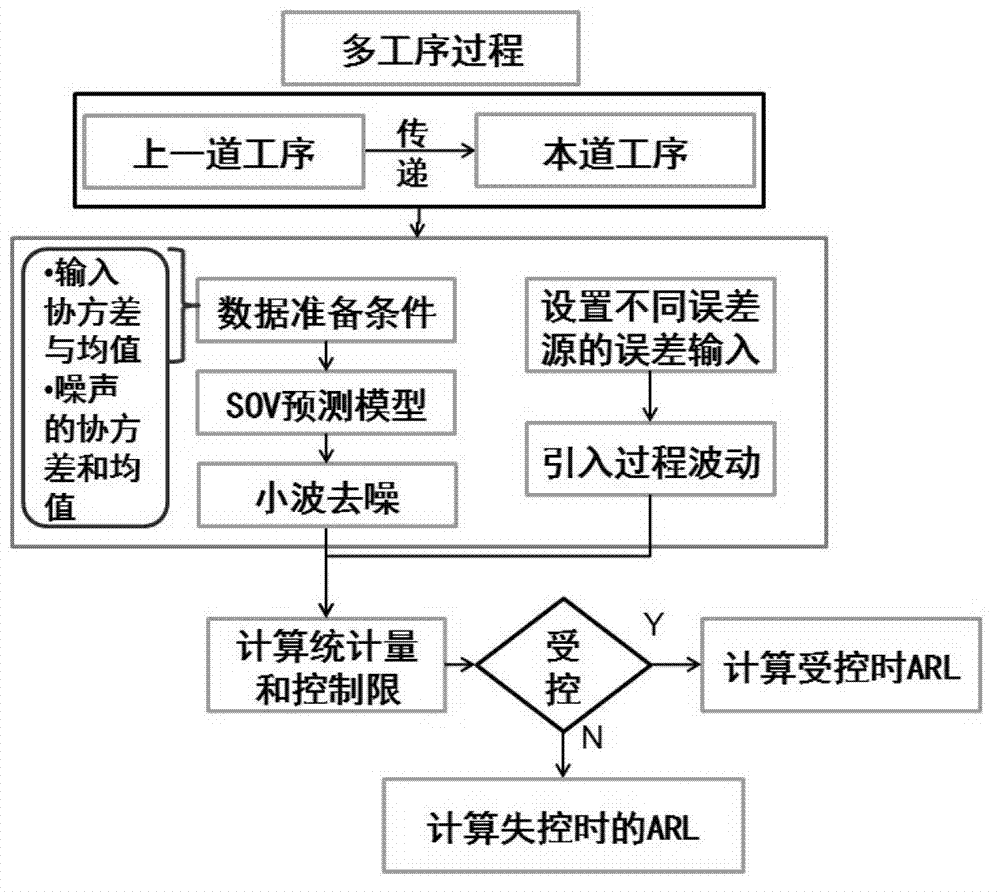

[0044] The following examples refer to Figure 1~6 .

[0045] The machining process of a part is composed of p related key quality characteristics, including various quality characteristics of size, shape and position. These p quality characteristics constitute the quality state set of the part, and they are monitored as the process changes , the monitoring of fluctuations in the machining process of parts can be completed. It is assumed that m times are collected during processing, and the sample size of each collection is n.

[0046] Then X ij =(X ij1 , X ij2 ,...,X ijp ) is a p-dimensional vector, representing the p-dimensional quality characteristic of the jth observation value in the i-th sample, where i=1, 2,..., m, j=1, 2,..., n. x ij The first component is obtained, which represents the first quality characteristic, 1=1, 2,...,p. Let the p indicators obey the p-dimensional normal distribution N p [μ, ∑], the mean vector μ and covariance ∑ are unknown, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com