Optical fiber type anti-oil spillage control system and control method

A technology of control system and optical fiber, applied in the direction of control/adjustment system, liquid level control, non-electric variable control, etc., can solve the lack of low-cost, easy-to-operate and high-stability anti-spill control system, maintenance personnel technical ability requirements Higher, increased use costs and other issues, to achieve the effect of easy installation, commissioning and maintenance, improved safety, and reduced labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

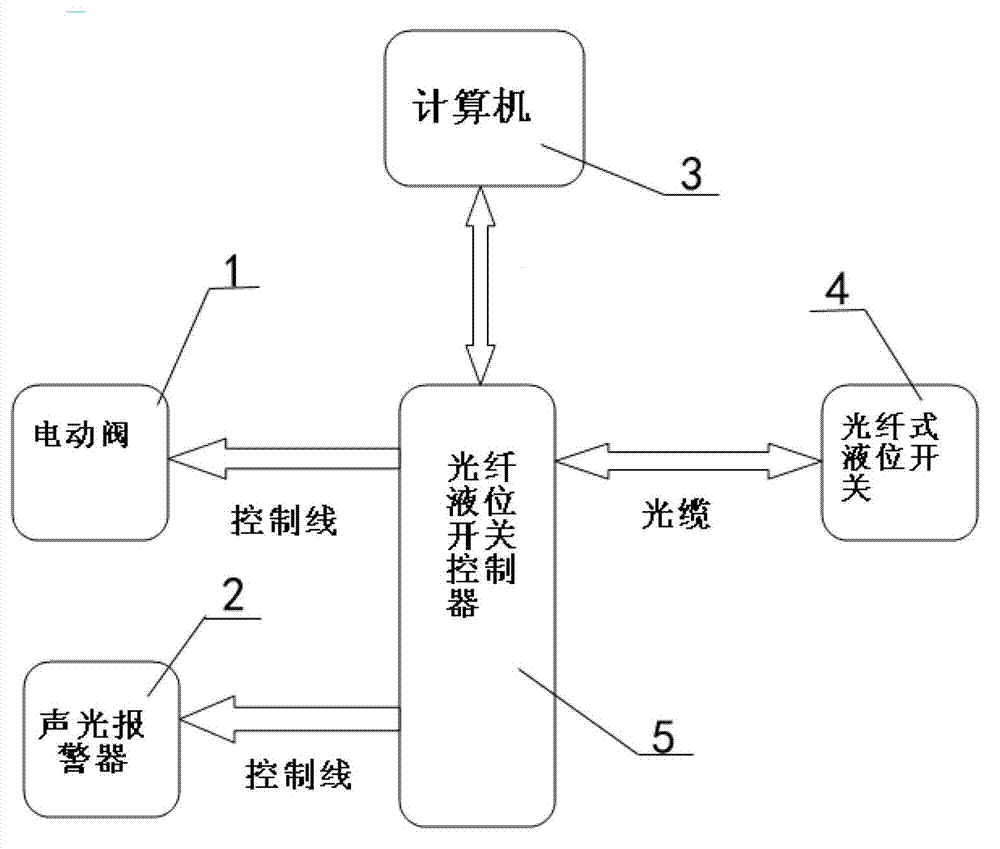

[0024] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 5 , Figure 7 As shown, a fiber optic oil spill prevention control system includes an electric valve 1 connected to the oil supply system, an audible and visual alarm 2, a computer 3, and a fiber optic liquid level for detecting the oil spill level in the oil filling container Switch 4, an optical fiber controller 5 for controlling the optical fiber liquid level switch, the optical fiber liquid level switch 4 is connected to the optical fiber liquid level switch controller 5 through an optical cable, and the sound and light alarm 2 is connected to the optical fiber liquid level switch. The level switch controller 5 is connected through a signal line; the electric valve 1 is connected with the optical fiber liquid level switch controller 5 through a signal line.

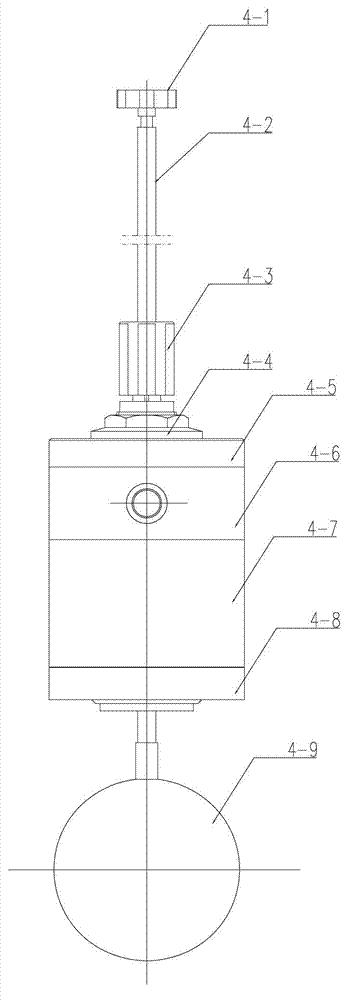

[0025] The optical fiber liquid level switch 4 includes an isolation box 4-7, a floating ball 4-9, a floating ball connecting rod 4-2, and an optic...

Embodiment 2

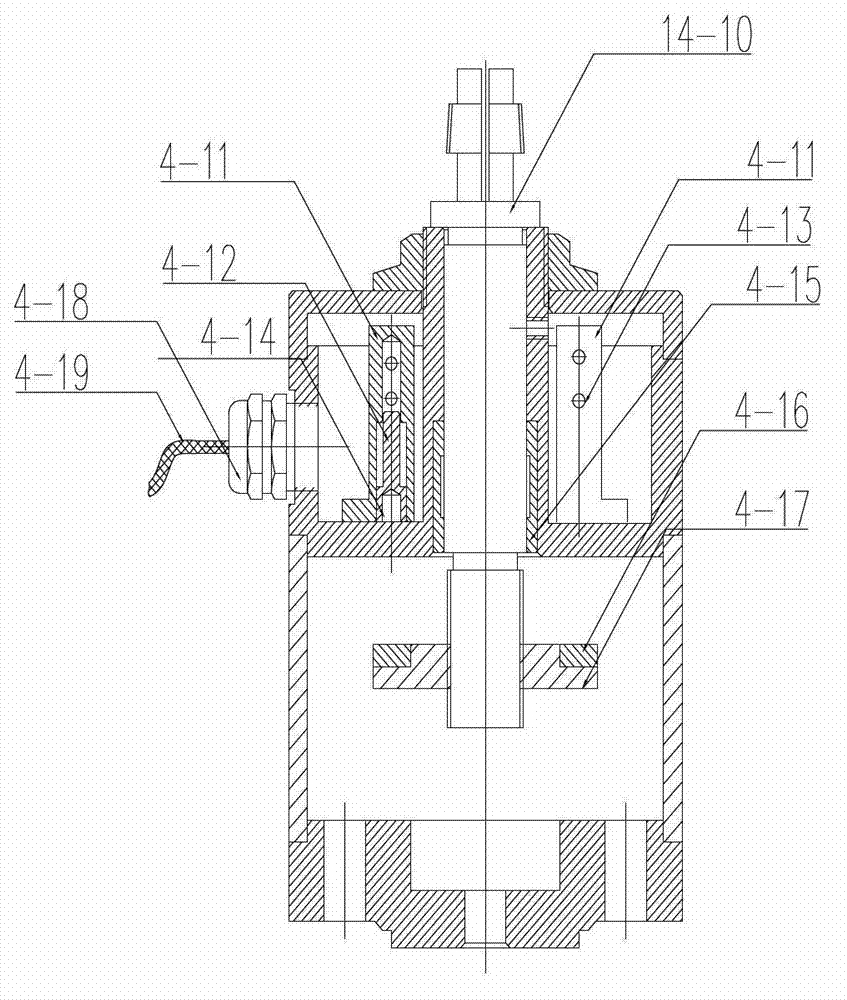

[0029] Embodiment 2: as Figure 4 , Figure 6 As shown, it is the same as Embodiment 1, except that the optical fiber liquid level switch 4 includes an isolation box 4-7, a float 4-9, a float connecting rod 4-2, and the side wall of the isolation box 7 There is an optical cable clamping joint 4-18 on it, and the floating ball connecting rod 4-2 is set through the isolation box 4-7 through the guide column 4-10, and is connected with the isolation box 4-7 through the lock nut 4-3. Fixed, the float 4-9 is arranged at the end of the float 4-2 below the isolation box 4-7; the isolation box 4-7 is divided into an upper cavity and a lower cavity through a partition; in the upper cavity A collimator bracket 4-11 is provided, and the collimator bracket 4-11 is provided with a collimator 4-13 and a light blocking axis 4-12 for blocking the output parallel light of the collimator, and the light blocking axis 4-12 is a magnetic material, and the collimator 4-13 is arranged below the li...

Embodiment 3

[0031] Embodiment 3: The present invention also provides a control method of a fiber optic liquid level switch controller. When the oil overflow level in the oil filling container reaches a set value, the fiber optic liquid level switch 4 arranged in the oil filling container sends out an early warning and an alarm Optical fiber signal, and transmit the signal to the optical fiber liquid level switch controller 5 through the optical cable, the optical fiber liquid level switch controller 5 converts the early warning and alarm optical fiber signal into the early warning and alarm electrical signal, and sends out the early warning and alarm signal, and closes the The electric valve 1 stops filling the oiling container, and the optical fiber liquid level switch controller 5 simultaneously transmits the early warning and alarm to the computer 3 through the RS485 signal converter 5-16 of the optical fiber liquid level switch controller 5 for oil spilling. Early warning, alarm.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com