IGBT (insulated gate bipolar translator) module packaging process and IGBT module with bidirectional heat radiation

A two-way heat dissipation and module packaging technology, which is applied in the IGBT module packaging process and the field of IGBT modules with two-way heat dissipation, can solve problems such as temperature rise, high-power IGBT chip damage, and poor heat dissipation, so as to improve heat dissipation and chip efficiency. , The effect of improving the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

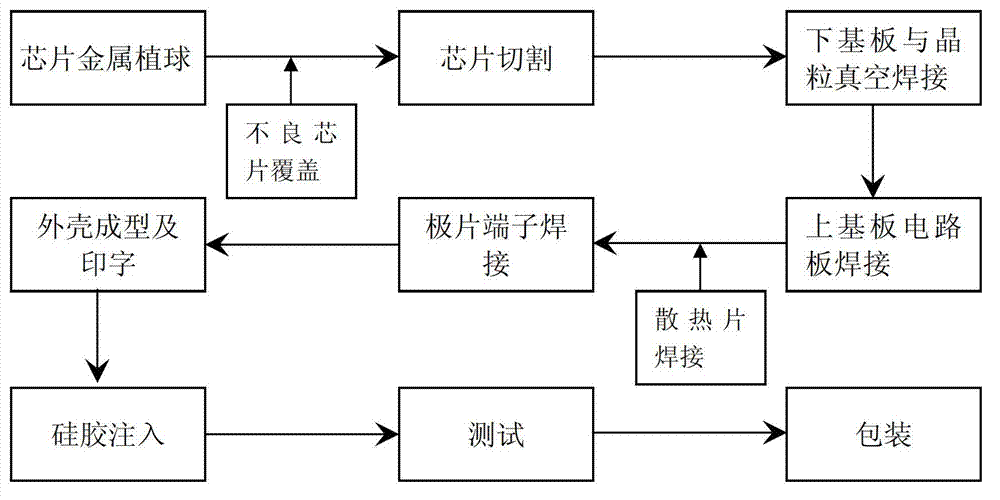

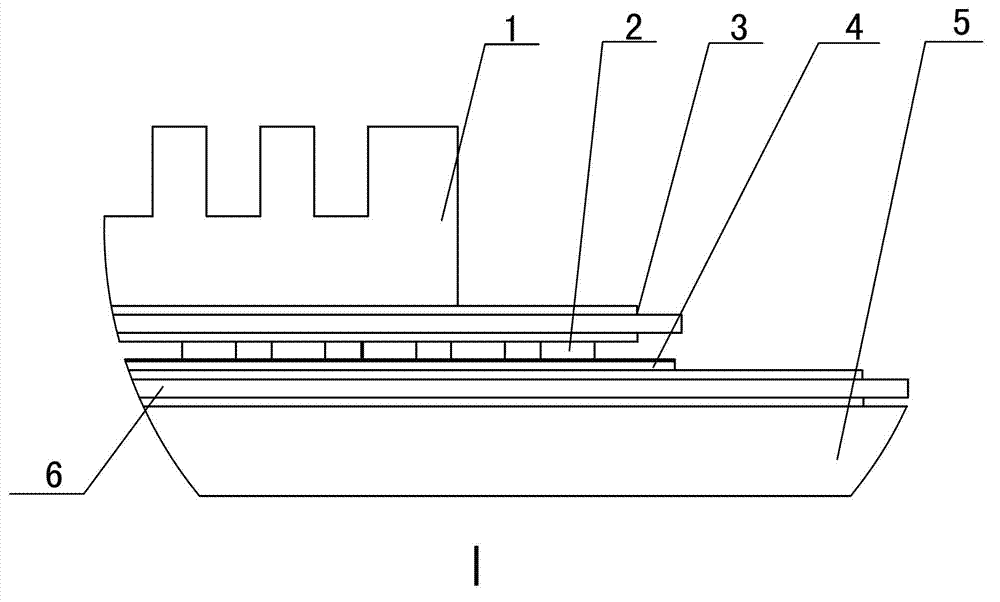

[0031] Figure 1-3 , 5-8 is the best embodiment of the IGBT module packaging process and the IGBT module of the present invention, below in conjunction with the attached Figure 1-8 The present invention will be further described.

[0032] Refer to attached Figure 1-8 :

[0033] The IGBT module of the present invention is composed of an upper heat sink 1, a metal ball 2, an upper substrate 3, a chip 4, a lower heat dissipation plate 5 and a lower substrate 6, and a metal ball 2 is implanted on the chip 4, and the metal ball 2 directly connects the chip 4 with the The upper substrate 3 with lines is connected, and a heat dissipation device is arranged above the metal ball 2 . The heat dissipation device includes an upper substrate 3 and an upper heat sink 1 above it. Both the upper substrate 3 and the lower substrate 6 are ceramic copper clad laminates. The upper heat sink 1 is fin-shaped.

[0034] Refer to attached Figure 4 and Figure 5 :

[0035] Figure 4 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com