Red LED packaging method

An LED packaging, red light technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as difficulty in ensuring product quality in mass production, low red light color rendering index, and large color area dispersion, and achieves a wide range of benefits. Promote application, ensure product quality, and achieve high comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

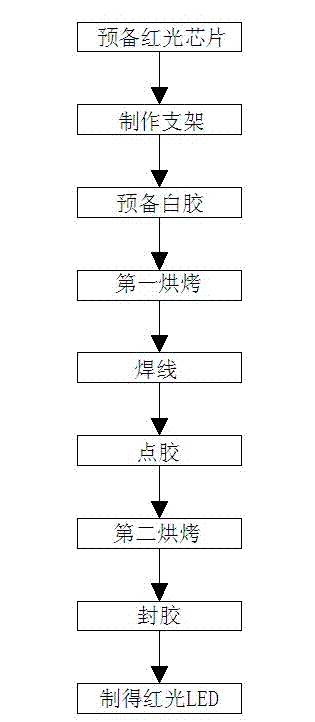

[0019] Example: see figure 1 , the present embodiment provides a red light LED packaging method, which includes the following steps: (1) preparing a red light chip; (2) making a bracket, and a bowl cup for placing the red light chip is arranged on the top of the bracket; 3) Prepare white glue, dot the white glue on the bottom of the bowl, then place the red light chip on the white glue, and then fix it on the bowl; (4) First bake, fix the red light chip Move the bracket to the oven. The temperature of the oven is set at 140-160°C, and the baking time is set at 1.5-2.5 hours; (5) Welding wire: prepare gold wire, and weld one end of the gold wire to the On the red light chip, the other end is welded on the bracket to realize the connection between the red light chip and the bracket; (6) dispensing glue, preparing silver light glue, and pouring the silver light glue into the bowl cup of the bracket until it is clicked The glue surface of the silver glue in the bowl is flush with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com