Composite body

A composite and integral technology, applied in the field of composites, can solve the problems of low bonding strength and achieve the effect of high bonding strength and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

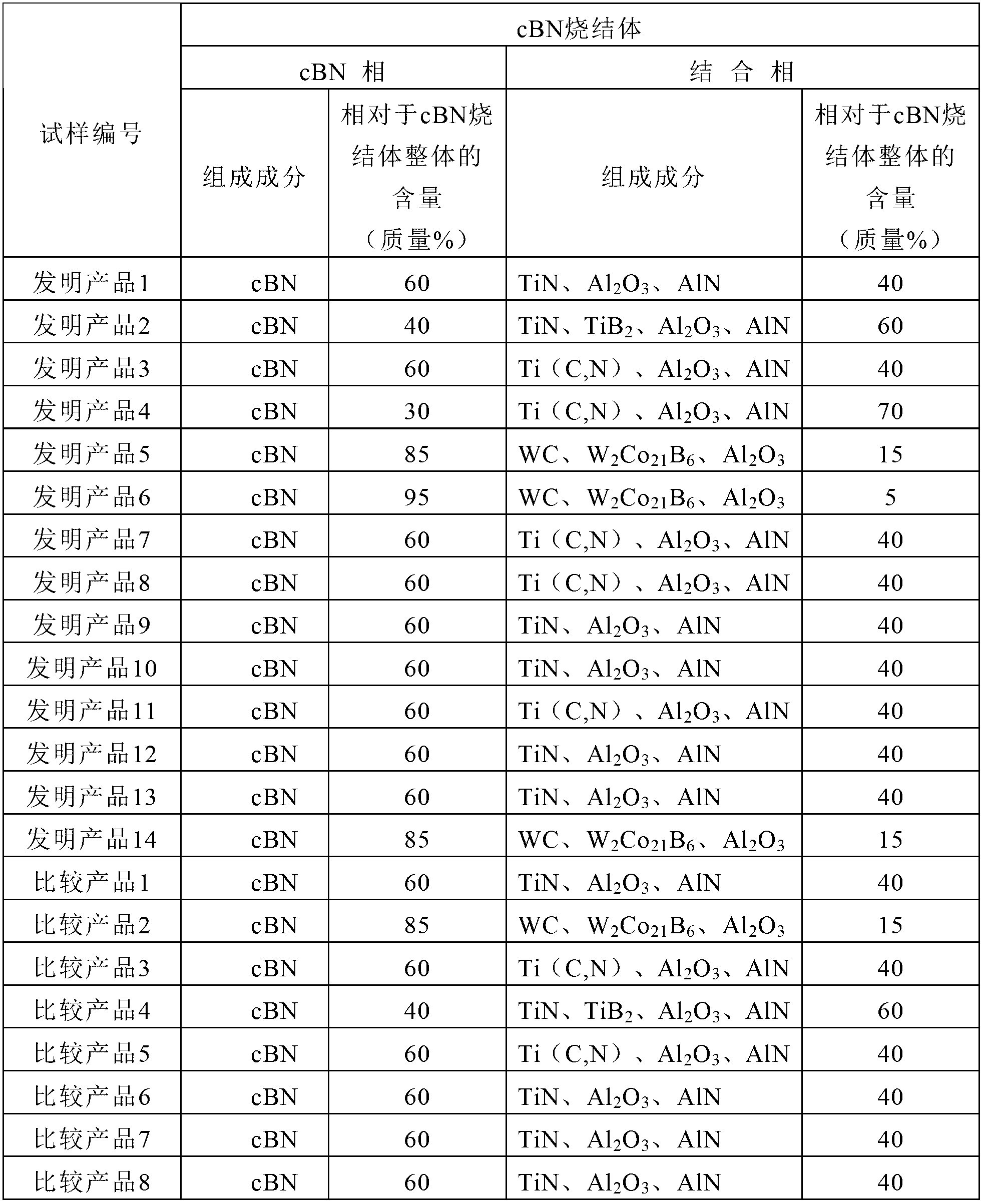

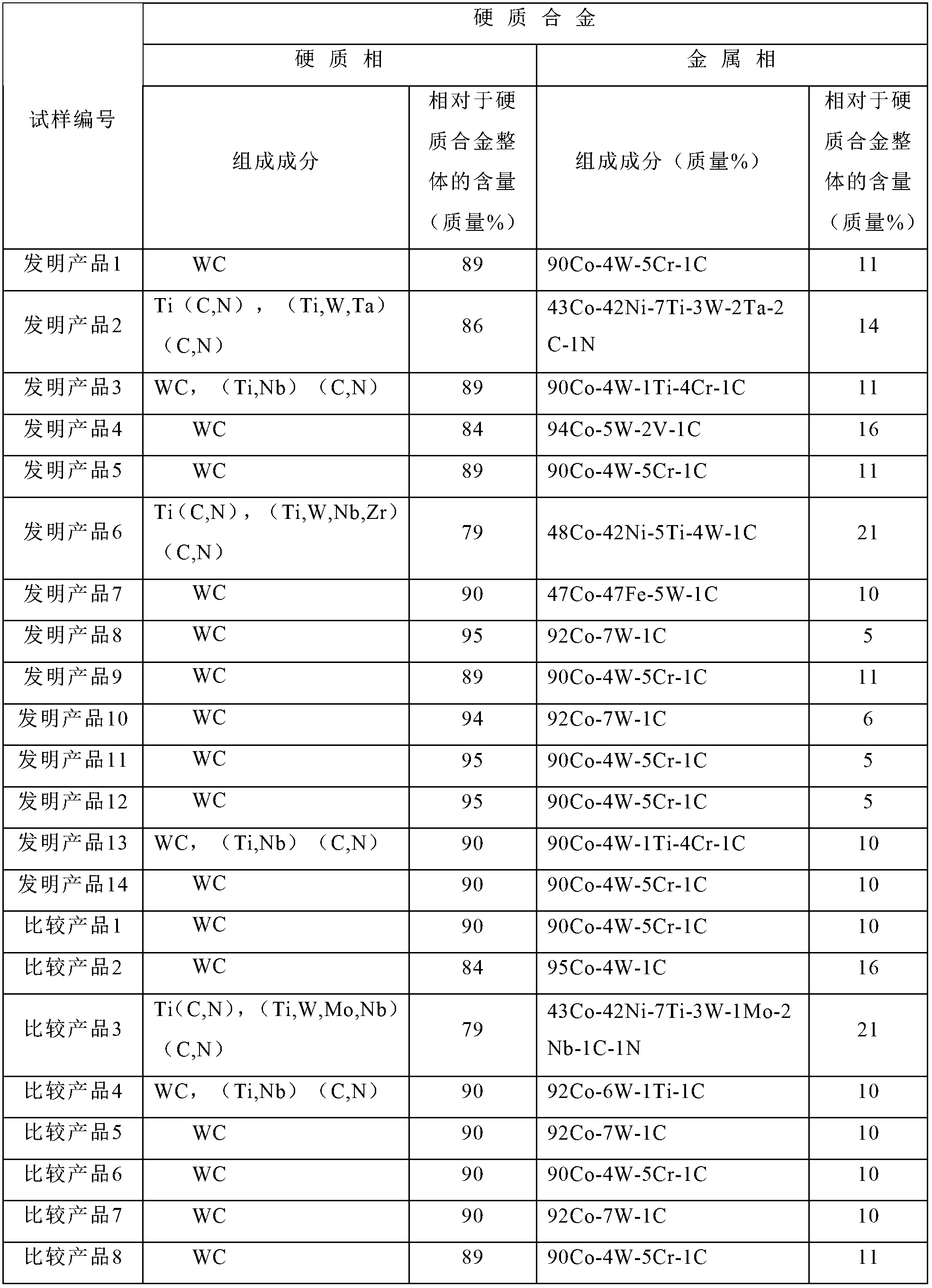

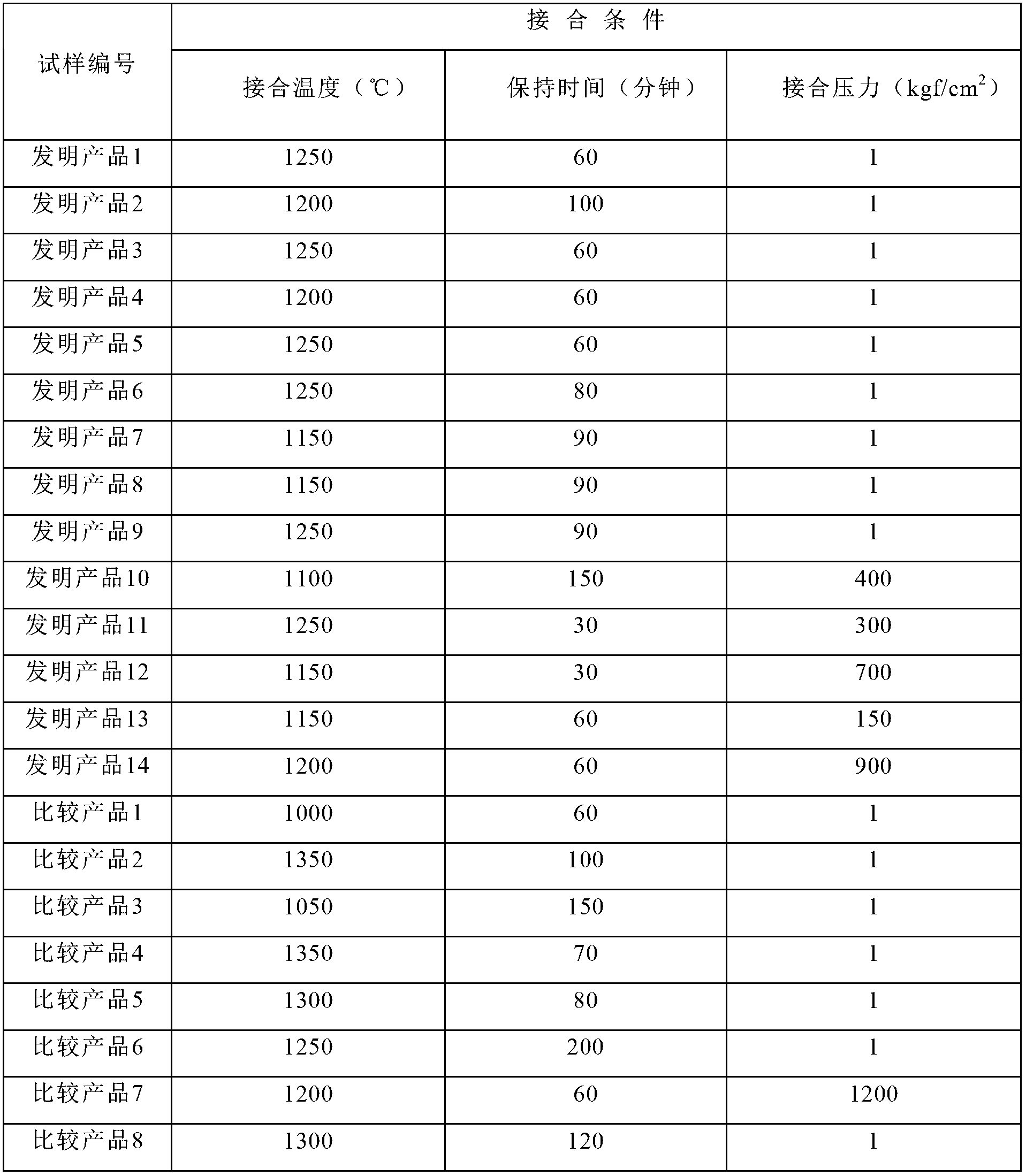

[0020] A disc-shaped cBN sintered body having a diameter of 30 mm and a thickness of 1.5 mm having the composition shown in Table 1 and a disc-shaped cemented carbide having a diameter of 30 mm and a thickness of 3.0 mm having the composition shown in Table 2 were prepared. Use diamond abrasive grains, etc., to mirror-polish the joint surfaces of all samples, and then place them in acetone for 10 minutes of ultrasonic cleaning. Then, the joint surface of the cBN sintered body and the cemented carbide joint surface were overlapped by a hot press device, and the load shown in Table 3 was applied, and the temperature was raised from room temperature to the joining temperature shown in Table 3 in a vacuum, Then, the bonding pressure, bonding temperature, and holding time shown in Table 3 were maintained, and then cooled. After cooling, the applied load was removed to obtain a composite body in which cBN sintered body and cemented carbide were joined.

[0021] Table 1

[0022] ...

Embodiment 2

[0032] Prepare a binding phase of cBN-40 mass % with a composition of 60 mass % (the composition of the binding phase: TiN, Al 2 o 3 , AlN) disc-shaped cBN sintered body with a diameter of 30mm and a thickness of 1.5mm, and a metal phase with a composition of 89% by mass of WC-11% by mass (composition of the metal phase: 95% by mass of Co-4% by mass W-1% by mass C) disc-shaped cemented carbide having a diameter of 30 mm and a thickness of 3.0 mm. Using diamond abrasive grains, etc., the cBN sintered body and the cemented carbide joint surface were mirror-polished, and then placed in acetone for 10 minutes of ultrasonic cleaning. Then, using a hot pressing device, the bonding surface of the cBN sintered body and the bonding surface of the cemented carbide overlapped, and in order not to deviate the position of the sample, a 1kgf / cm 2 While increasing the temperature from room temperature to 1250° C. in a vacuum while applying a pressure load, cooling was performed after maint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com