Ag@Ag2O microcrystals of photocatalytic material with specific patterns and high surface activity and preparation method thereof

A photocatalytic material and composite photocatalytic technology, which is applied in the field of visible light-responsive micro-nano photocatalytic powder material synthesis, and can solve the problems of high photogenerated carrier recombination rate, low photocatalytic efficiency, and lack of controllable morphology photocatalytic ability. , to achieve the effect of simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

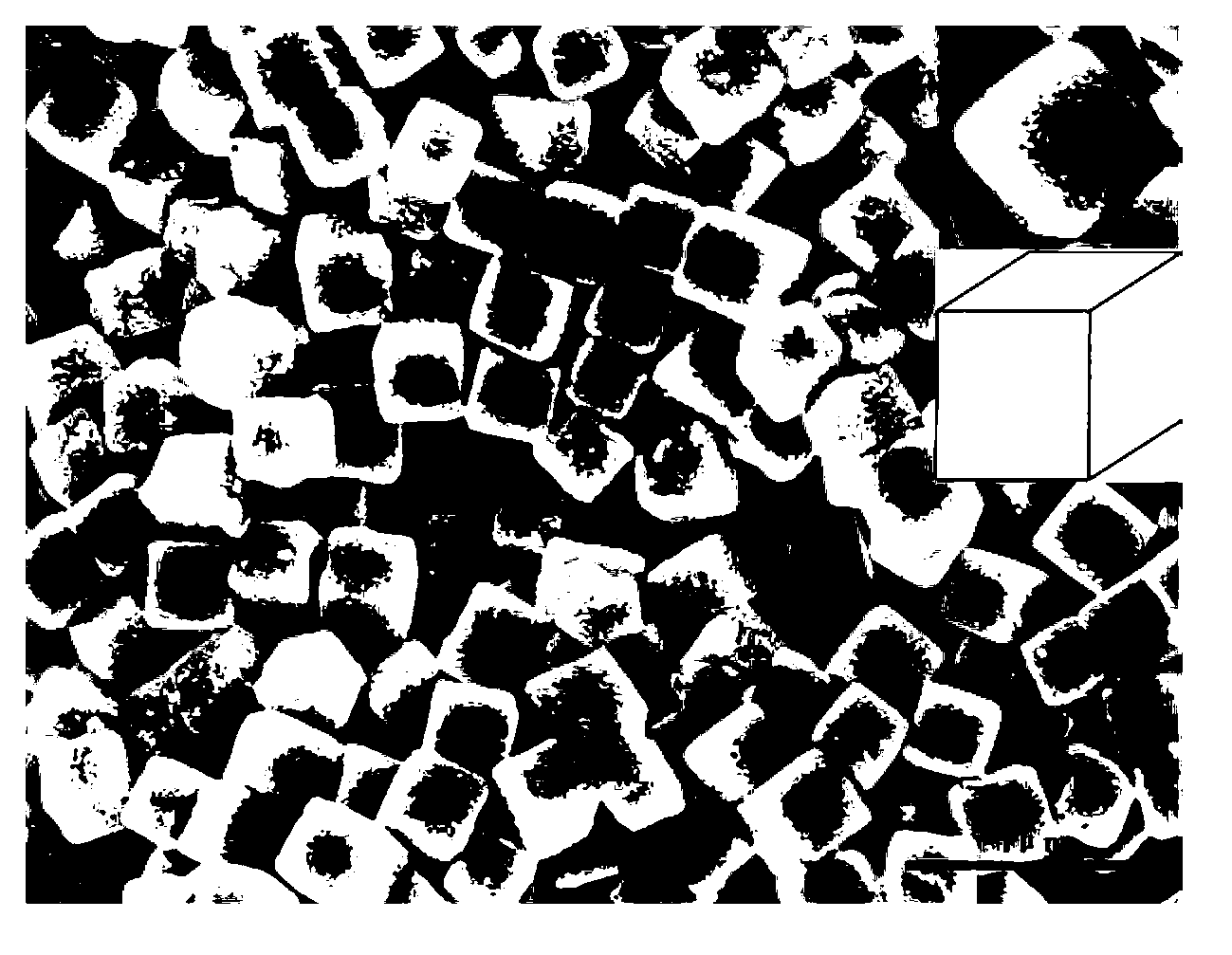

[0048] Add 5ml of 0.01M ammonium nitrate solution to 2.5ml of 0.01M silver nitrate solution, stir for 10 minutes, then add 0.25ml of 2M sodium hydroxide solution, and continue stirring for 10 minutes. The obtained sample was centrifuged with a centrifuge at 5000 rpm, and the obtained dark brown precipitate was washed 3 times with deionized water and ethanol. Dry at 60 for 12 hours; get cubic Ag 2 O, the side length of the cube is 0.5 μm. figure 1 SEM images of the obtained samples. Take 0.2 g of the obtained sample, add it to 100 ml of 20 mg / L methyl orange solution, and irradiate it under visible light for 10 minutes to obtain a black sample, filter it with suction, wash it three times with deionized water and ethanol, and dry it at 60°C for 12 Hour. This gives the cubic AgAg 2 O structure photocatalytic material, the size of the deposited silver is between 20-30nm. Take the cube AgAg 2 O sample 0.1g, add in the 20mg / L methyl orange solution of 100ml, irradiate under vi...

Embodiment 2

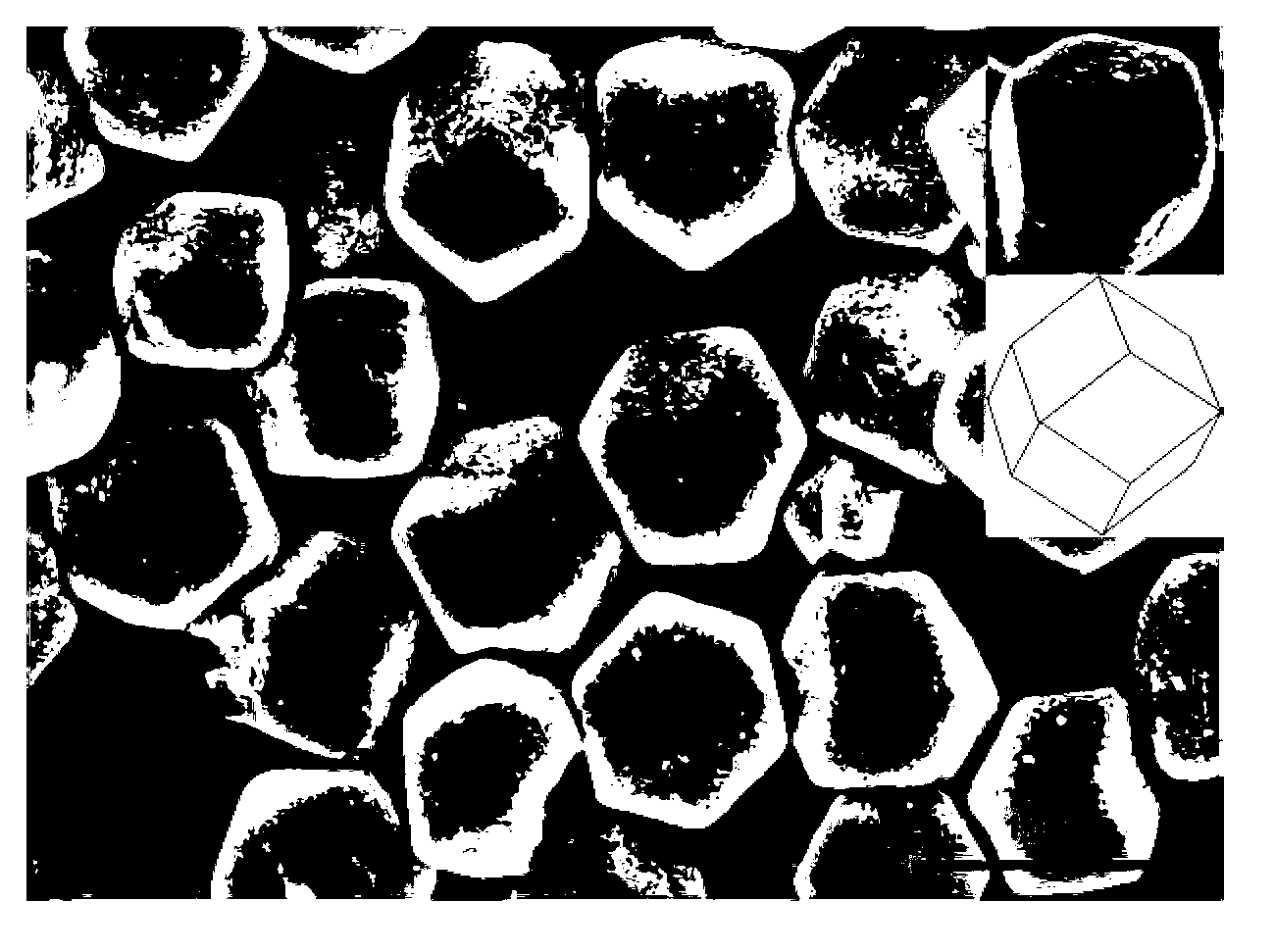

[0050] Add 5ml of 0.03M ammonium acetate solution to 2.5ml of 0.03M silver nitrate solution, stir for 10 minutes, then add 0.25ml of 2M sodium hydroxide solution, and continue stirring for 10 minutes. The obtained samples were centrifuged at 5000 rpm and washed 3 times with deionized water and ethanol. Dry at 60°C for 12 hours. Ag of the obtained rhombohedral dodecahedron 2 O. The rhombic dodecahedron has a size of 0.7 μm. figure 2 SEM images of the obtained samples. Take 0.2 g of the obtained sample, add it to 100 ml of 20 mg / L methyl orange solution, and irradiate it under visible light for 10 minutes to obtain a test sample, filter it with suction, wash it three times with deionized water and ethanol, and dry it at 60°C 12 hours. This gives the rhombohedral AgAg 2 O structure photocatalytic material, the size of the deposited silver is between 20-30nm. Rhombic dodecahedral AgAg 2 O sample 0.1g, add in the 20mg / L methyl orange solution of 100ml, irradiate under visi...

Embodiment 3

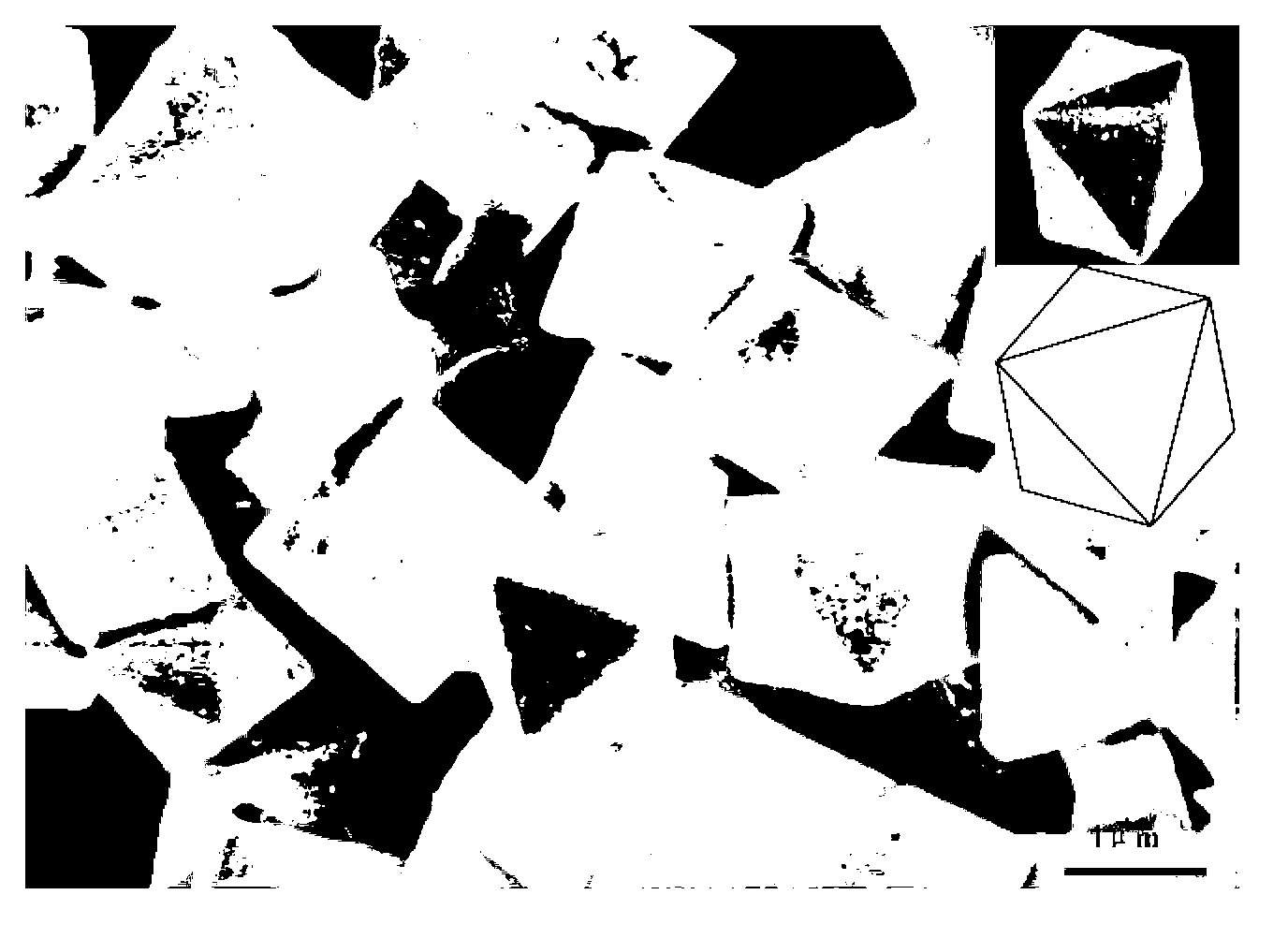

[0052] Add 5ml of 0.5M ammonia solution to 2.5ml of 0.5M silver nitrate solution, stir for 10 minutes, then add 0.25ml of 2M sodium hydroxide solution, and continue stirring for 10 minutes. The obtained samples were centrifuged at 5000 rpm and washed 3 times with deionized water and ethanol. Dry at 60°C for 12 hours. The obtained octahedral Ag 2 O. The size of the octahedron is 2 μm. image 3 SEM images of the obtained samples. Take 0.2 g of the obtained sample, add it to 100 ml of 20 mg / L methyl orange solution, and irradiate it under visible light for 10 minutes to obtain a test sample, filter it with suction, wash it three times with deionized water and ethanol, and dry it at 60°C 12 hours. This gives the octahedral AgAg 2 O structure photocatalytic material, the size of the deposited silver is between 20-30nm. Take octahedral AgAg 2 O sample 0.1g, add in the 20mg / L methyl orange solution of 100ml, irradiate under visible light, measure its degradation efficiency wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com