Method for preparing AgX@g-C3N4 composite photocatalytic material

A technology of agxg-c3n4 and g-c3n4 is applied in the field of preparing AgXg-C3N4 composite photocatalytic materials, which can solve problems such as unreported, and achieve the effect of simple and easy-to-control reaction process, low cost and high visible light catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

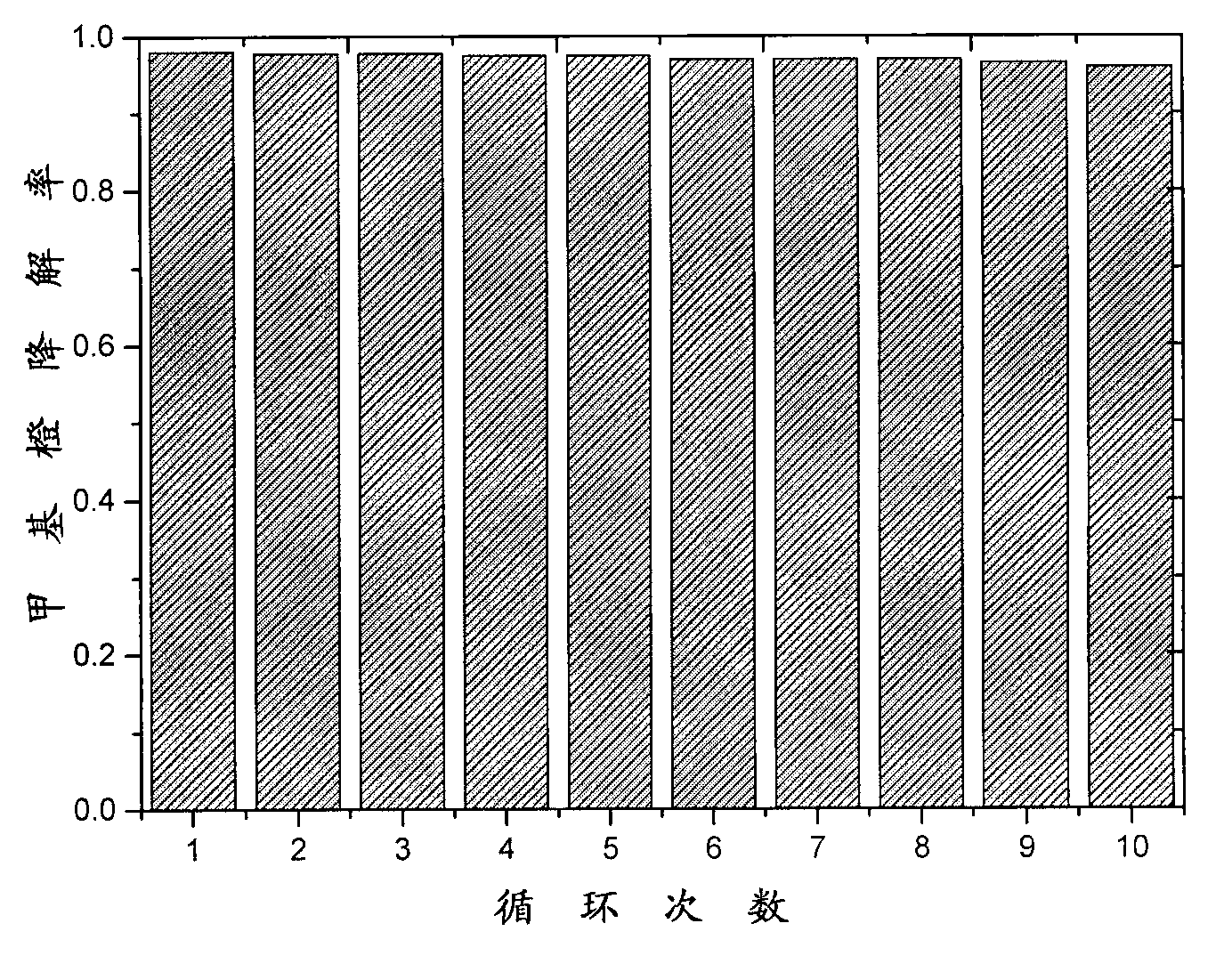

[0017] Weigh 0.026g of g-C 3 N 4 powder, added to 35ml of deionized water, ultrasonicated for 30 minutes, then weighed 0.595g of silver nitrate and dissolved in the above dispersion, and kept stirring for 4 hours. Then, 35ml of KCl aqueous solution with a concentration of 0.1M was slowly added dropwise to the above mixed solution, and the reaction was continued for 24 hours, and the product was washed and dried to obtain the corresponding AgClg-C 3 N 4 Composite photocatalytic materials. Test the AgClg-C 3 N 4 -5% for the photocatalytic properties of methyl orange, as figure 1 shown.

Embodiment 2

[0019] Weigh 0.056g of g-C 3 N 4 powder, added to 9ml of deionized water, ultrasonicated for 1 hour, then weighed 0.459g of silver nitrate and dissolved in the above dispersion, and kept stirring for 4 hours. Then, 9 ml of KBr aqueous solution with a concentration of 0.3 M was slowly added dropwise to the above mixed solution, and the reaction was continued for 18 hours, and the product was washed and dried to obtain the corresponding AgBrg-C 3 N 4 -10% composite photocatalytic material.

Embodiment 3

[0021] Weigh 0.129g of g-C 3 N 4 powder, added to 22ml of deionized water, ultrasonicated for 1 hour, then weighed 0.374g of silver nitrate and dissolved in the above dispersion, and kept stirring for 3 hours. Then, 22ml of KI aqueous solution with a concentration of 0.1M was slowly added dropwise to the above mixed solution, and the reaction was continued for 24 hours, and the product was washed and dried to obtain the corresponding AgIg-C 3 N 4 -20% composite photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com