Laser direct writing machining system by using liquid crystal light valve reshaping

A technology of liquid crystal light valve and laser direct writing, applied in laser welding equipment, metal processing equipment, optics, etc., can solve the problems of low efficiency and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

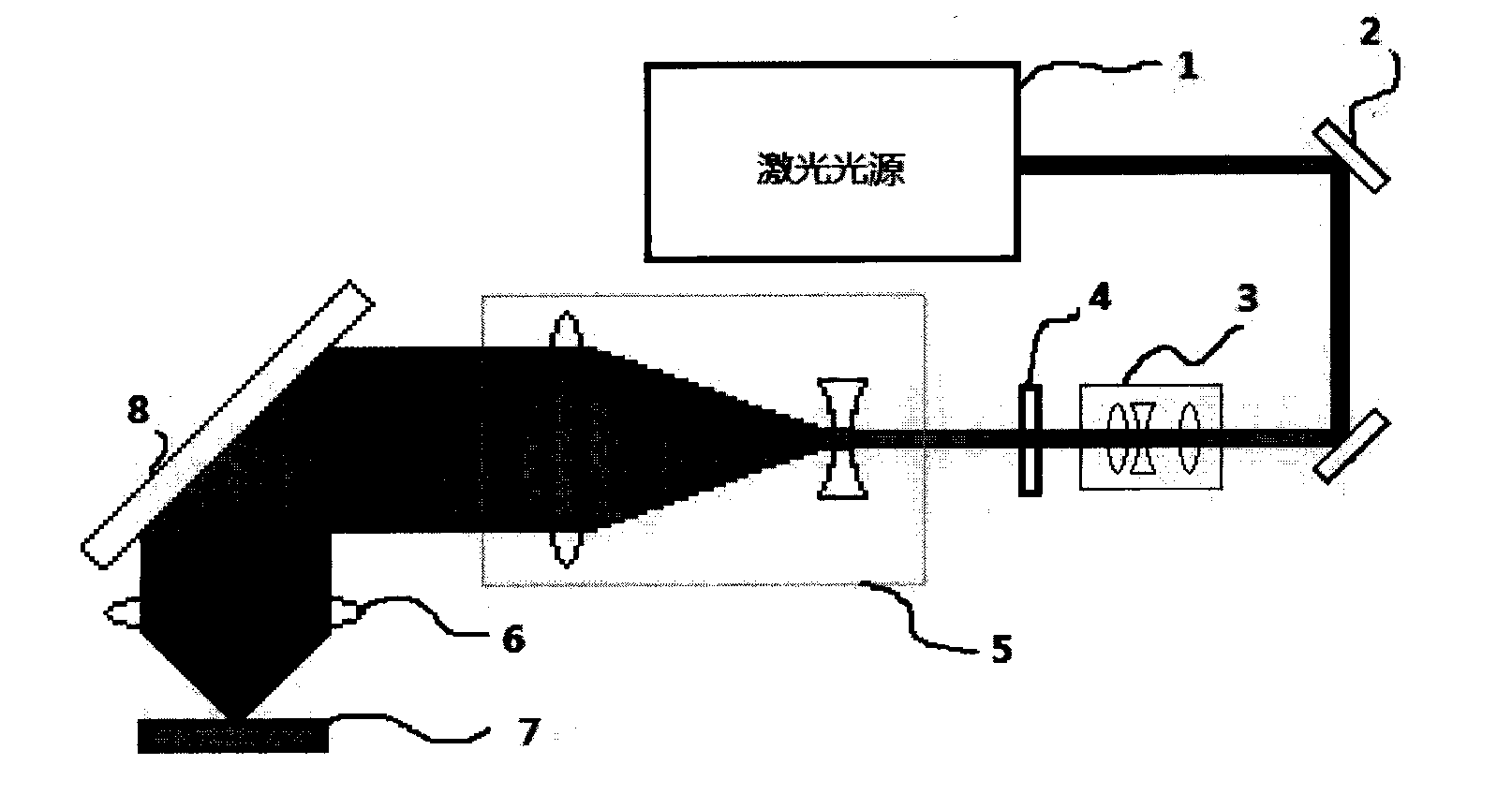

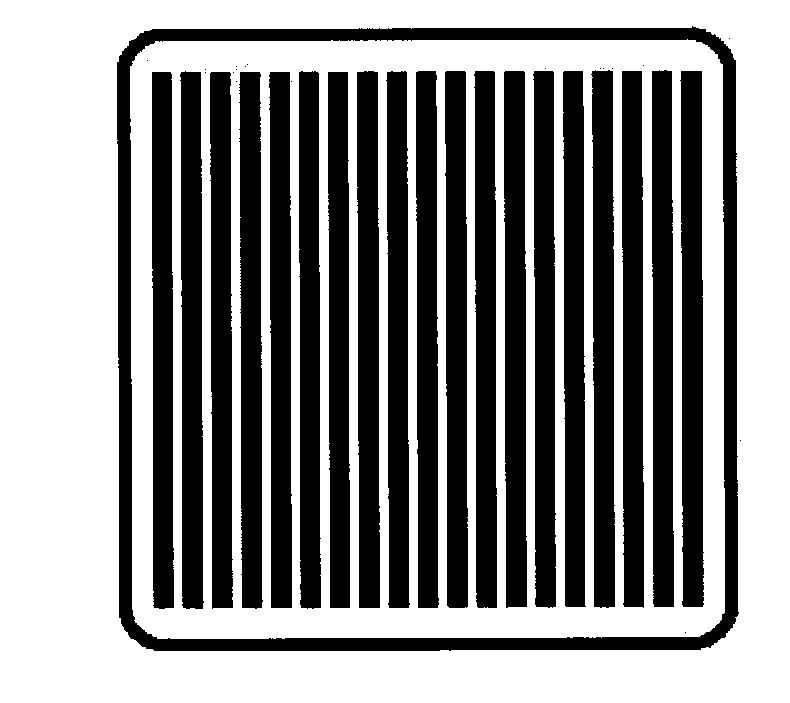

[0026] refer to figure 1 , to fabricate a laser direct writing device that includes real-time shaping of liquid crystal light valves. The laser light source 1 selected by this device is a picosecond pulse laser produced by Coherent Company, with a pulse width of 15 ps and a pulse repetition frequency of 15 kHz. The output formed by the laser light source 1 is deflected by the mirror group 2. The mirror group 2 includes 3 mirrors, which deflect the laser light emitted by the laser light source 1 to the required position and angle, and pass the pre-shaping from the center. Lens group 3. The front shaping lens group 3 includes two convex lenses and one concave lens, which expands the laser beam emitted by the laser light source 1 to a diameter of 15mm. The laser beam with a diameter of 15 mm emitted from the front shaping lens group 3 is irradiated on the liquid crystal light valve 4 . The liquid crystal light valve 4 is a LCX016AL-6 transmissive liquid crystal light valve pro...

Embodiment 2

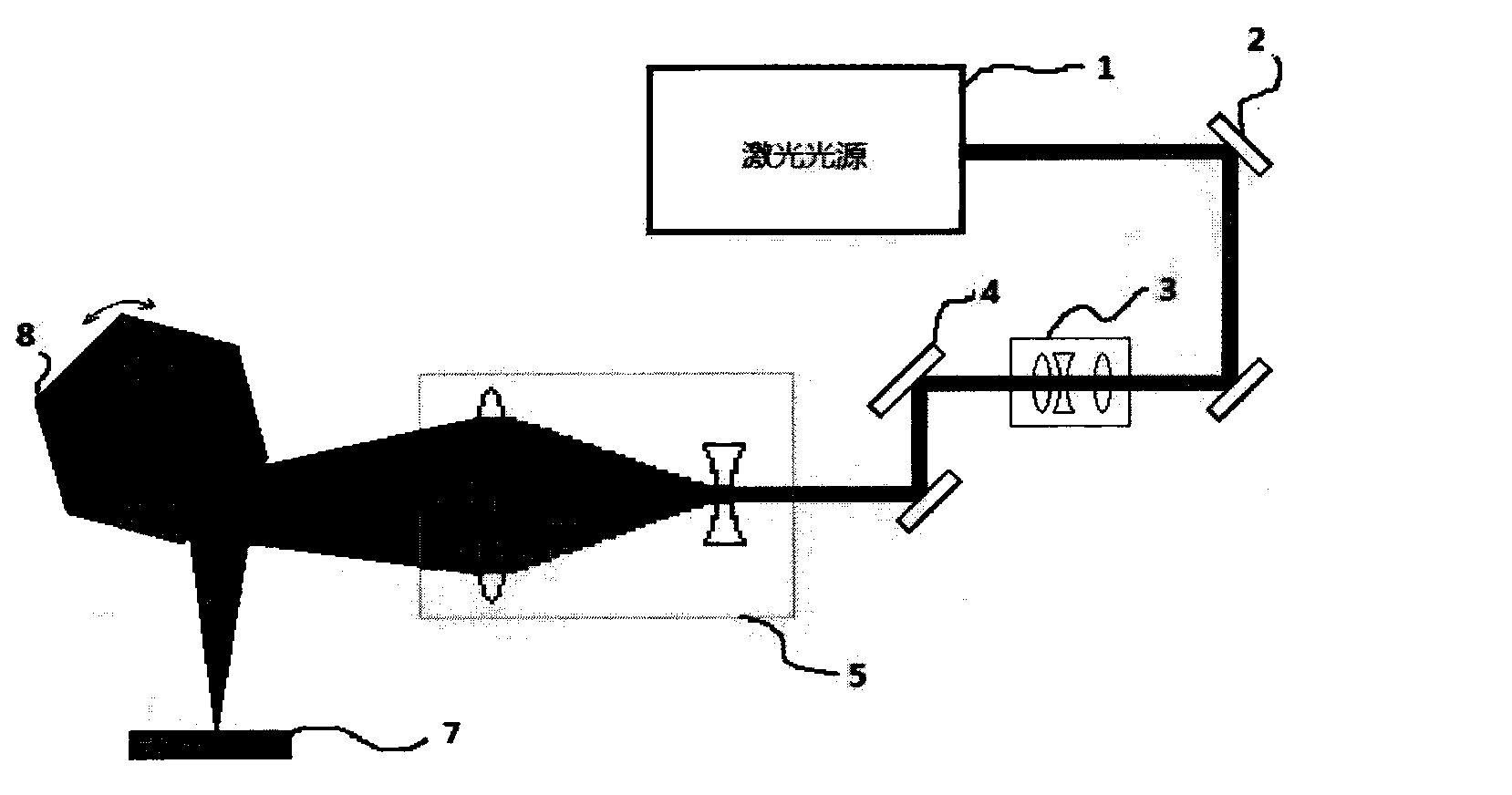

[0028] refer to figure 2, to fabricate a laser direct writing device that includes real-time shaping of liquid crystal light valves. The laser light source 1 selected by this device is a pulse laser produced by Beijing Guoke Century Laser Technology Co., Ltd., with a pulse width of 20 ns and a pulse repetition frequency of 1 kHz. The output formed by the laser light source 1 is deflected by the mirror group 2. The mirror group 2 includes two mirrors, which deflect the laser light emitted by the laser light source 1 to the required position and angle, and pass the pre-shaping from the center. Lens group 3. The front shaping lens group 3 includes 2 pieces of convex lens and 1 piece of concave lens, and its shaping diaphragm. The laser light emitted by the laser light source 1 is shaped to 20mm×15mm, and the aberration is eliminated. The laser beam emitted from the front shaping lens group 3 is irradiated on the liquid crystal light valve 4 . The liquid crystal light valve 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com