Wiredrawing method and wiredrawing device for outer diameter fluctuation optical fiber perform

An optical fiber preform and wire drawing technology, which is applied in the field of optical fiber processing and manufacturing, can solve problems such as uncontrollable outer diameter of bare optical fiber, damage to products and processing equipment, affecting optical fiber performance and strength, etc., so as to save consumption, optical fiber production capacity and processing Improve efficiency and ensure stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

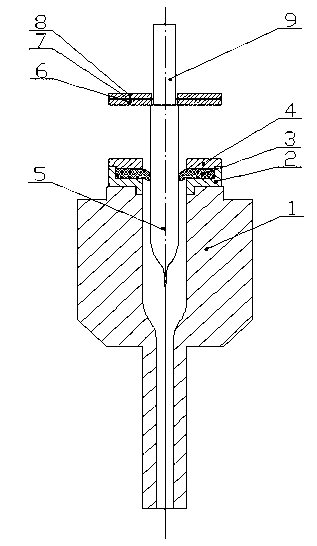

[0033] The wire drawing device used is such as figure 1 As shown, the drawing furnace body 1 is included. The drawing furnace body is provided with heating chambers penetrating up and down. The upper end of the heating chamber is provided with an inert gas blowing channel, and the upper end of the drawing furnace heating chamber is provided with a radial seal adjustable device. The said radial seal adjustable device includes a quartz glass base 2 installed on the furnace mouth at the upper end of the heating chamber, an annular groove is arranged on the upper end of the base, and a quartz wool sealing gasket 3 is arranged in the annular groove. It is composed of quartz wool strips, which are densely filled in the annular groove of the base, and a quartz glass gland 4 is arranged on the upper end of the base. The inner end surface of the quartz glass gland is provided with a boss and an annular groove for configuration.

[0034] The processing objects of this embodiment are listed...

Embodiment 2

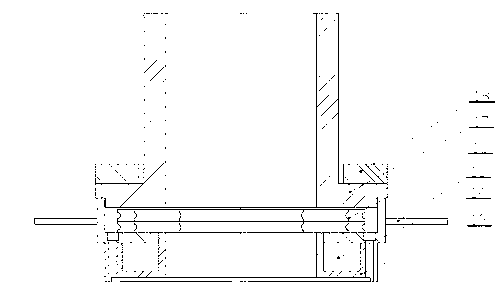

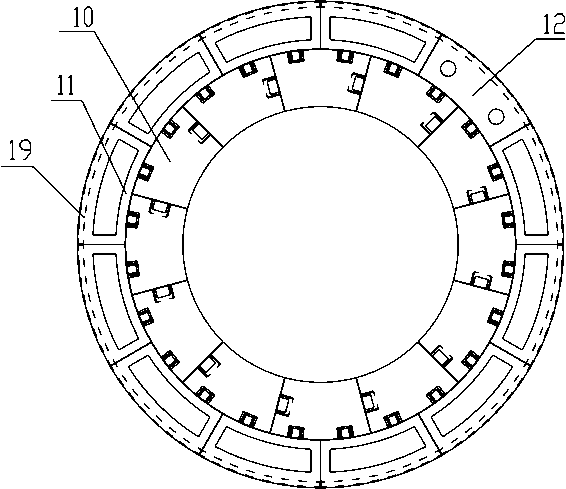

[0039] The wire drawing device used is such as Figure 2-4 As shown, the drawing furnace body 1 is included. The drawing furnace body is provided with heating chambers penetrating up and down. The upper end of the heating chamber is provided with an inert gas blowing channel, and the upper end of the drawing furnace heating chamber is provided with a radial seal adjustable device. The radial seal adjustable device includes a metal base 13, a boron nitride telescopic closed ring 16 and a quartz glass sleeve 17. The metal base is fixed to the furnace mouth at the upper end of the heating chamber, the lower end of the metal base is provided with an annular cooling water tank 14, and the upper end of the base An annular cavity is provided, a boron nitride telescopic closed ring is arranged in the annular cavity, and a quartz glass sleeve is arranged on the upper end of the annular cavity, thereby forming an annular cavity with an inner opening. The annular cavity and the protective g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com