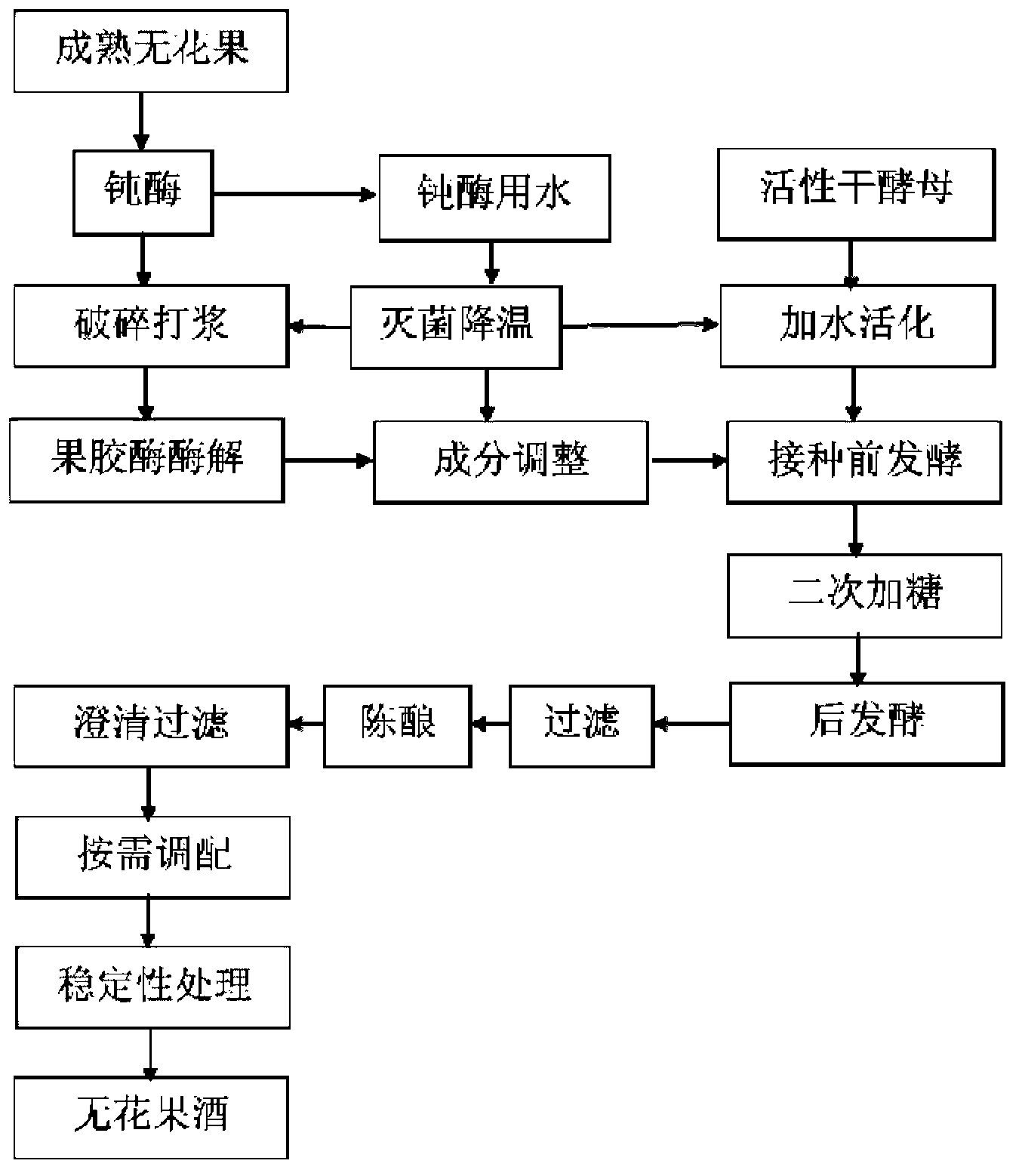

Production process of fig wine

A production process, fig technology, applied in the field of fig wine production process, can solve the problems of high content of methanol and fusel oil, achieve the effect of saving water resources and improving the accumulation of bad metabolites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

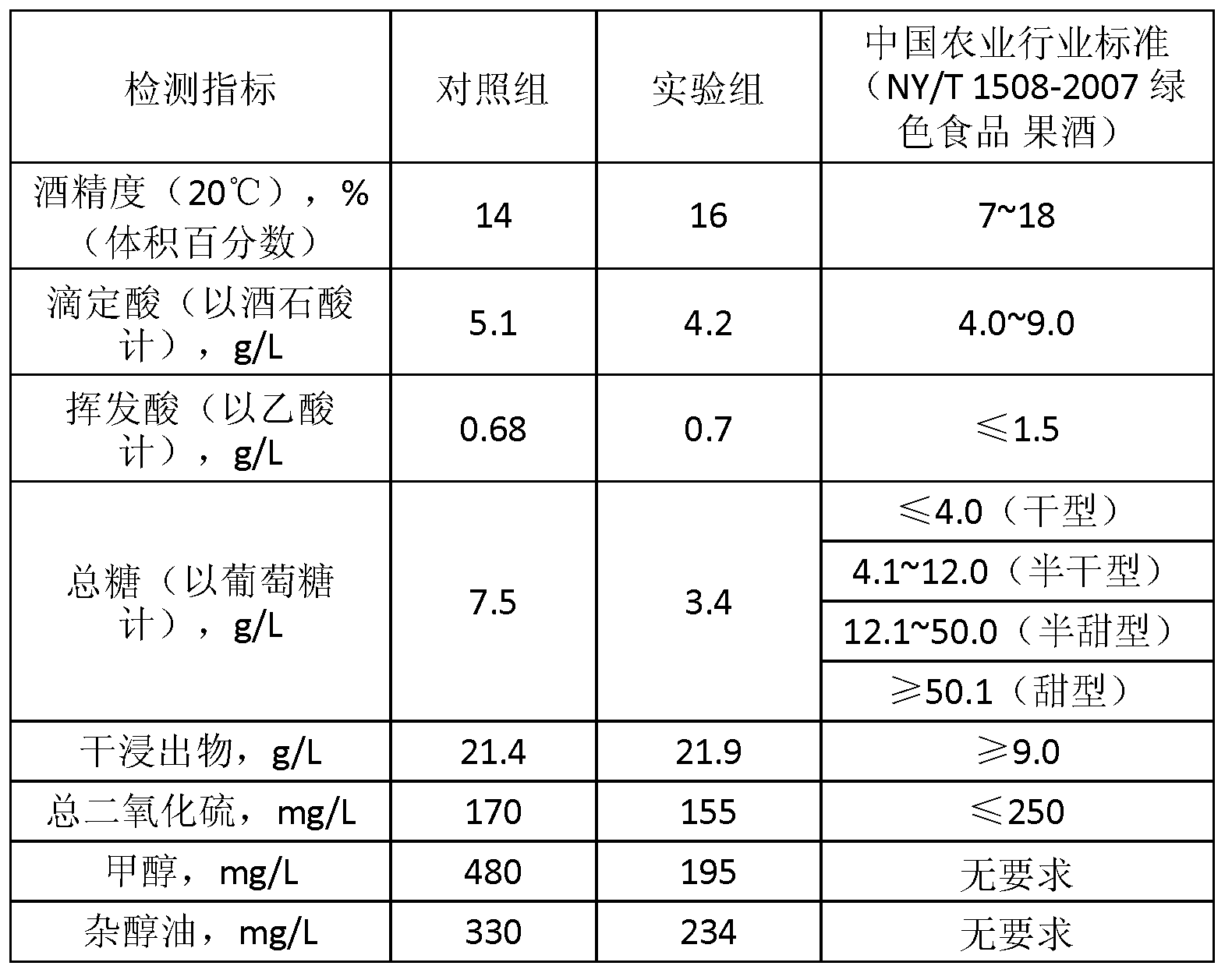

Embodiment 1

[0038] test group:

[0039] (1) Raw material screening: take green figs as raw material, get 2kg ripe figs, require fruit sugar content higher than 15%, and no disease, no rot, remove the stems and clean.

[0040] (2) Deactivated enzyme: The temperature of the water used for the deactivated enzyme can be controlled at 80°C and kept warm for 5 minutes. Try to completely immerse the figs in the water. Collect the blunt enzyme with water, sterilize it, and cool it down for later use.

[0041] (3) Crushing and beating: take the sterilized and cooled blunt enzyme water to 20% of the weight of figs, crush and beat them together with the fig raw materials, and add 80 ppm equivalent sulfur dioxide simultaneously.

[0042] (4) Pectinase enzymatic hydrolysis: The amount of pectinase added is 0.5g / L, the temperature is controlled at 45°C, and pectinase enzymatically hydrolyzed for about 2 hours.

[0043] (5) Component adjustment: add white sugar to the fig pulp after pectinase enzymoly...

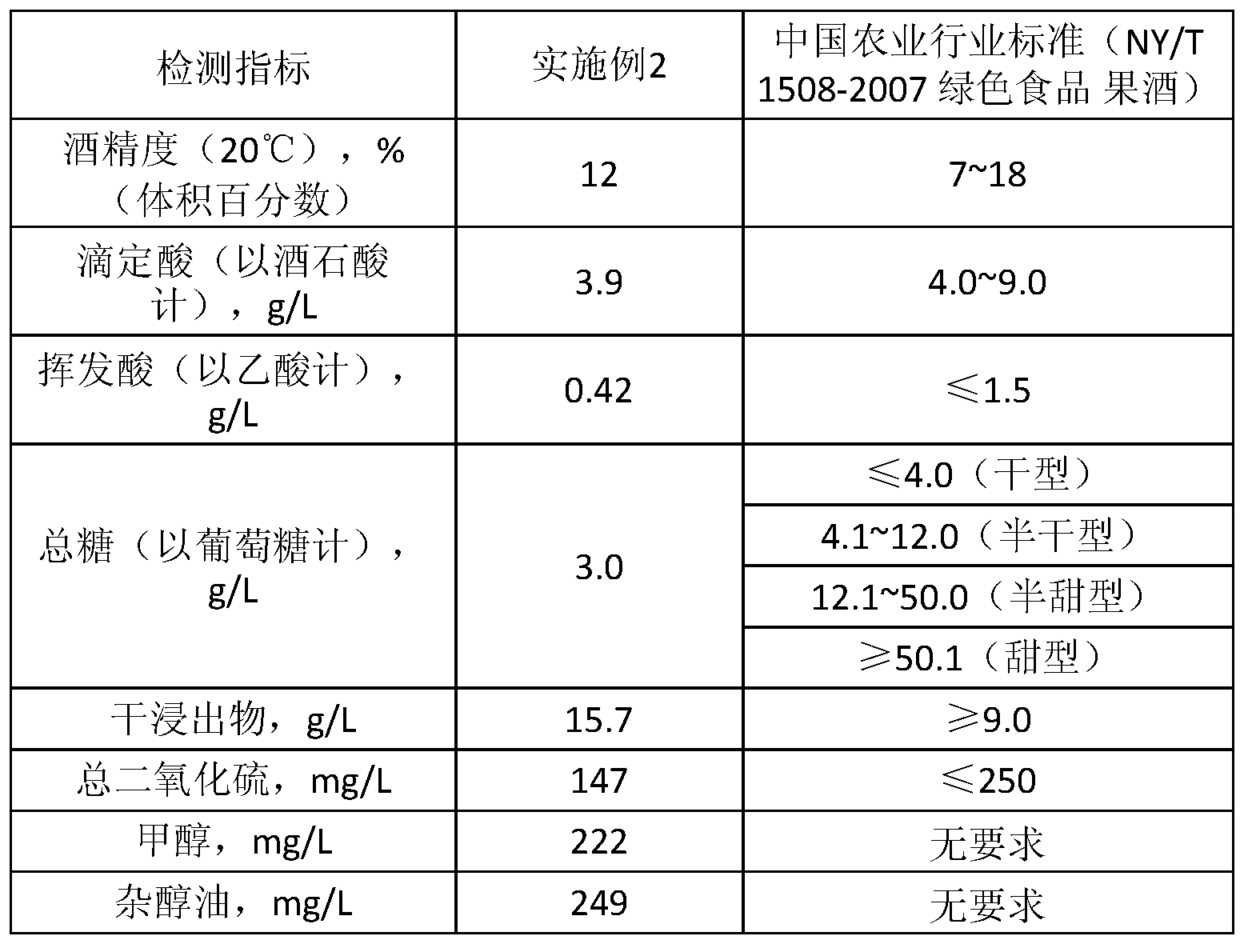

Embodiment 2

[0055] (1) Raw material screening: take Branschweig fig as raw material, take 3 kg of ripe fig, require the fruit sugar content to be higher than 15%, and have no disease or rot, remove the stems and clean.

[0056] (2) Deactivated enzyme: The temperature of the water used for the deactivated enzyme can be controlled at 80°C for 10 minutes, and the figs should be fully immersed in the water as much as possible. Collect the blunt enzyme with water, sterilize it, and cool it down for later use.

[0057] (3) Crushing and beating: take the sterilized and cooled blunt enzyme water to 20% of the weight of figs, crush and beat them together with the fig raw materials, and add 75ppm equivalent sulfur dioxide simultaneously.

[0058] (4) Pectinase enzymatic hydrolysis: The amount of pectinase added is 0.5g / L, the temperature is controlled at 45°C, and pectinase enzymatically hydrolyzed for about 2 hours.

[0059] (5) Component adjustment: add white sugar to the fig pulp after pectinas...

Embodiment 3

[0069] (1) Raw material screening: take Branschweig fig as raw material, take 5.1 kg of ripe fig, require the fruit sugar content to be higher than 15%, and have no disease or rot, remove the stems and clean.

[0070] (2) Deactivated enzyme: The temperature of the water used for the deactivated enzyme can be controlled at 80°C for 5 minutes, and the figs should be fully immersed in the water as much as possible. Collect the blunt enzyme with water, sterilize it, and cool it down for later use.

[0071] (3) Crushing and beating: take the sterilized and cooled blunt enzyme water to 20% of the weight of figs, crush and beat them together with the fig raw materials, and add 100 ppm equivalent sulfur dioxide simultaneously.

[0072] (4) Enzymatic hydrolysis of pectin: The amount of pectinase added is 0.3g / L, the temperature is controlled at 45°C, and pectinase is hydrolyzed for about 2 hours.

[0073] (5) Component adjustment: add white sugar to the fig pulp after pectinase enzymo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com