Method for determining valence state of transition metal in slag by using high-temperature mass spectrum method

A transition metal, high-temperature technology, applied in the field of analysis of the valence state of melt ions, can solve the problems of acid oxidation, hidden dangers, and inability to be widely used, which are difficult to eliminate oxidation, and achieve good application prospects, easy to implement, and reliable Transplantation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

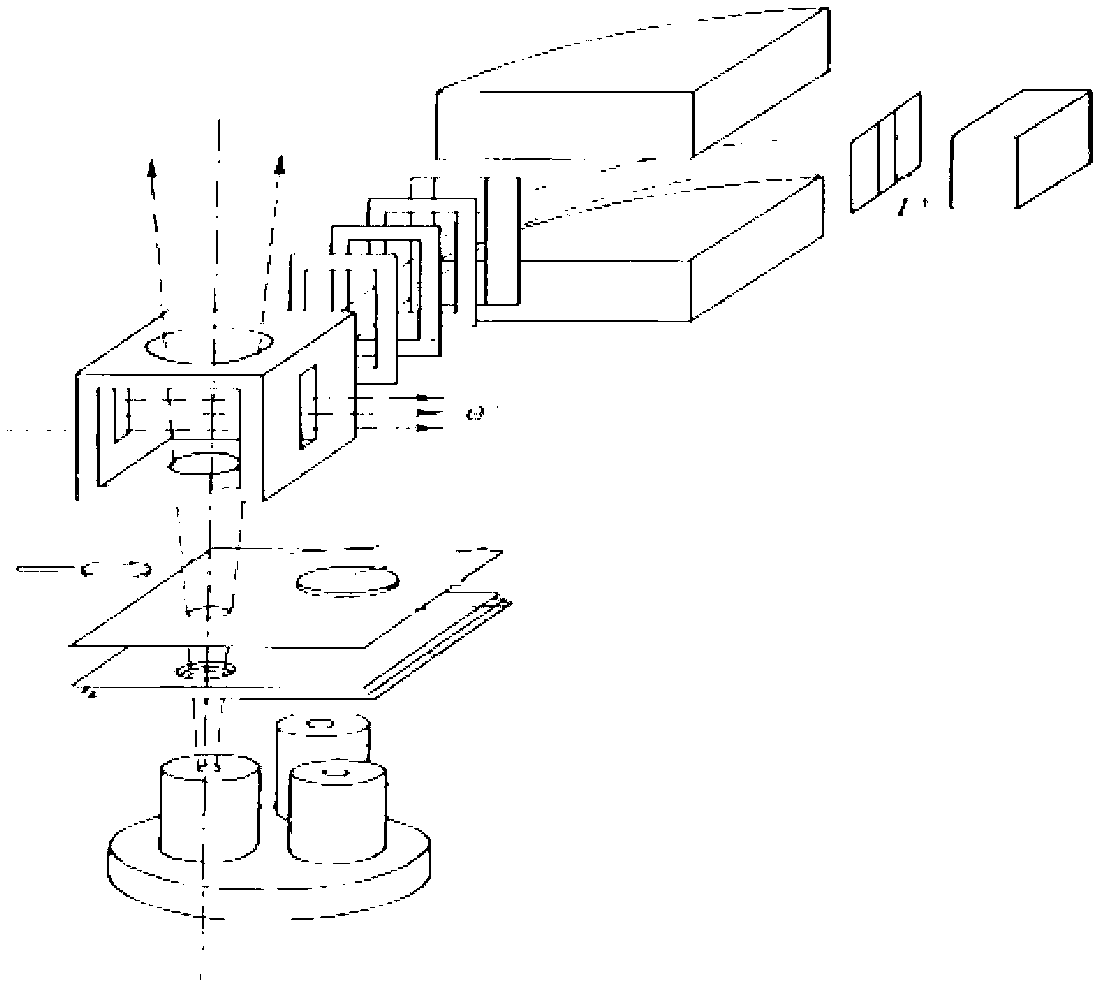

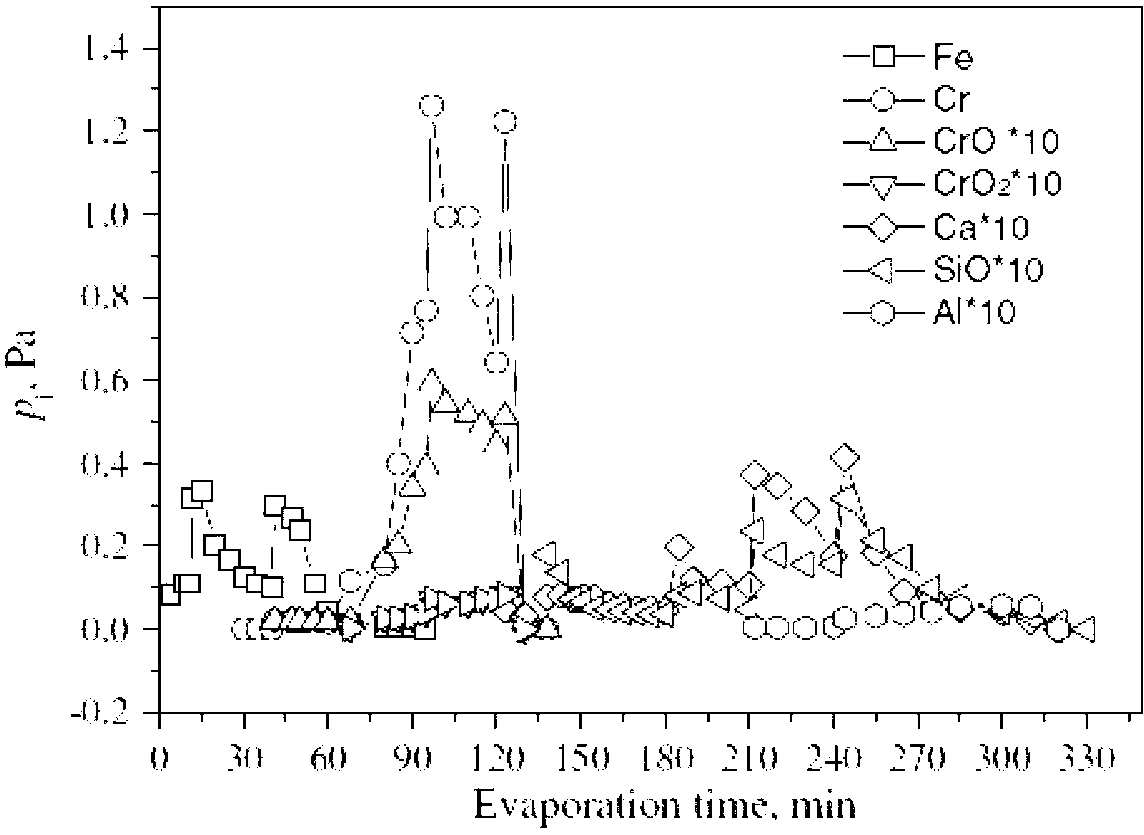

[0032] Experiments were carried out using double tungsten Knudsen cells, one of which was filled with pure Cr 2 o 3 The sample serves as a standard, and a slag sample is placed in another cell. The system is calibrated with liquid gold. In CaO-MgO-Al 2 o 3 -Cr 2 o 3 -FeO-SiO 2 During the volatilization process, CrO in the gas phase + and CrO 2 + The ionic current intensity was recorded by the mass spectrometer and compared with the reference sample Cr 2 o 3 The volatilization process was compared.

[0033] 2: Analysis method

[0034] In the temperature range of 1850-2000K, there are three kinds of Cr-containing gas phase substances, namely Cr, CrO and CrO 2 . From the standard sample Cr 2 o 3 It can be seen that the possible reactions between the three substances are as follows:

[0035] Cr 2 o 3 (solid)=2Cr(gas)+3O(gas) (1)

[0036] Cr 2 o 3 (solid)=2CrO(gas)+O(gas) (2)

[0037] Cr 2 o 3 (solid)=CrO 2 (gas)+CrO(gas) (3)

[0038] And according to li...

Embodiment 2

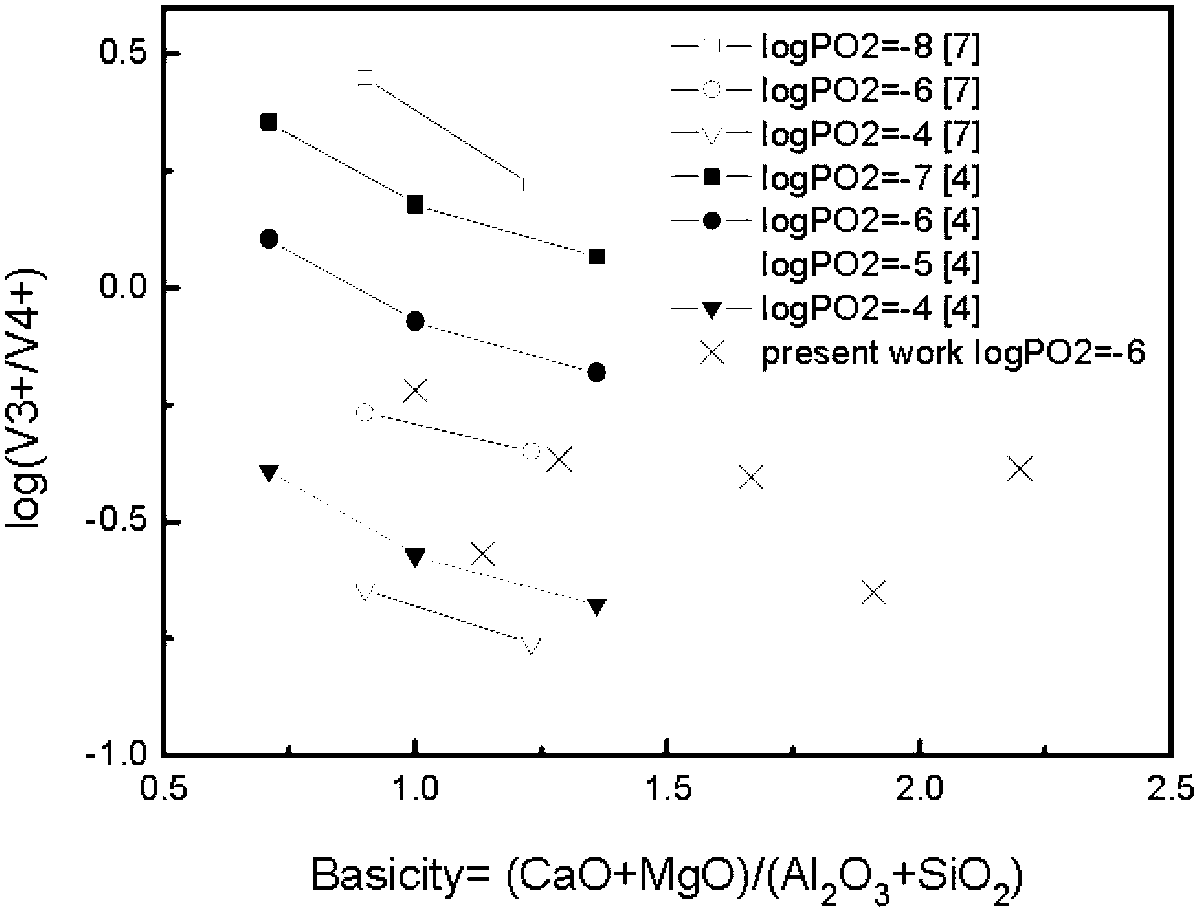

[0042] Taking the analysis of the valence state of V in slag as an example, starting from the literature, we can make a judgment that there may be a valence state, and then study the 3+ / V 4+ price ratio.

[0043] 1. At alkalinity (CaO / SiO 2 ) is less than 1 and the partial pressure of oxygen is less than 10 -1 Pa, only V 3+ and V 4+ coexist. Considering the reality of low oxygen partial pressure in the steelmaking process and the low oxygen partial pressure conditions in the process of high-temperature mass spectrometry, the influence of alkalinity is ignored here, and it is considered that V 3+ and V 4+ is the main valence state present in the studied slag samples. This assumption is consistent with V 5+ The fact that it cannot exist under conditions of low oxygen partial pressure.

[0044] 2. The slag sample chamber is volatilized from two parallel Knudsen pools, and the ratio of the volatilization gap to the volatilization area of the Knudsen pool is 1:100. Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com