Machine for welding border angle steel and connection sleeve of standard section of tower crane

A tower crane, connecting sleeve technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of unstable surface quality of angle steel and sleeve welding, high labor intensity, and high robot price. The welding quality is stable and reliable, the processing quality is improved, and the effect of avoiding uneven feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

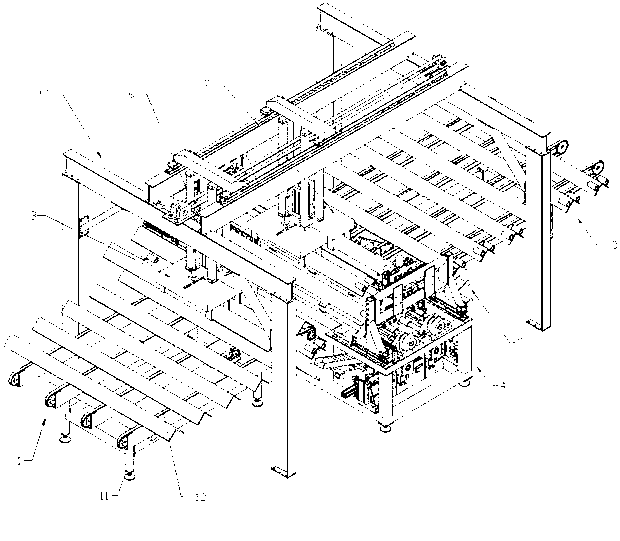

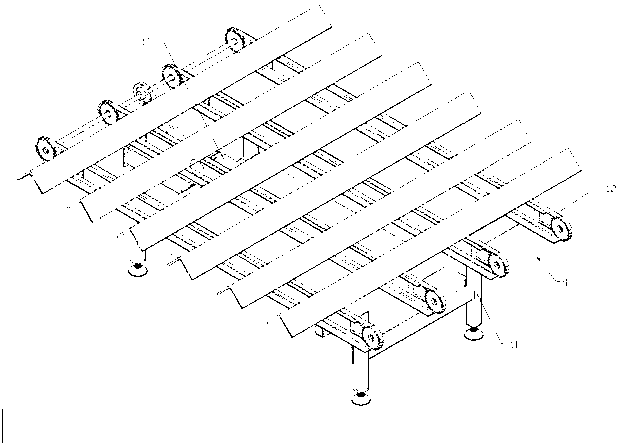

[0048] Refer to attached figure 1 to attach Image 6 , as shown in the accompanying drawings, the present invention provides a welding machine for angle steel and connecting sleeves for the frame of a standard section of a tower crane, including:

[0049] Conveying mechanism 1, conveying the angle steel placed on it to the handling position;

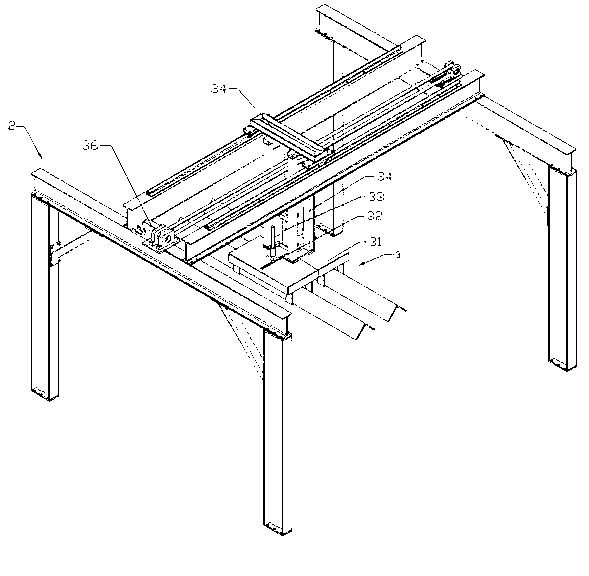

[0050] The transport frame 2 spans the entire automatic line;

[0051] The transport mechanism 3 clamps the angle steel at the transport position, and is driven by the transport drive device 36 to move on the transport frame 2 and transport the angle steel to the clamping position;

[0052] Welding mechanism, the welding mechanism includes a rotary positioning device 4, a sleeve feeding mechanism 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com