Intelligent drilling control system and method for petroleum drilling machine

A control system and intelligent technology, applied in the automatic control system of drilling, drilling equipment, earthwork drilling, etc., can solve problems such as difficulty in establishing mathematical models, and achieve the effects of reducing drill bit wear, reducing labor intensity, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

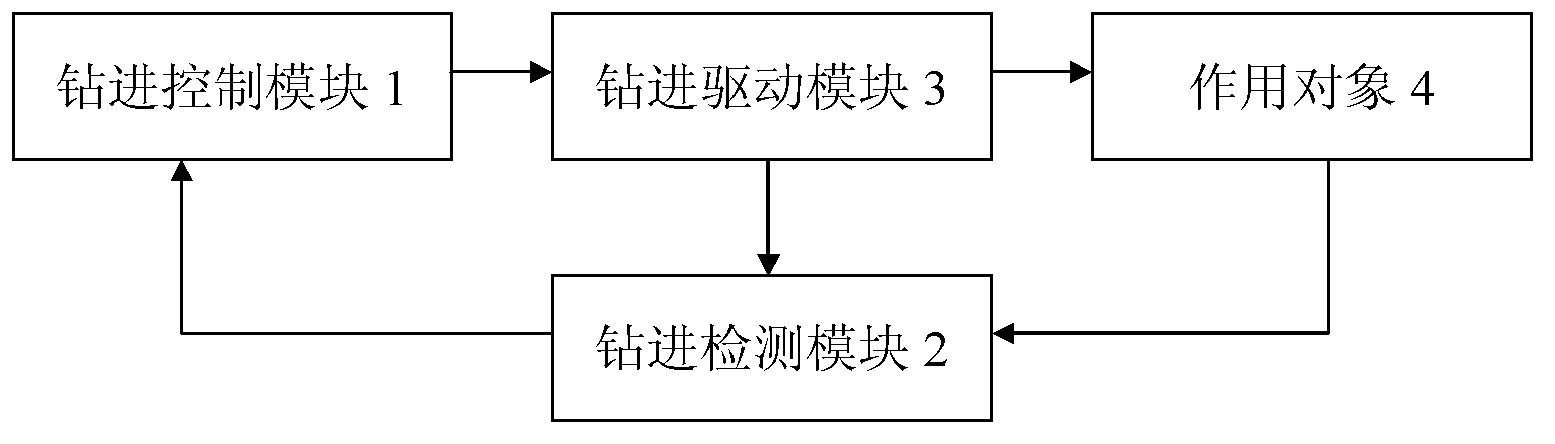

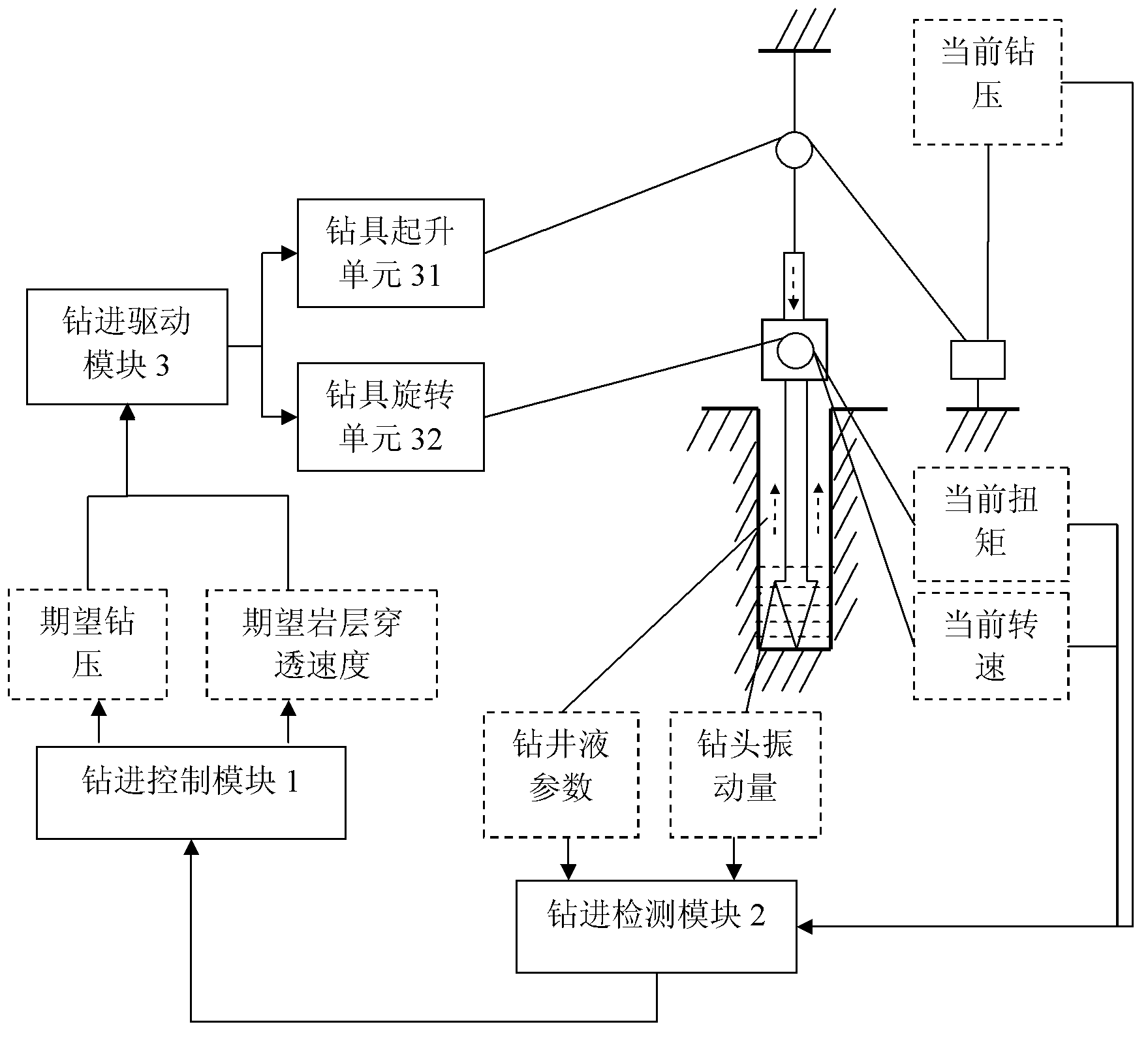

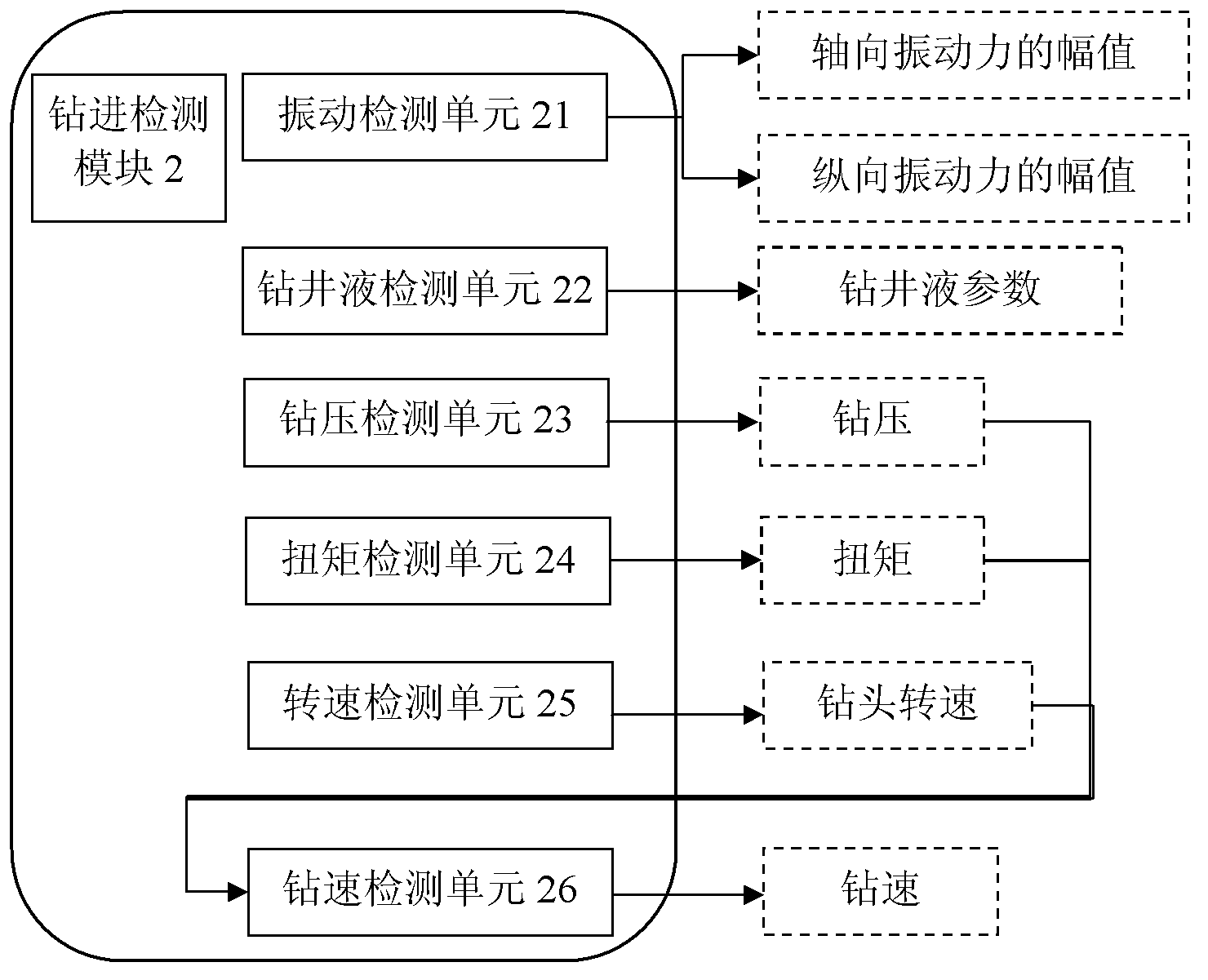

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0025] During the drilling process of oil drilling rigs, due to the diversity of rock mass structures downhole, when the front end of the drill bit touches rocks of different properties, excessive drilling pressure and drilling speed may cause accidents, such as broken drill pipes, drill bits, and drill bits. Damage, etc.; too low drilling pressure, drilling speed and torque make drilling efficiency very low. Therefore, in a certain formation and a certain depth, proper drilling pressure, drilling speed and torque are very beneficial to drilling, which can not only improve drilling efficiency, but also help reduce drill bit wear.

[0026] When the oil drilling rig comes into contact with rocks of different properties, if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com