Gear box shifting fork

A gearbox and fork support technology, which is applied in the field of mechanical transmission, can solve the problems of increasing the manufacturing cost of the shift fork block 3, affecting work efficiency, frequent operation of the shift fork, etc., and achieves the advantages of convenient purchase and replacement, convenient processing and assembly, and flexible rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

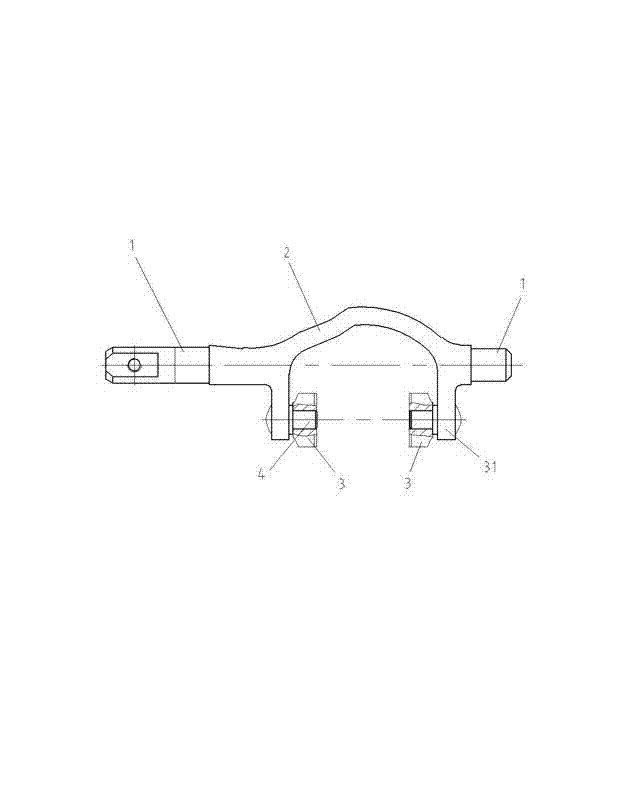

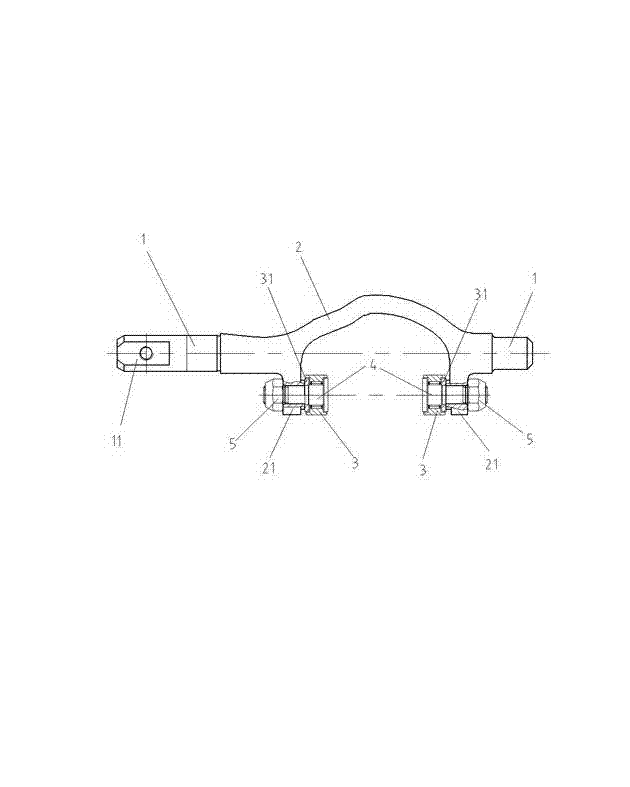

[0013] Such as figure 2 As shown, the present invention includes shift fork support shafts 1 at both ends, and a bow-shaped shift fork body 2 connecting the shift fork support shafts 1 at both ends. One of the shift fork support shafts 1 extends out of the end 11 connected to the operating handle, and the bow-shaped shift fork The two ends of the main body 2 respectively extend downwards the lower head 21 which is perpendicular to the support shaft 1 of the shift fork. On the lower head 21. The shift fork block is a needle roller bearing 3 without an inner ring, and its radial dimension is small, which meets the requirement of matching with the annular groove of the duplex gear. The support shaft 4 is a matching piece of the needle roller bearing 3 without an inner ring roller, and has a stepped shaft structure. The needle roller bearing 3 without an inner ring roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com