Method for assessing settleability and uniformity of lithium ion battery cathode slurry

A lithium-ion battery and negative electrode material technology, applied in the direction of weighing by removing certain components, can solve problems such as unevenness, poor consistency of coated pole pieces, and sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

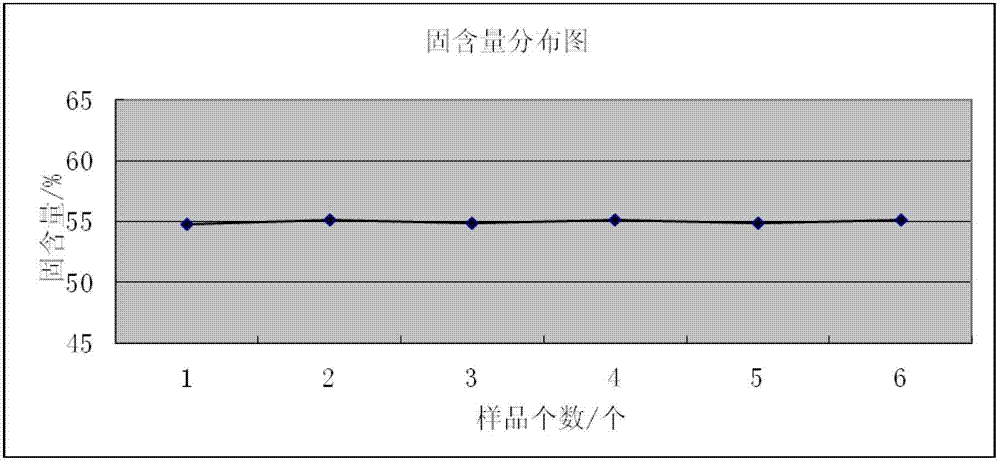

Embodiment 1

[0034] The components of a lithium titanate slurry, a negative electrode material for lithium ion batteries, are shown in Table 1, and its theoretical solid content is 42.00%.

[0035] Table 1 Lithium titanate slurry composition list of lithium ion battery anode material

[0036] Element

conductive agent

binder

Proportion (%)

49.00

2.00

4.00

45.00

[0037]A method for evaluating the settling and uniformity of lithium-ion battery negative electrode material lithium titanate slurry, comprising the following steps:

[0038] (1) Take lithium titanate slurry, the negative electrode material of lithium ion battery, and stir it evenly. Take 3 samples randomly from different positions in the slurry tank, namely A, B, and C. Mark the samples and perform centrifugation at a speed of 500rmp , the centrifugation time is 8min;

[0039] (2) Divide the three centrifuged samples into upper and lower sam...

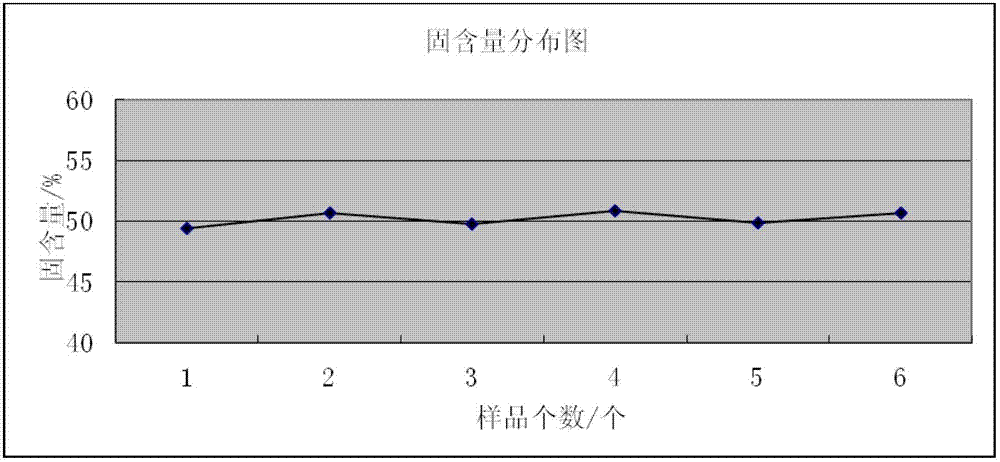

Embodiment 2

[0051] A lithium ion battery negative electrode material graphite slurry components are shown in Table 3, and its theoretical solid content is 45.00%.

[0052] Table 3 Components of graphite slurry for lithium-ion battery anode materials

[0053] Element

graphite

conductive agent

binder

Proportion (%)

44.00

2.00

4.00

50.00

[0054] A method for evaluating the settling and uniformity of lithium-ion battery negative electrode material graphite slurry, comprising the following steps:

[0055] (1) Take the graphite slurry of lithium-ion battery negative electrode material, stir it evenly, randomly take 3 samples from different positions of the slurry barrel, namely A, B, and C, mark the samples and perform centrifugation at a centrifugal speed of 1000rmp. The time is 10 minutes;

[0056] (2) Divide the three centrifuged samples into upper and lower samples according to the volume, which are A 1 、A 2 , B 1...

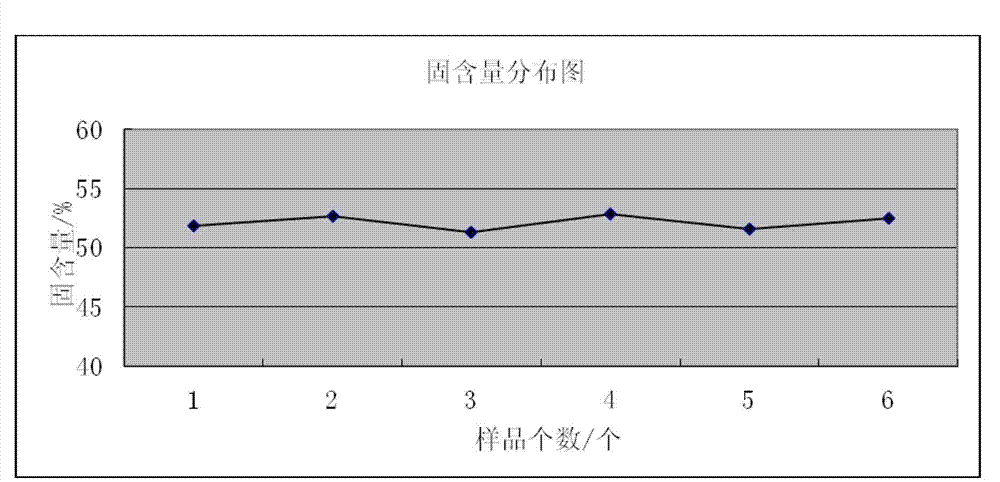

Embodiment 3

[0069] A lithium ion battery negative electrode material graphite slurry components are shown in Table 5, and its theoretical solid content is 40.00%.

[0070] Table 5 Components of graphite slurry for lithium-ion battery anode materials

[0071] Element

graphite

conductive agent

binder

Proportion (%)

46.00

2.00

4.00

48.00

[0072] A method for evaluating the settling and uniformity of lithium-ion battery negative electrode material graphite slurry, comprising the following steps:

[0073] (1) Take the graphite slurry of lithium-ion battery negative electrode material, stir it evenly, randomly take 3 samples from different positions of the slurry barrel, namely A, B, and C, mark the samples and perform centrifugation at a centrifugal speed of 2000rmp. The time is 5 minutes;

[0074] (2) Divide the three centrifuged samples into upper and lower samples according to the volume, which are A 1 、A 2 , B 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com