Functional block with FF (foundation fieldbus) interface

A technology of interface function and function block, applied in the field of industrial automation control and field bus, can solve the problem of high network load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

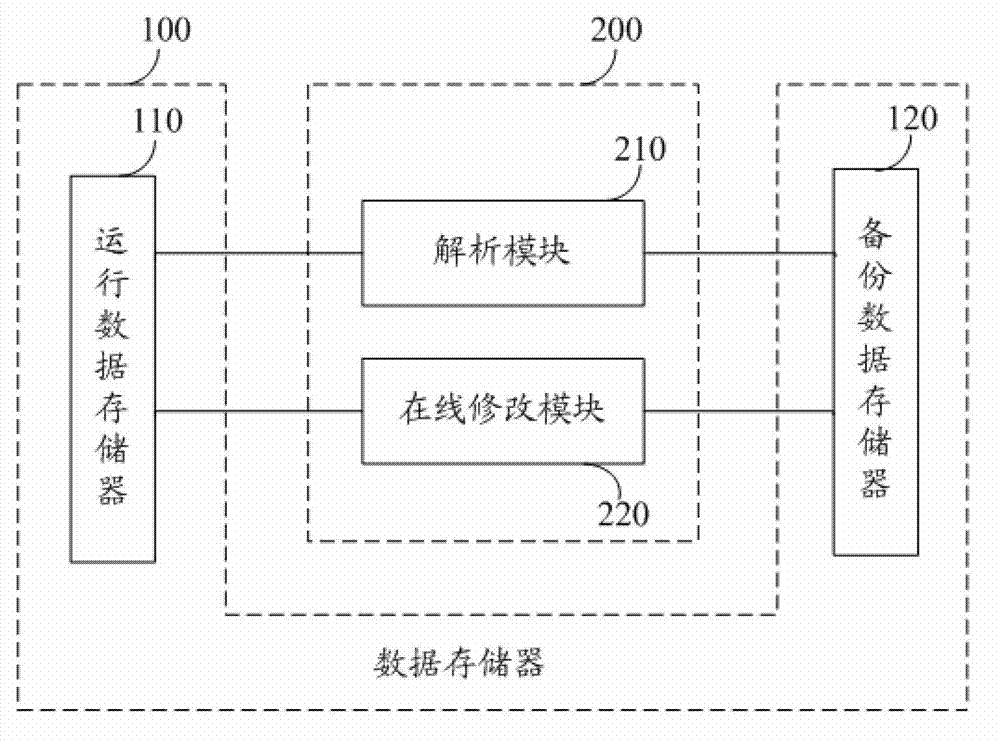

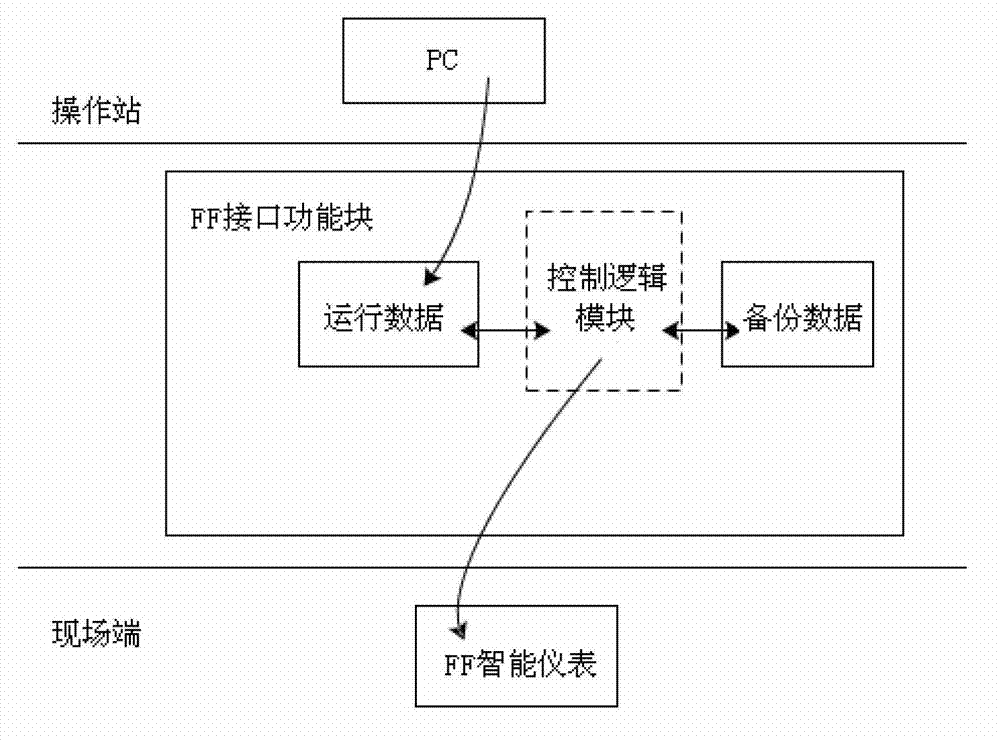

[0057] See figure 2 , figure 2 A structure of the above-mentioned FF interface function block is shown, which includes a data storage 100 and a control logic module 200, wherein the data storage 100 includes a running data storage 110 and a backup data storage 120, and the control logic module 200 includes an analysis Module 210 and Online Modification Module 220.

[0058] The analysis module 210 is configured to analyze the instrument real-time data of the instrument function block, and update the analyzed data to the operation data storage 110 and the backup data storage 120 .

[0059] The running data memory 110 is used for displaying and modifying the data of the external upper module of the DCS.

[0060] Specifically, the operating data memory 110 is used as a data buffer area open to the external upper layer modules of the DCS, and the external upper layer modules of the DCS such as the operating station or the engineer station can be used as a host computer to read ...

Embodiment 2

[0071] On the basis of the first embodiment above, please refer to Figure 4 , in Embodiment 2 of the present invention, the data storage 100 may further include a raw data storage 130, which is used to receive and buffer real-time data of the instrument sent by the functional block of the instrument.

[0072] Specifically, the original data storage 130 is the receiving buffer for the data sent by the instrument function block, which defines the data structure according to the FF standard protocol. The original data storage 130 includes three independent units: the second view data storage, the third view data storage and the fourth view data memory, respectively used to store the view in the instrument function block figure 2 ,See image 3 And as Figure 4 data.

[0073] In the second embodiment, the parsing module is specifically configured to parse the data in the original data storage, and update the parsed data to the running data storage and the backup data storage. ...

Embodiment 3

[0076] On the basis of the first and second embodiments above, in the third embodiment of the present invention, the control logic module may further include a data update module, a pin state processing module and a process alarm processing module, wherein:

[0077] Data update module, used for view channel data update and fast channel data update;

[0078] The pin state processing module is used for adaptive processing of the pin state of the pins in the DCS and the pins in the instrument function block;

[0079] The process alarm processing module is used to enable and indicate the process alarm of the instrument function block.

[0080] The structures and functions of other modules are the same as those in Embodiment 1 or Embodiment 2. Please refer to the relevant content in Embodiment 1 or 2 for details, and will not be described in detail here.

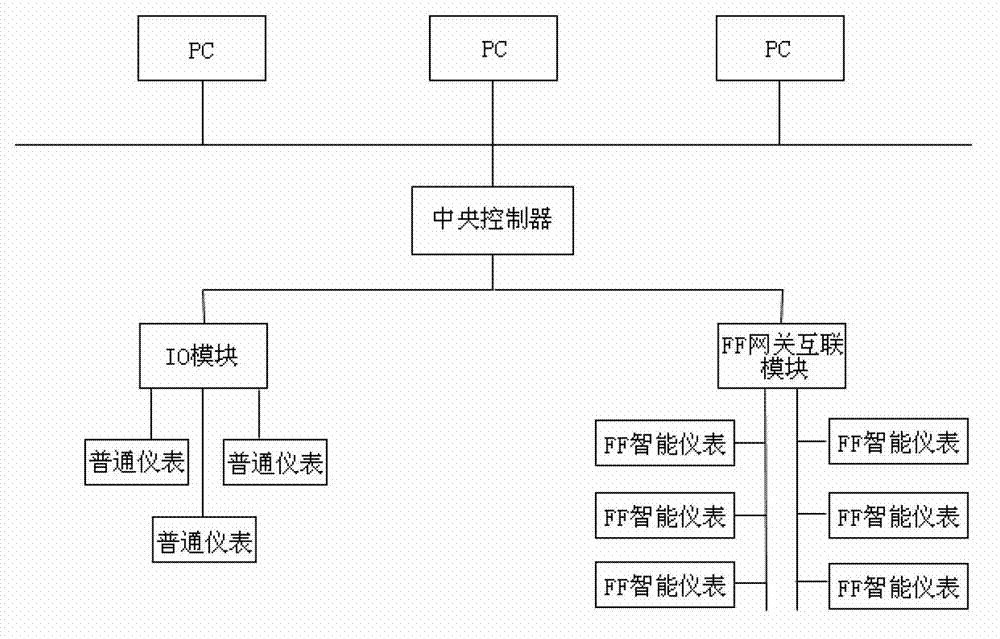

[0081]In the present invention, the FF interface function block is built in the central controller of the DCS, and is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com