Electric heating pipe manufacturing method

A technology of electric heating tube and manufacturing method, which is applied in the direction of heating element shape, etc., which can solve the problems of high resistance wire strength, high resistance wire bending strength, and the inability of wire winding machine to wind wire, so as to increase service life and increase creepage distance , Guarantee the effect of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

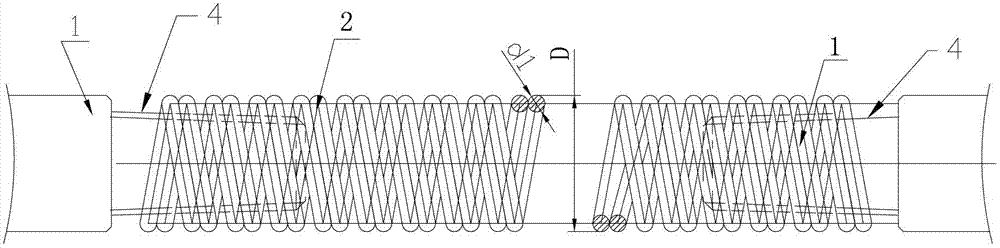

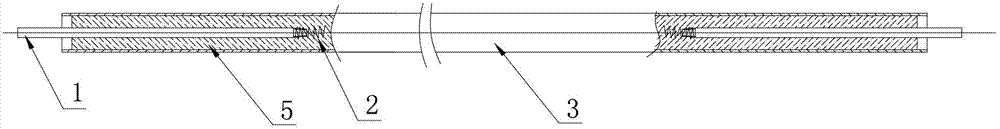

[0018] Due to the limitations of the pipe materials selected for household electric heating pipes (Φ6.2mm, 6.5mm, 8.0mm, 8.5mm), if the resistance wire of the electric heating pipe adopts the structure of a parallel double resistance wire circuit, the rated voltage is small and the rated power is large. The electric heating tube can be processed with the smaller diameter of the resistance wire. The diameter of the electric heating tube is Φ6.2mm, the wall thickness is 0.5mm, and the outer diameter D of the resistance wire coil is controlled at Φ1.8~2.6mm; 5mm, the wall thickness is 0.5mm, the outer diameter D of the resistance coil is controlled at Φ1.8~2.8mm; the pipe diameter is Φ8.0mm, the wall thickness is 0.5mm, the outer diameter D of the resistance coil is controlled at Φ1.8~4.3mm ;The pipe diameter is Φ8.5mm, the wall thickness is 0.5mm, and the outer di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com