Seal tape, light modulating element, light modulating structure and method for producing light modulating structure

A technology of dimming components and sealing tapes, applied in optics, shading screens, nonlinear optics, etc., can solve problems such as liquid crystal layer degradation and liquid crystal layer infringement, and achieve the effects of improving workability, preventing damage, and preventing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

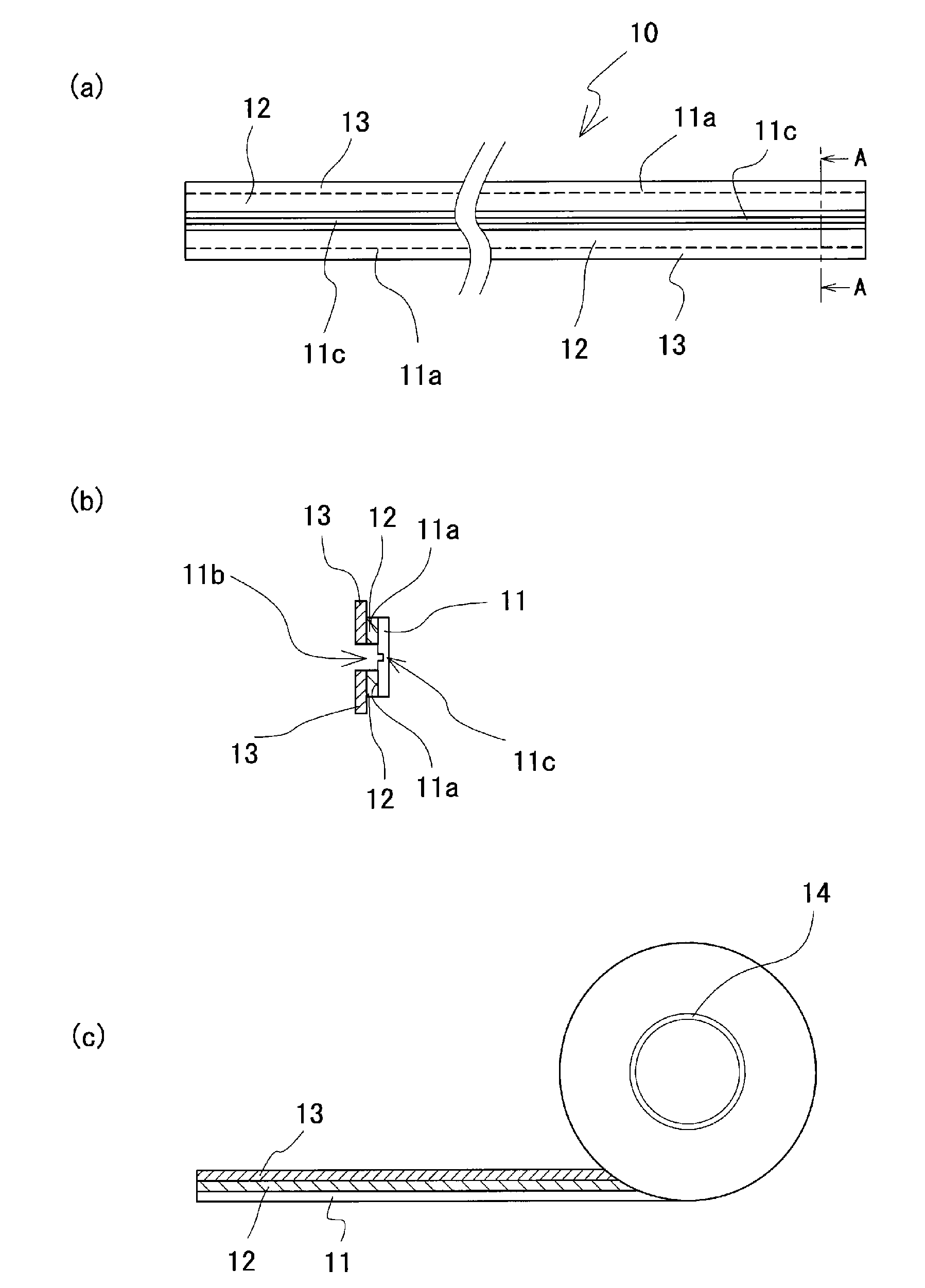

[0046] Such as figure 1 As shown, the sealing tape 10 includes: a strip-shaped base material 11; an adhesive portion 12 formed by disposing an adhesive on both edge portions 11a in the longitudinal direction of the base material 11; The area between the two edge portions 11a of the base material 11 is exposed along the length direction of the base material 11;

[0047] The base material 11 is a film with transparency, insulation, flexibility, toughness, heat resistance, cold resistance or chemical corrosion resistance, such as a polyester film, especially polyethylene terephthalate : PET) film. In addition, the base material 11 which concerns on this embodiment uses "Lumira (registered trademark)" manufactured by Toray Co., Ltd. with a width of 6 mm.

[0048] Adhesive portion 12 may be formed by directly applying an adhesive to base material 11 and drying the applied adhesive, or may be formed by affixing one side of the base material 11 with a double-sided adhesive tape. I...

no. 2 approach )

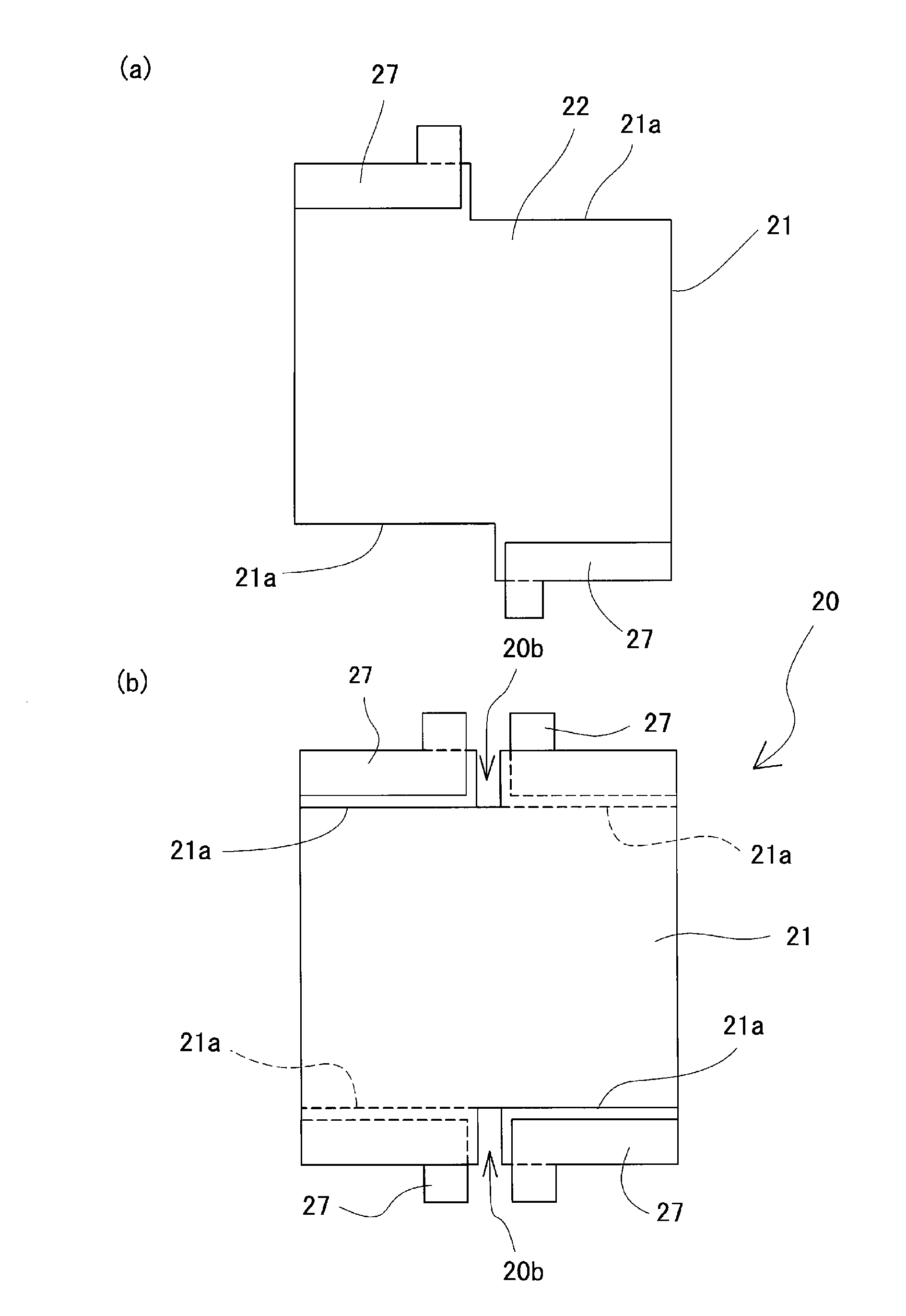

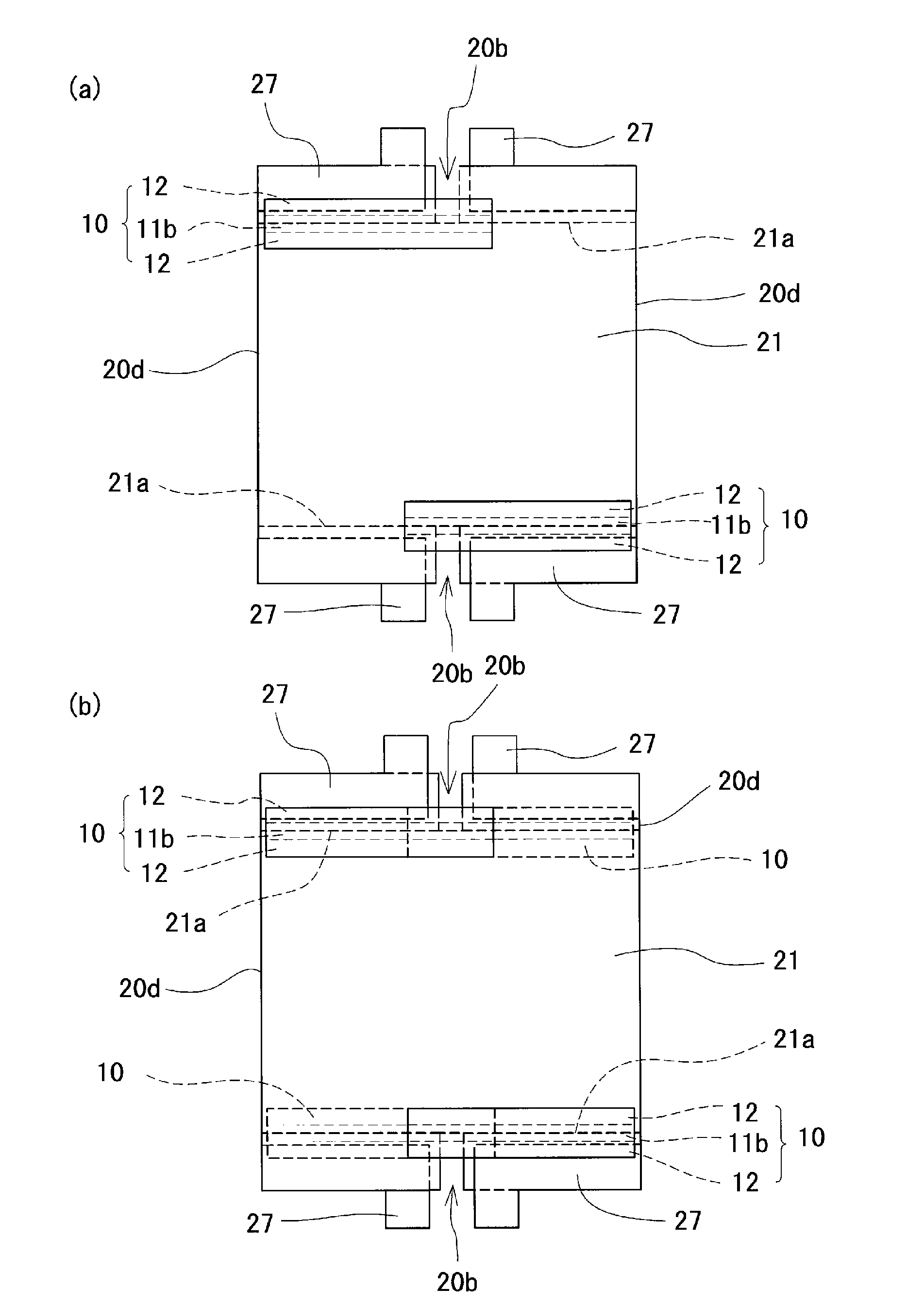

[0099] Figure 7 (a) is a plan view of an insulating substrate provided with a transparent electrode and an extraction electrode, Figure 7 (b) is used to illustrate Figure 7 (a) is a perspective view of opposing surfaces of two insulating substrates. Figure 8 (a) is a plan view showing a schematic configuration of the light control element according to the second embodiment, Figure 8 (b) is from Figure 8 (a) A side view of the four sides of the dimming element as viewed from the side where terminals protrude. Figure 9 (a) is at Figure 8 (a) The top view of the dimming element with the sealing tape attached to the half-cut line on the surface side of the dimming element, Figure 9 (b) is at Figure 9 (a) is a plan view of a light-adjusting element with a sealing tape attached to the half-cut line on the rear side of the light-adjusting element. Figure 10 (a) is at Figure 9 (b) A top view of the dimming element with the sealing tape 10 attached to the side where...

Embodiment 2

[0140] The dimming element 20 involved in Embodiment 2 is in Figure 13 In the plan view shown in (a), one side of the substantially rectangular insulating substrate 21 is cut so that the completely broken region 20 b is located in the substantially center of one of the four sides of the light-adjusting structure 100 , and the two cut insulating substrates are overlapped. The permanent substrate 21 is used to form a fully disconnected region 20b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com