Analyzing and monitoring method for circulating mother liquor during production of 1,2-dichloroethane

A technology of circulating mother liquid and dichloroethane, which is applied in the direction of analyzing materials, measuring devices, and material separation, can solve the problems of unsatisfied, unseen, and lack of standards and specific methods for analysis and monitoring, and achieve accurate analysis results and easy operation. Simple process and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

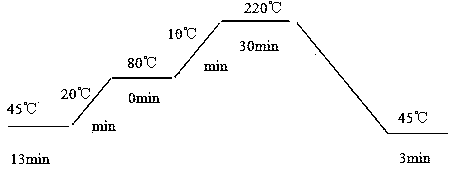

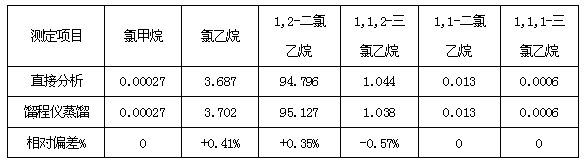

Embodiment 1

[0054] Embodiment 1: Get production mother liquor 80mL, weigh 108.216g, filter with weighed filter paper, after filtering, weigh the quality of filter paper and residue, obtain the quality of residue 2.651g; Mother liquor after filtration uses distillation range measurement For instrumental distillation, the condensation temperature of the distillation system is set to 0°C in advance, and the receiving bottle is installed so that the liquid outlet at the end of the condenser tube is at the bottom of the receiving bottle, and the bottle mouth is kept airtight. After reaching the set condensation temperature, take the filtered production mother liquor into the distillation flask, insert a thermometer, and adjust the position of the distillation flask to make it stand upright. Connect the branch pipe of the distillation flask to the condensation pipe tightly with a silicone rubber stopper, and the branch pipe goes deep into the condensation pipe 25 ~ 50mm, gradually increase the d...

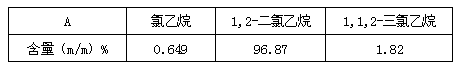

Embodiment 2

[0068] Example 2: Take 50 mL of the production mother liquor, weigh 67.521 g, filter with weighed filter paper, weigh the quality of the filter paper and the residue after filtration, and obtain the quality of the filter residue of 1.663 g. The filtered mother liquor is distilled using a distillation range tester. Set the condensation temperature of the distillation system to -10°C in advance, install the receiving bottle so that the liquid outlet at the end of the condenser tube is at the bottom of the receiving bottle, and keep the bottle mouth tightly closed. After reaching the set condensation temperature, take the filtered production mother liquor into the distillation flask, insert a thermometer, and adjust the position of the distillation flask to make it stand upright. Connect the branch pipe of the distillation flask to the condensation pipe tightly with a silicone rubber stopper, and the branch pipe goes deep into the condensation pipe 25 ~ 50mm, gradually increase t...

Embodiment 3

[0082] Example 3: Take 80mL of the production mother liquor, weigh 107.932g, filter with weighed filter paper, weigh the quality of the filter paper and the residue after filtration, and obtain the quality of the filter residue 2.638g. The filtered mother liquor is distilled using a distillation range tester. Set the condensation temperature to 8°C, install the receiving bottle so that the liquid outlet at the end of the condenser tube is at the bottom of the receiving bottle, and keep the bottle mouth tightly closed. After reaching the set condensation temperature, take the filtered production mother liquor into the distillation flask, insert a thermometer, and adjust the position of the distillation flask to make it stand upright. Connect the branch pipe of the distillation flask to the condensation pipe tightly with a silicone rubber stopper, and the branch pipe goes deep into the condensation pipe 25-50mm, gradually increase the distillation temperature to 95°C, and closel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com