Sodium Secondary Battery

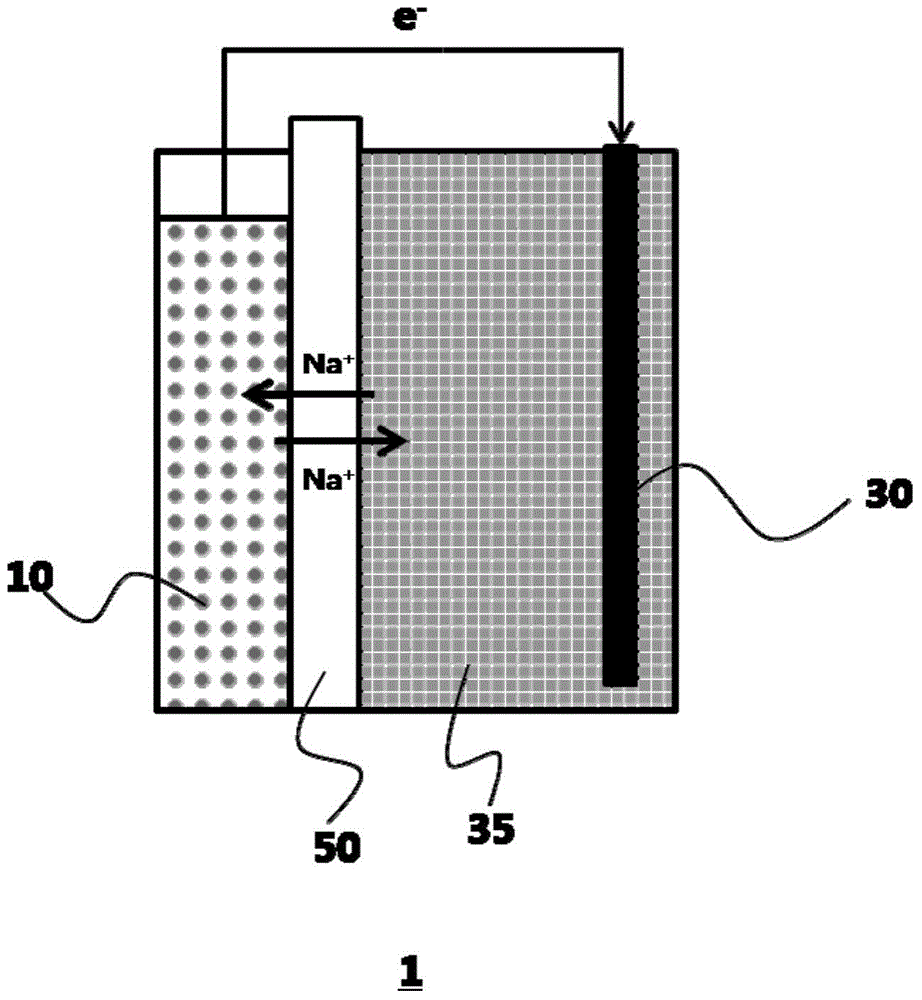

A sodium secondary battery and sodium ion conduction technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of low competitiveness and low power, and achieve the goals of improving battery life, preventing deterioration, and improving battery power efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

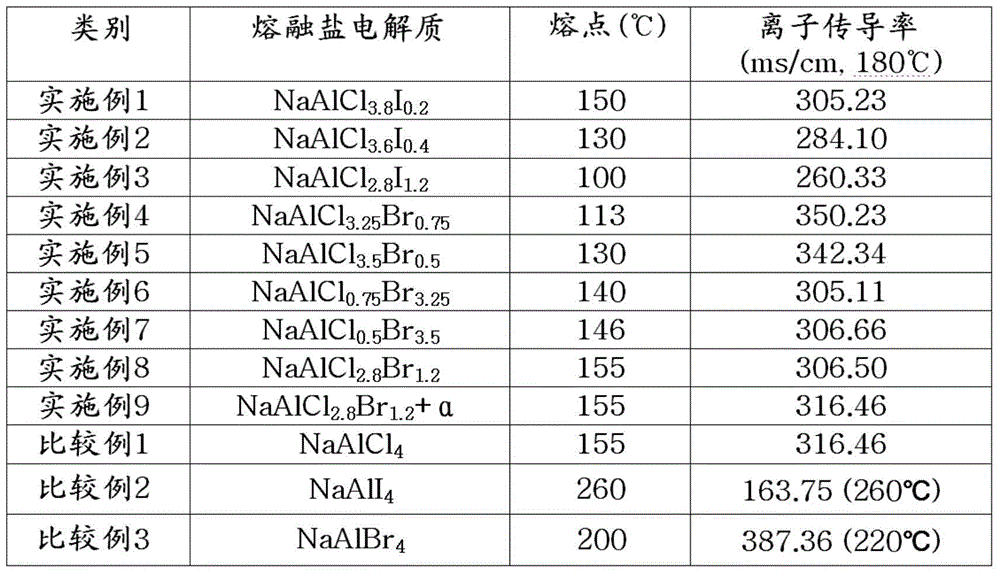

Embodiment 1

[0059] Mix the first salt NaAlCl according to the predetermined ratio 4 with the second salt NaAlI 4 , and confirm the melting point. Confirmed by NaAlCl 4 : NaAlI 4 The melting point of the electrolyte manufactured by mixing the 9.5:0.5 molar ratio is 150 ° C, and the melting point is higher than that of NaAlCl 4 Single salt (comparative example 1) or NaAlI 4 The single salt (comparative example 2) is low, and its ion conductivity is suitable for battery implementation.

Embodiment 2

[0061] Mix the first salt NaAlCl according to the predetermined ratio 4 with the second salt NaAlI 4 , and confirm the melting point. Confirmed by NaAlCl 4 : NaAlI 4 The melting point of the electrolyte manufactured by mixing in a 9:1 molar ratio is 130°C, which is higher than that of NaAlCl 4 Single salt (comparative example 1) or NaAlI 4 The single salt (comparative example 2) is low, and its ion conductivity is suitable for battery implementation.

Embodiment 3

[0063] Mix the first salt NaAlCl according to the predetermined ratio 4 with the second salt NaAlI 4 , and confirm the melting point. Confirmed by NaAlCl 4 : NaAlI 4 The melting point of the electrolyte manufactured by mixing in a 7:3 molar ratio is 100°C, which is higher than that of NaAlCl 4 Single salt (comparative example 1) or NaAlI 4 The single salt (comparative example 2) is low, and its ion conductivity is suitable for battery implementation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com