Hole drilling apparatus and method for cutting machine

The technology of a drilling device and drilling method, which is applied in the direction of metal processing, etc., can solve the problems of damage to air permeability, cutting damage, damage to softness, etc., and achieve the effects of preventing air leakage, preventing increase in resistance, and avoiding reduction in cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

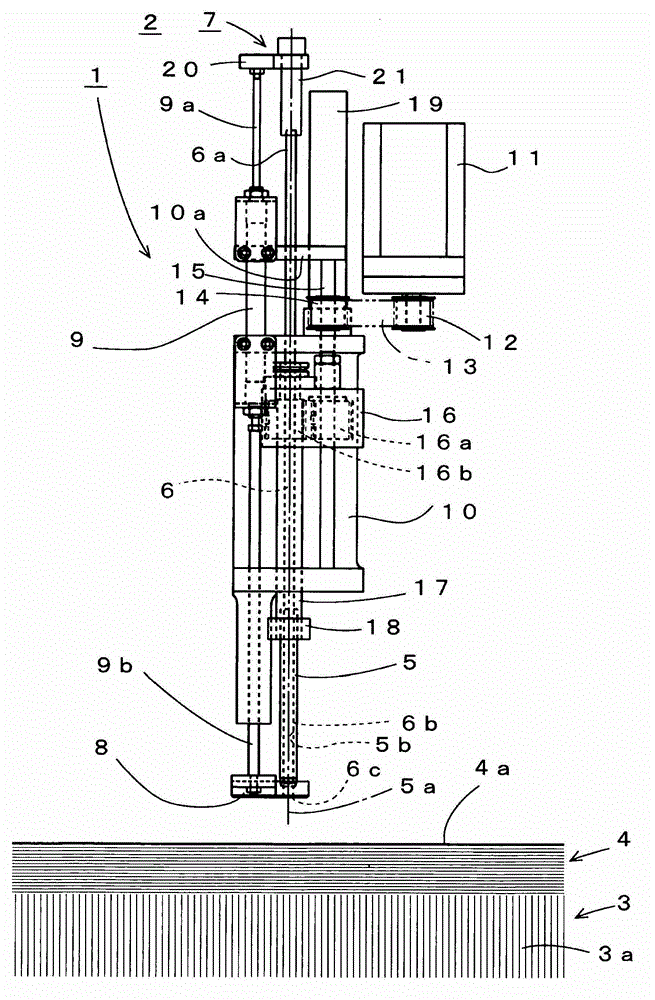

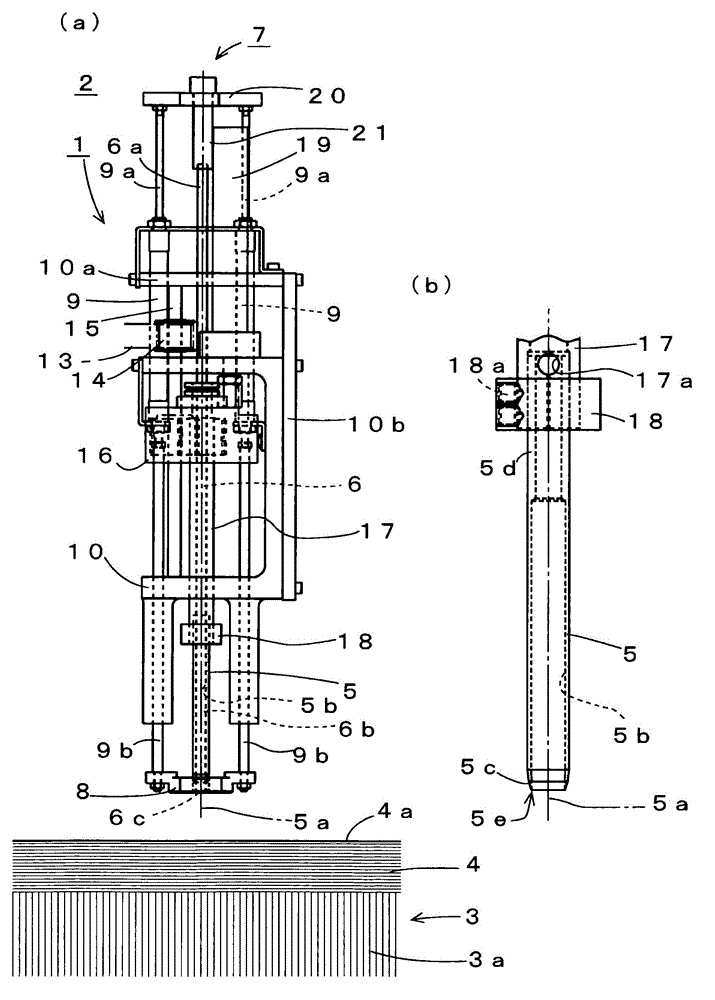

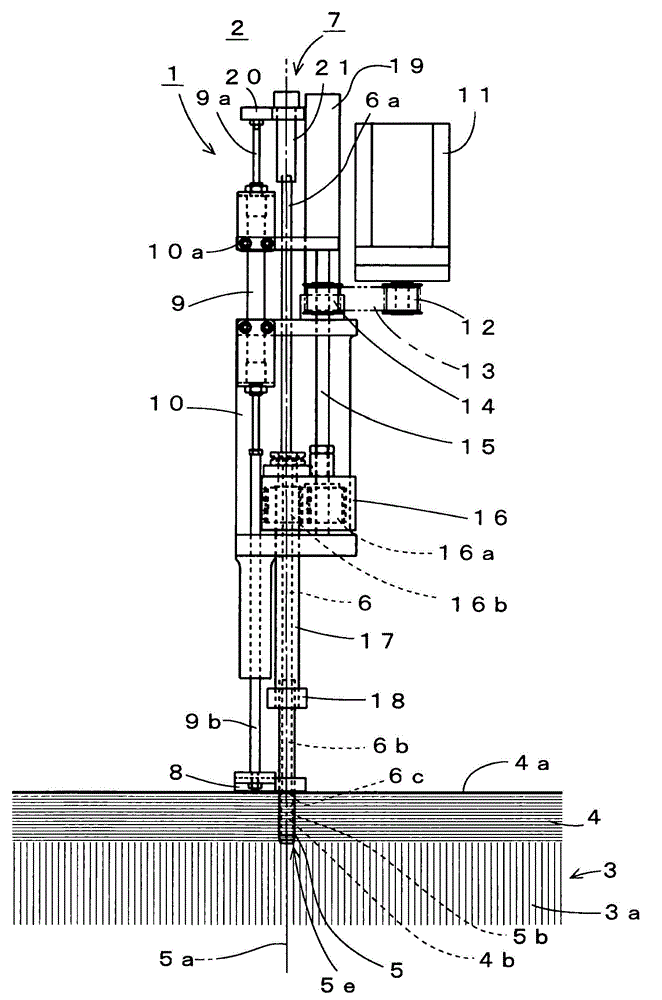

[0039] figure 1 and figure 2 The drilling device 1 shown in (a) is equipped with a cutting head that moves planarly along the surface of the cutting table 3 of the cutting machine 2 . Although illustration of the cutting head and the blade is omitted, the blade cuts the sheet materials 4 stacked on the cutting table 3 in accordance with preset cutting data. In order to hold the sheet material 4 in advance during cutting by the blade, the surface of the cutting table 3 is constituted by bristle brushes 3 a or the like. The bristle brush 3a has the flexibility to escape from the edge of the blade if the edge of the blade penetrates while maintaining air permeability for allowing the suction force from below to act. The surfaces of the laminated sheet materials 4 are covered with an air-impermeable film 4a. The drilling device 1 includes a hollow cylindrical rotary drill 5 for drilling.

[0040] figure 2 (b) shows the structure of the rotary drill 5 . The rotary drill 5 r...

Embodiment 2

[0056] Figure 7 , as another embodiment of the present invention, shows a structure in which a removing device 30 is provided near the surface of the sheet material 4 . The removal device 30 is built into a foot plate 31 that is driven up and down by the lower rod 9 b of the drive cylinder 9 . A suction hose 32 is connected to the foot pressure plate 31 . A discharge nozzle 33 is also provided on the foot pressure plate 31 , and compressed air is supplied through a discharge hose 34 . The cuttings 4 b pressed by the lower end 6 c of the pressing pin 6 in the foot press plate 31 so as to stay on the surface of the sheet material 4 can be moved to the suction hose 32 by blowing compressed air from the blowing nozzle 33 . , to remove by suction. If the suction force is large, the discharge nozzle 33 may not be provided. In addition, instead of using the structure on the suction side such as the suction hose 32, an outlet hole may be provided on the foot press plate 31, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com