Accuracy design method based on frequency domain error distribution for ultraprecise fly cutting machine tool

An error allocation and ultra-precise technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve the problems of not considering the frequency domain error requirements of the workpiece, poor processing quality and reliability of the workpiece, and poor adaptability, etc., to achieve design Excellent flexibility and adaptability, strong reliability and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

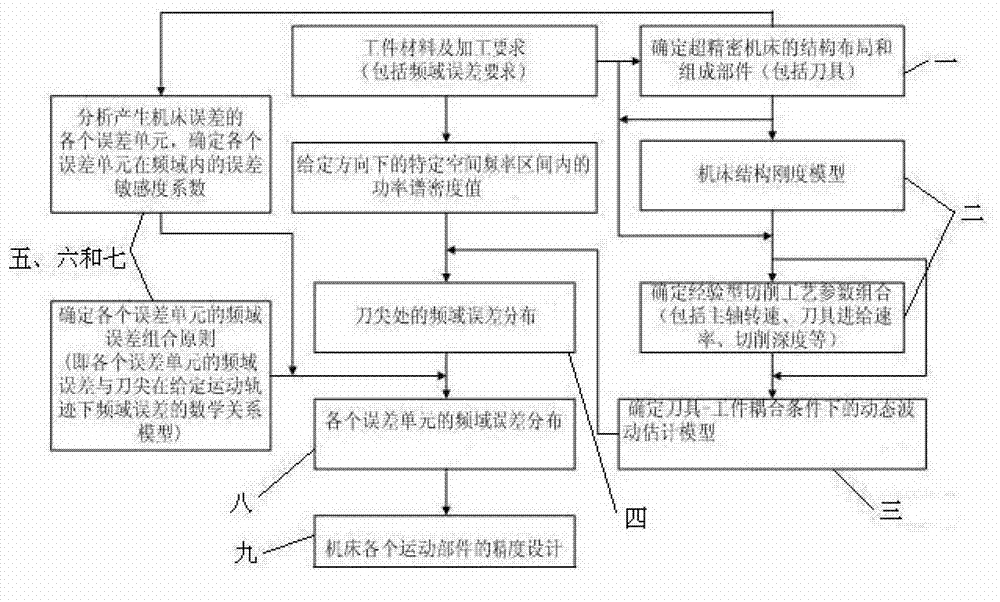

[0017] Specific implementation mode one: combine figure 1 Describe this embodiment, the specific steps of a kind of precision design method of ultra-precision flying cutting machine tool based on frequency domain error distribution of this embodiment are:

[0018] Step 1. According to the processing requirements of the optical workpiece, that is, the given evaluation of the error of the optical element to be processed in a certain spatial frequency interval, that is, the power spectral density of the frequency domain error, expressed in PSD, to determine the structural layout and components of the ultra-precision machine tool ;

[0019] Step 2. Determine the cutting process parameters according to the characteristics of the tool, the structural stiffness model of the machine tool and the material properties of the workpiece; the machine tool stiffness model is obtained by the finite element method, and the cutting process parameters refer to the spindle speed, the tool feed ra...

Embodiment

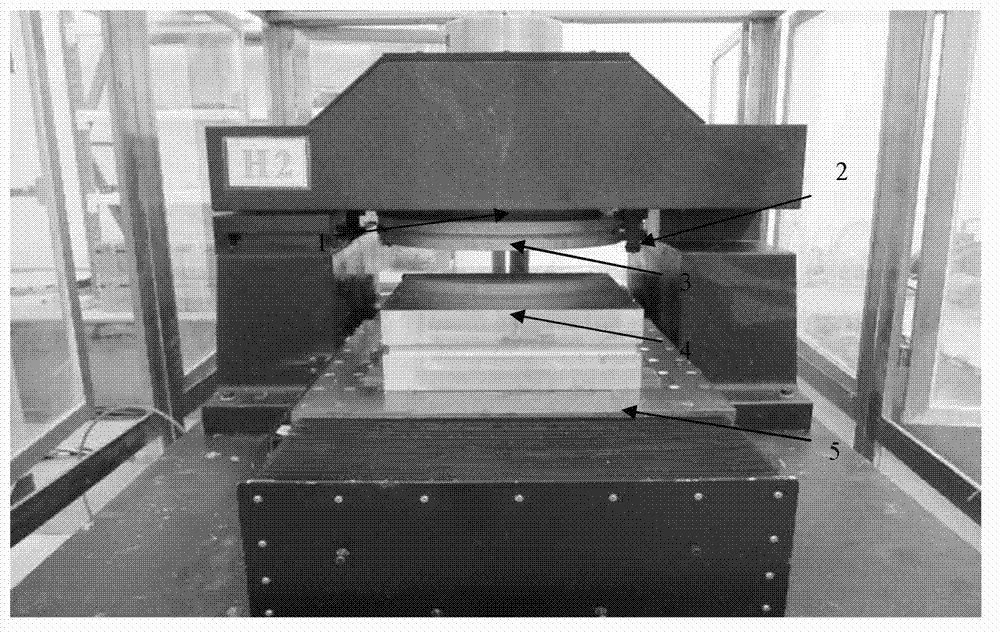

[0035] In order to further illustrate the present invention, in conjunction with figure 1 and figure 2 To illustrate this embodiment, the KDP crystal element used in the inertial confinement laser nuclear fusion system not only has a very high error requirement in the space domain, but also has a high error requirement in the frequency domain. The intermediate frequency error of the surface shape of the KDP crystal element, its main influence on the beam quality is to cause the decrease of the center brightness and make it broaden, which is an important reason for nonlinear self-concentration, and has a great influence on the safe operation of the laser system. harm. The spatial frequency interval corresponding to the intermediate frequency error is 0.03mm -1 -1 , that is, the spatial domain period range is 0.12mm2 mm. In this embodiment, the present invention is described by taking the data as an example of the target frequency domain error requirement of the workpiece su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com