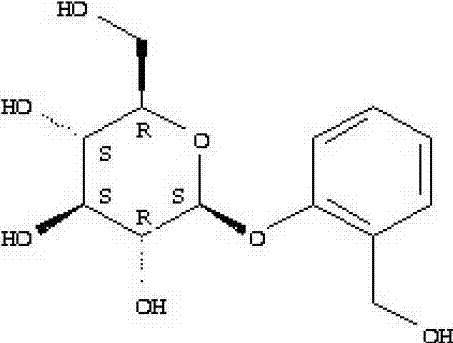

Preparation process of salicin comparison product

A preparation process, a technology for crude salicin, applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

[0021] The preparation process of the salicin reference substance provided by the embodiments of the present invention comprises the following steps:

[0022] (1) Extraction of salicin from poplar flowers: Take 4kg of poplar flowers, cut them into pieces, add 15 times the amount of water to decoct and extract twice, each time for 1.5h, combine the two liquids, filter, let the filtrate stand overnight, and take the upper layer to clarify the extract A , (about 95L), spare;

[0023] (2) Preliminary separation of salicin by macroporous resin, including the following steps (21) and (22):

[0024] (21) Pretreatment of macroporous resin: take macroporous resin D-1015kg, add acetone 8000-10000ml, stir, soak for 12 hours, put into chromatography column, drain acetone, rinse with distill...

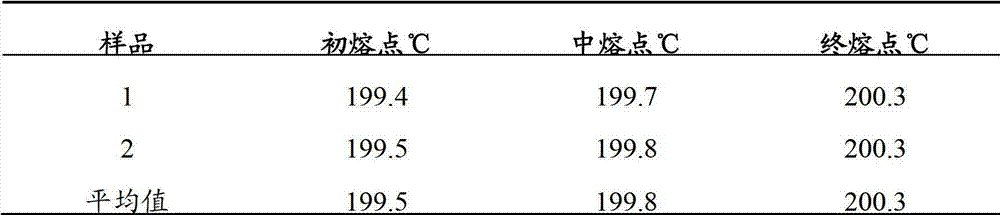

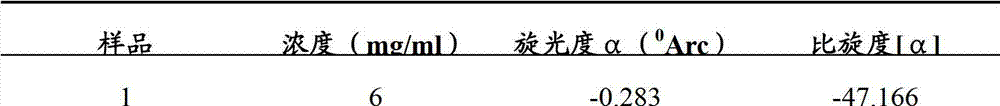

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com