Yellow reactive dye wide in applicable range and preparation method thereof

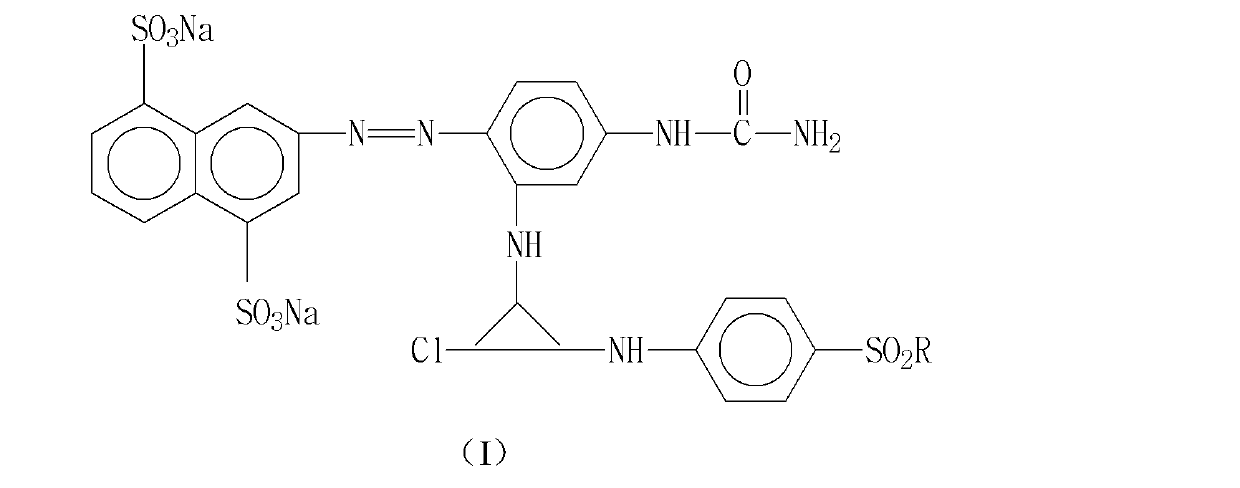

A reactive dye and yellow technology, applied in the field of yellow reactive dye and its preparation, can solve the problems of increasing dye coloring rate, color fixing rate and dye wastewater requirements, not enough bright color, poor fastness, etc. To achieve the effect of bright color, easy operation and excellent fastness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

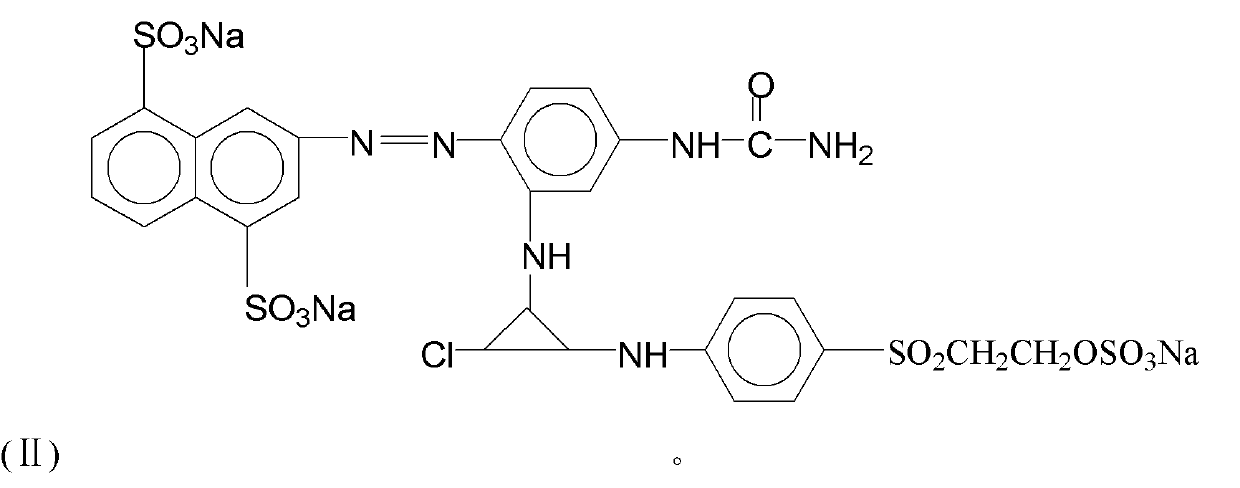

[0046] A kind of yellow reactive dye, this reactive dye has the structural formula of formula (II):

[0047]

[0048]

[0049] The preparation method of this reactive dye, comprises the steps:

[0050] a, diazotization: add 180 parts of bottom water to the diazotization reaction tank, add 30.3 parts of amino acid C, add 100 parts of crushed ice after stirring evenly, add 15 parts of 30wt% hydrochloric acid, and then quickly add 35 parts of 20wt% hydrochloric acid Sodium nitrate aqueous solution, keep stirring for 2 hours at 0-5°C, after the reaction is completed, remove excess nitrous acid with sulfamic acid to obtain diazonium solution for coupling;

[0051] b. Coupling: Add 80 parts of bottom water to the coupling tank, then add 18.7 parts of m-semicarbazide, add 15wt%Na 2 CO 3 Adjust the pH of the solution to 7, disperse evenly, then add the diazonium solution prepared in step a in 1 hour, and use 15wt% Na 2 CO 3 The pH of the solution is maintained at 6.5-7, the ...

Embodiment 2

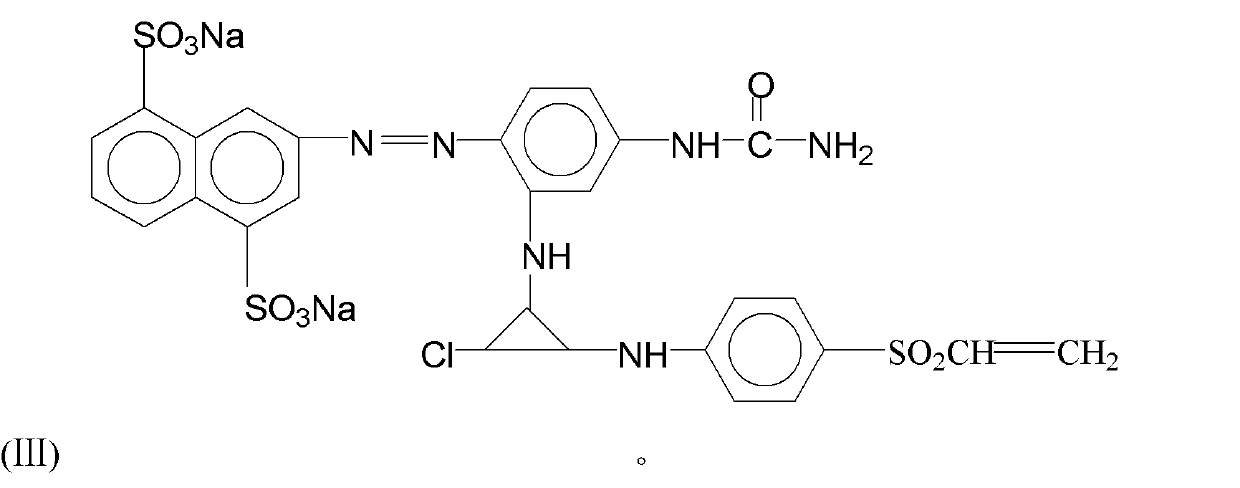

[0056] A yellow reactive dye, the reactive dye has the structural formula of formula (III):

[0057]

[0058] a, diazotization: add 180 parts of bottom water to the diazotization reaction tank, add 30.3 parts of amino acid C, add 100 parts of crushed ice after stirring evenly, add 15 parts of 30wt% hydrochloric acid, and then quickly add 35 parts of 20wt% hydrochloric acid Sodium nitrate aqueous solution, keep stirring for 2 hours at 0-5°C, after the reaction is completed, remove excess nitrous acid with sulfamic acid to obtain diazonium solution for coupling;

[0059] b. Coupling: Add 80 parts of bottom water to the coupling tank, then add 18.7 parts of m-semicarbazide, add 15wt%Na 2 CO 3 Adjust the pH of the solution to 7, disperse evenly, then add the diazonium solution prepared in step a in 1 hour, and use 15wt% Na 2 CO 3 The pH of the solution is maintained at 6.5-7, the temperature is 10°C-15°C, and after the addition is completed, it is stirred under the above con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com