Deep plasma nitriding process of wind gear ring

A technology of ion nitriding and ring gear, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of high energy consumption, long cycle, large deformation, etc., achieve fast speed and small deformation of workpiece , The effect of saving manufacturing cost and construction period

Inactive Publication Date: 2013-01-09

SHANGHAI LONGQIAN HEAT TREATMENT

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the long period, high energy consumption and relatively large deformation of the conventional gas nitriding process for the wind power ring gear, and it is difficult to achieve heat treatment distortion, high hardness, and deep penetration by using the conventional ion nitriding process. To provide a deep ion nitriding process for wind power ring gears due to defects such as the thickness of the nitrogen layer and the higher level of nitriding structure, the process cycle is short, low energy consumption, high quality control accuracy, and the surface hardness of the ring gear after nitriding , the wear resistance and fatigue strength are improved, and the distortion is small, the gear precision is high, and it can be directly assembled and used without grinding, which fully meets the quality and technical requirements of the wind power ring gear

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

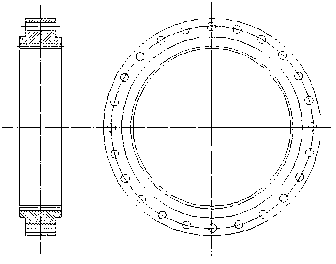

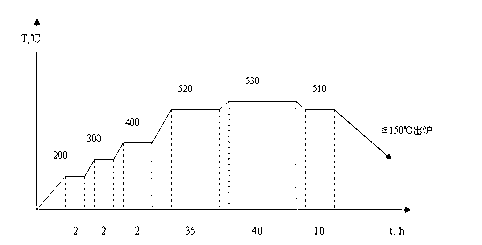

The invention relates to a deep plasma nitriding process of a wind gear ring, characterized by slowly steppedly heating up a wind gear ring workpiece to 520 DEG C with the furnace after charging, preserving the heat for a certain time, letting ammonia in a nitriding furnace, continuing to heat up to 530 DEG C and preserving the heat for a certain time, then cooling to 510 DEG C and preserving the heat for a certain time, after finishing nitriding, slowly cooling to 150 DEG C and discharging the wind gear ring workpiece, preferably a 42CrMo wind gear ring; further, mechanical masking is used for carrying out protection treatment on the workpiece. Compared with the prior art, the process has the advantages of short period of the process, low energy consumption, high precision of quality control, and raised surface hardness, raised wear resistance and raised fatigue strength after gear ring nitriding, low distortion, and high gear precision, can be directly assembled without grinding, and can completely reach the quality technical requirements of wind gear rings.

Description

technical field [0001] The invention relates to a heat treatment process, in particular to a deep ion nitriding process of a wind power ring gear. Background technique The inner ring gear in the wind power of the new clean energy industry requires the nitriding process because it is difficult to meet the deformation requirements with other heat treatment methods. For the high quality requirements of the wind power ring gear after nitriding: the surface hardness is greater than 600HV, the depth of the nitriding layer is 0.7-0.9mm and the higher structure requirements of the nitriding layer, especially to ensure the accuracy and performance requirements of the wind power ring gear, the design It is stipulated that regrinding is not allowed after nitriding, so the distortion of the ring gear after nitriding is required to be controlled within 0.03mm. Due to the requirement of deep permeation layer of the inner ring gear, considering that the conventional gas nitriding proce...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C8/36

Inventor 吕习军

Owner SHANGHAI LONGQIAN HEAT TREATMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com