Pneumatic water turbine

A technology of water turbines and gas turbines, which is applied to engine components, impact engines, machines/engines, etc., can solve the problems of exhaust gas loss, gas leakage loss, high exhaust gas pressure discharge, etc., achieve broad application prospects, improve energy utilization, and overall The effect of high machine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

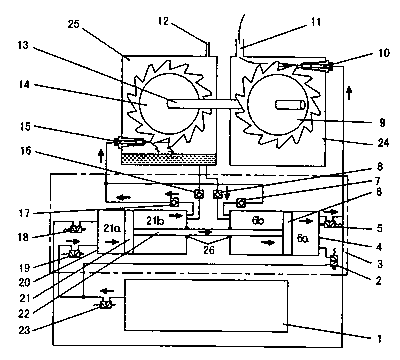

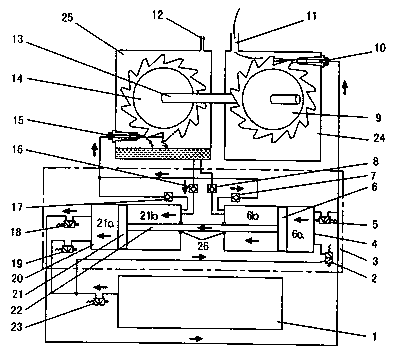

[0019] figure 1 , 2 The working principle diagram of the pneumatic water turbine is given. In the figure, the pneumatic hydraulic turbine includes a high pressure gas tank 1, an energy converter 3, a gas turbine 24 and a water turbine 25, the gas turbine 24 is provided with a gas turbine rotor 9, the water turbine 25 is provided with a water turbine rotor 14, and the water tank is arranged at the lower part of the casing of the water turbine 25 , the gas turbine rotor 9 and the water turbine rotor 14 are arranged on the same output shaft 13 . The energy converter 3 adopts two gas-liquid working cylinders, one gas-liquid working cylinder adopts the first piston 6 to divide the first closed cylinder 4 into the first air chamber 6a and the first water chamber 6b, and the other gas-liquid working cylinder adopts the first piston 6 Two pistons 21 divide the second closed cylinder 20 into a second air chamber 21a and a second water chamber 21b, and a connecting shaft 22 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com