Anti-static plastic tube

A plastic tube, anti-static technology, applied in the field of plastic products, can solve problems such as damage to production equipment, explosion, threat to personnel safety, etc., to achieve the effect of improving performance and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

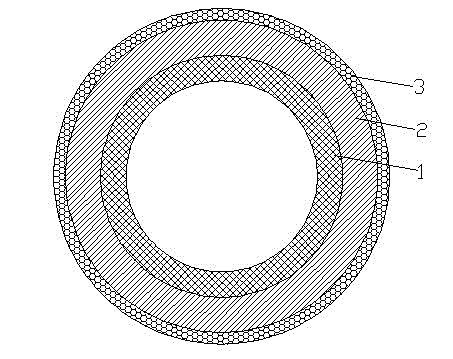

[0012] Described in the present invention is a kind of antistatic plastic pipe, see figure 1 , including an antistatic matrix 1 of the inner layer of the pipeline and a heat-insulated pipe 2 of the outer layer of the pipeline, the surface of the heat-insulated pipe 1 is provided with a layer of anti-aging agent 3, and the antistatic matrix 1 is made of adding ethoxylated lauryl The modified polyamide-6 plastic pipe of the amine antistatic agent is composed of the polyamide-6 plastic pipe, the heat insulation pipe 2 is composed of a polysulfone plastic pipe, and the antiaging agent 3 is 3,5-di-tert-butyl-4-hydroxybenzene cetyl formate film layer.

[0013] Further, the modified polyamide-6 plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com