Detection method and test device for impact damage of composite material laminate

A technology of composite material layer and impact damage, which is applied in the direction of impact test, measuring device, machine/structural component test, etc. It can solve the problems of not being able to give the impact energy size, long time, and long time, and achieve strong anti-interference ability , good robustness, good recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings.

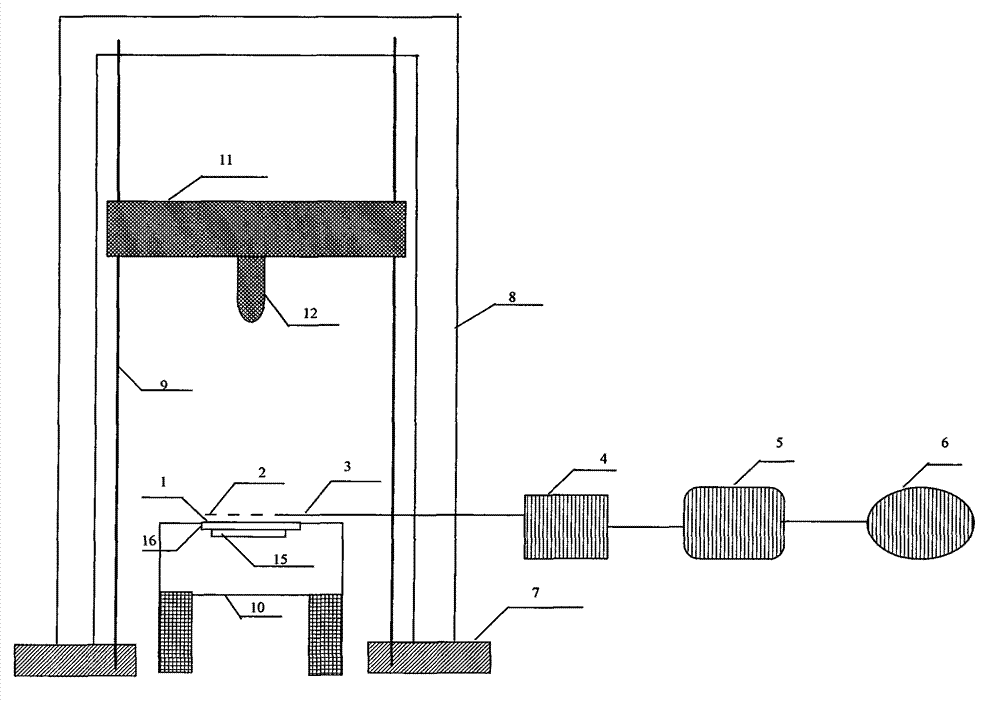

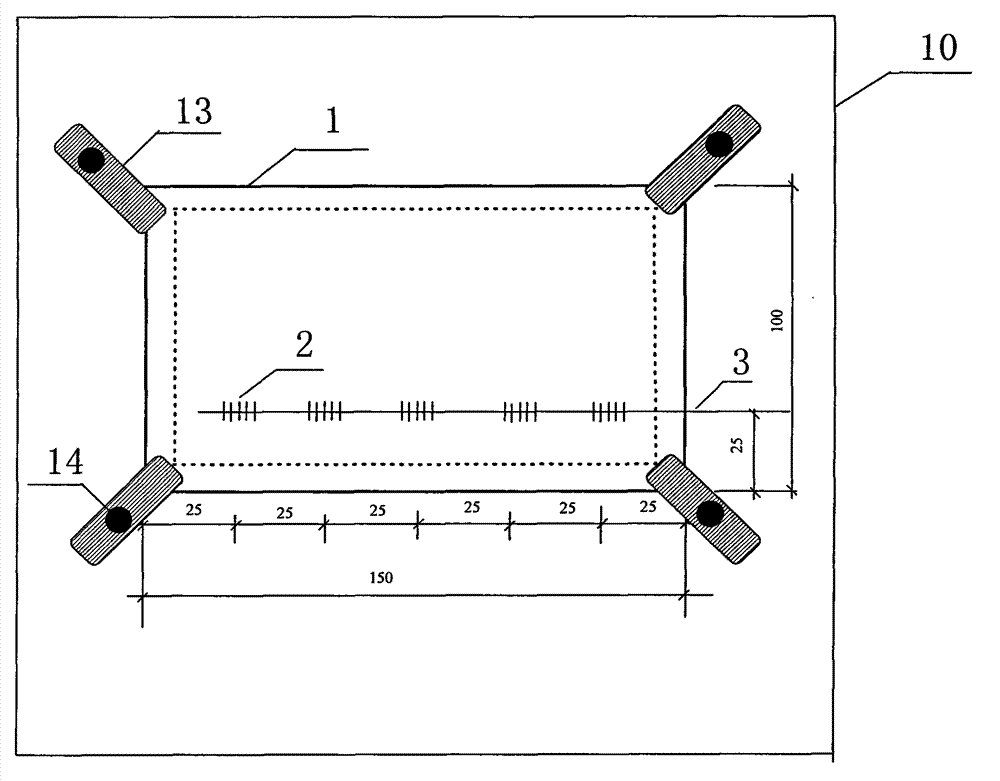

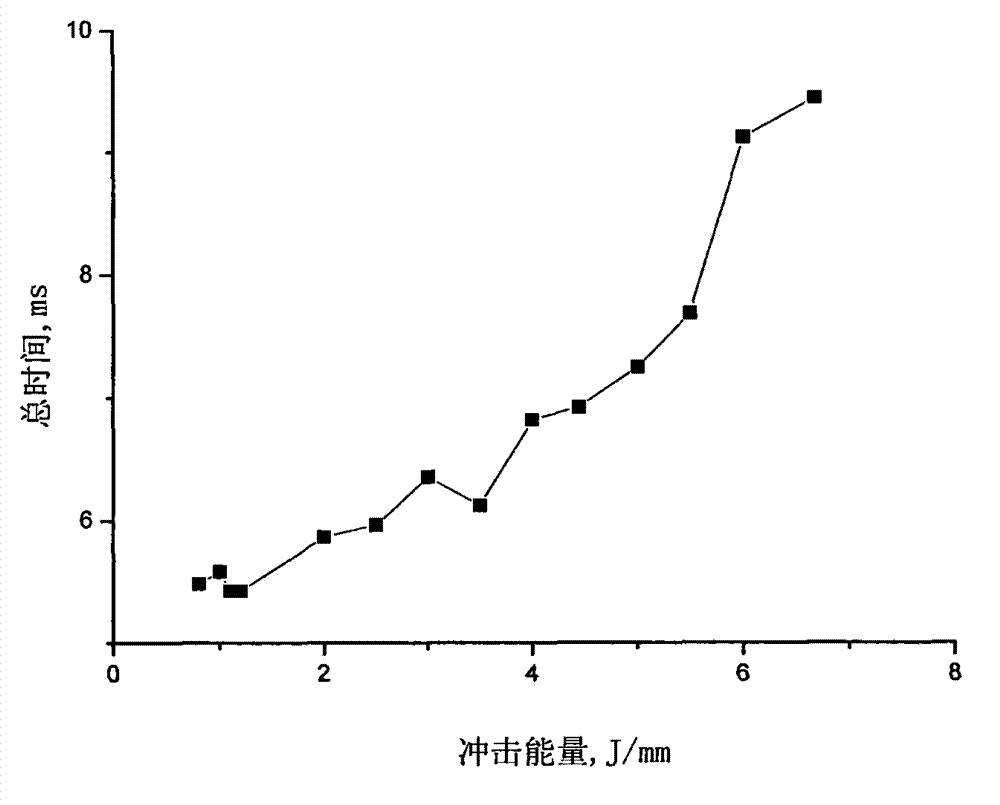

[0032] like figure 1 , figure 2 As shown, the test device includes a composite material laminate 1, a fiber grating strain sensor 2, a transmission fiber 3, a fiber grating demodulation instrument 4, data storage and analysis software 5, a computer 6, and an impact device 7; wherein, the impact device 7 includes a track The fixed bracket 8, the falling track 9, the fixed base 10, the falling mass block 11 and the impact head 12; the size of the composite material laminate 1 is: 150mm long, 100mm wide and 4mm thick. The composite material laminate 1 is made of CCF300 fiber and 5228A resin, and its layup method is [45 / 0 / -45 / 90] 4s. Such a composite material laminate 1 may be the skin material of an aircraft structure.

[0033] The drop rail 9 is installed on the fixed bracket 8 , the fixed base 10 is placed directly under the impact head 12 , the falling mass block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com