Method for manufacturing soft superconducting thin film

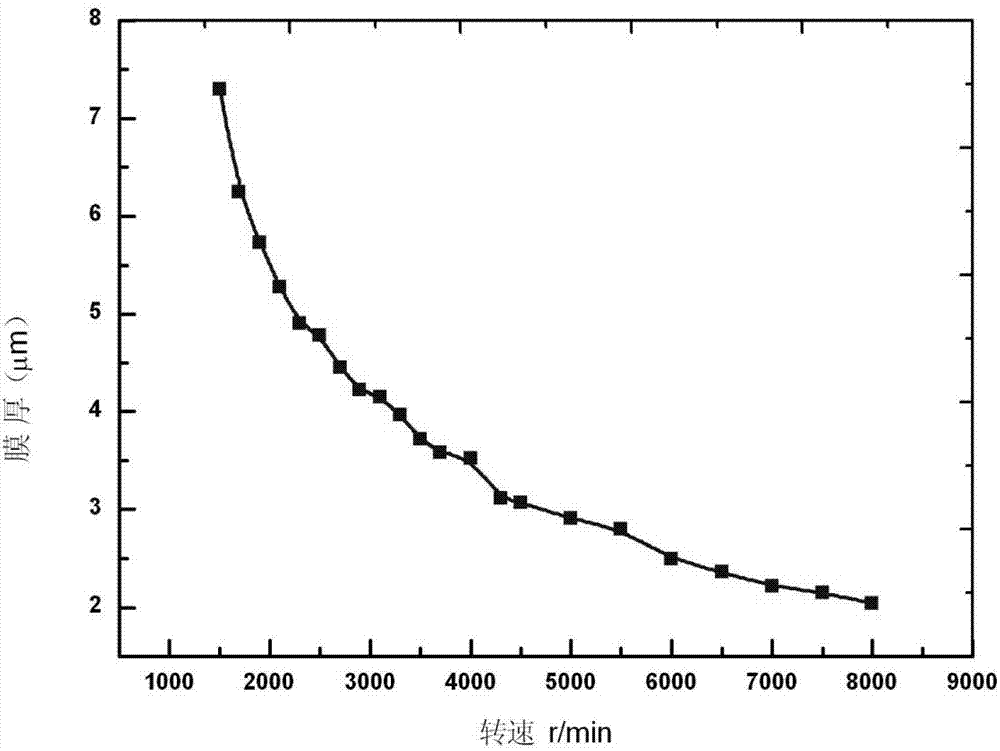

A superconducting thin film, flexible technology, applied in the manufacture/processing of superconductor devices, ion implantation plating, coating, etc., can solve the limited application occasions, limited mixed use of different superconducting materials work occasions, portable silicon technology Compatibility limitations and other issues, to achieve the effect of simple method, expanding application occasions and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

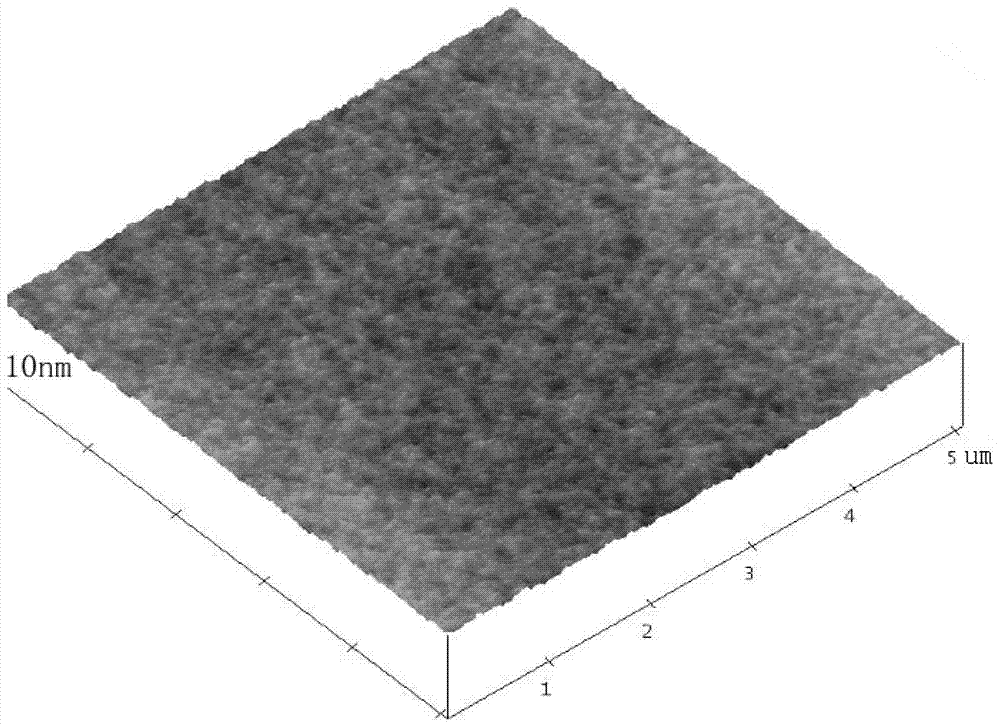

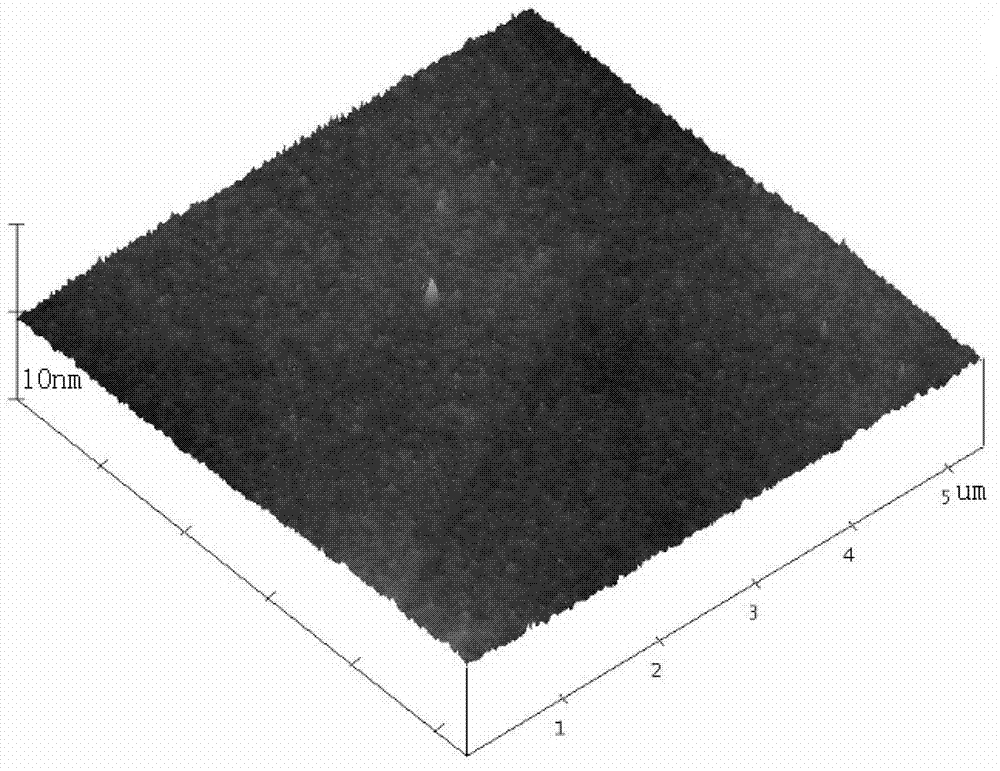

[0021] Polyimide is a ring-chain polymer with an imide ring structure in the molecular main chain, and is widely used in aerospace, electronic appliances, electromechanical, automotive and other industries. Polyimide is one of the organic polymer materials with the best comprehensive performance. It has good insulation performance and flexibility. It can withstand high temperatures above 400°C and extremely low temperatures. It will not be brittle in liquid helium at -269...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com