Preparation method of fat substitute for fermented sausage

A technology of fat substitute and fermented sausage, which is applied in the field of food processing, can solve the problem of lack of sensory characteristics of fat substitute, and achieve the effect of reducing fat content, simple operation steps and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

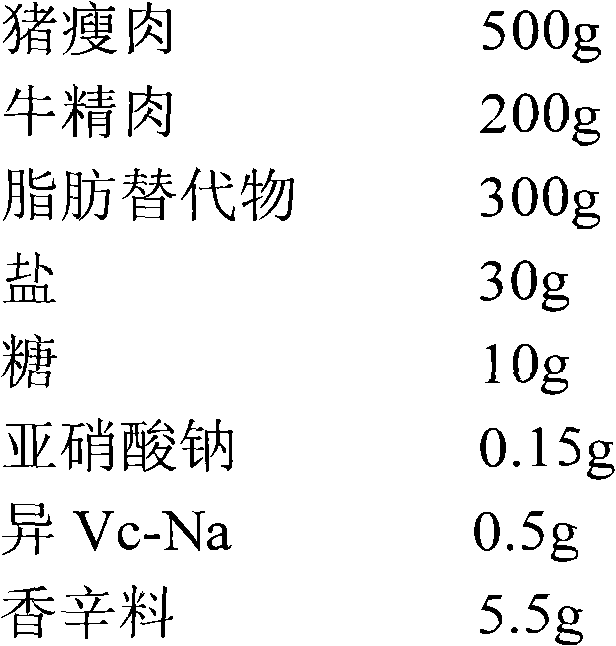

Examples

preparation example Construction

[0025] A method for preparing a fat substitute for fermented sausage,

[0026] The base material is 40-50 parts of sodium alginate, 25-40 parts of calcium salt, and 1.0-2.0 parts of chelating agent;

[0027] The excipients are 20-30 parts of emulsifier, 20-30 parts of lipid substance, and 1000 parts of water;

[0028] The preparation method comprises the following steps:

[0029] (1) mixing sodium alginate, calcium salt, chelating agent and emulsifier, lipid substance, water;

[0030] (2) Perform rapid whipping to generate a uniform sol,

[0031] (3) Pour the sol into the mold and place it for molding, and finally release the mold.

[0032] The calcium salt is preferably calcium carbonate or calcium lactate.

[0033] The chelating agent is preferably phosphate.

[0034] The chelating agent is preferably sodium hexametaphosphate or sodium pyrophosphate.

[0035] The emulsifier is preferably sodium caseinate, xanthan gum or konjac gum.

[0036] The lipid substance is pref...

Embodiment 1

[0043] A recipe for a fat substitute:

[0044] The base material is 50 parts of sodium alginate, 25 parts of calcium carbonate, and 2.0 parts of sodium hexametasulfate;

[0045] The auxiliary materials are 20 parts of sodium caseinate, 30 parts of pig back fat, and 1000 parts of water;

[0046] making process:

[0047] (1) Grind pig back fat with a mixer (18000r / min, 1min), add mixed sodium alginate, calcium salt, phosphate, sodium caseinate powder, add water and stir (18000r / min, 8min) until A uniform viscous sol is formed.

[0048] (2) The stirred sol was quickly poured into the mold, and placed in an environment of 4° C. for 6 hours.

[0049] (3) After the gel is molded, it is demoulded and packaged.

Embodiment 2

[0051] A recipe for a fat substitute:

[0052] The base material is 40 parts of sodium alginate, 40 parts of calcium lactate, and 1.0 part of sodium pyrosulfate;

[0053] The auxiliary materials are 30 parts of xanthan gum, 20 parts of soybean oil, and 1000 parts of water;

[0054] making process:

[0055] (1) Add the weighed soybean oil into the blender, add the mixed sodium alginate, calcium lactate, sodium pyrophosphate, xanthan gum, add water and stir quickly (18000r / min, 8min) until a uniform and viscous mixture is formed. Sol body.

[0056] (2) The stirred sol was quickly poured into the mold, and placed in an environment of 4° C. for 6 hours.

[0057] (3) After the gel is molded, it is demoulded and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com