Process for machining marine gear

A marine gear and processing technology, applied in the field of gear processing, can solve the problems of low hardness, insufficient toughness, and low motion accuracy, and achieve the effects of good toughness, elimination of residual stress, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

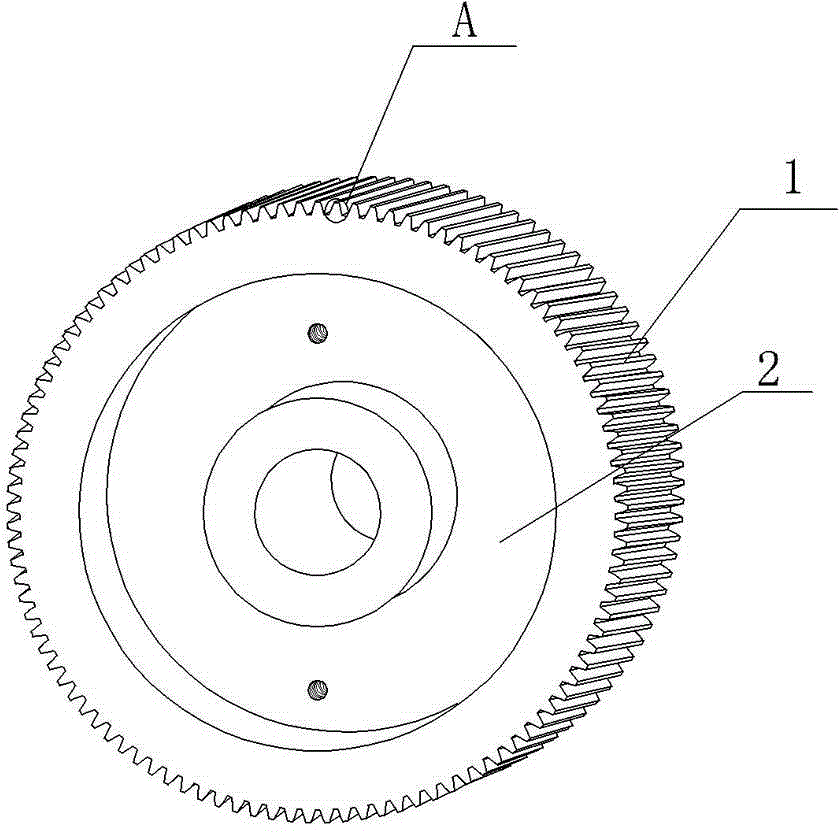

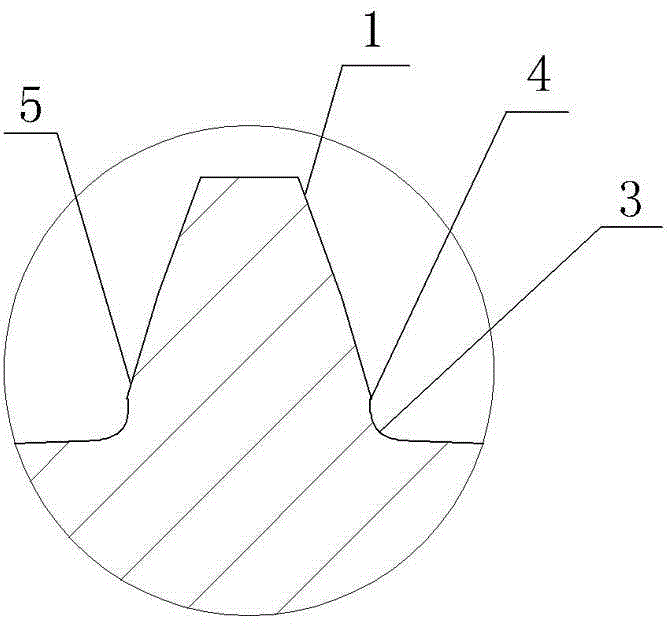

Image

Examples

Embodiment

[0015] A marine gear processing technology. First, 20GrMnTi is used as a raw material for forging. The thickness of the forged workpiece is 5cm. Then, the forged workpiece is heated to 420°C, kept for 5 hours and cooled in the furnace. Then carry out turning processing, drill a hole in the center of the workpiece, hob the outer peripheral surface of the workpiece, and process the spline in the center hole. The approximate shape of the workpiece after machining has been completed, and then carburized, the workpiece is sealed in carbon powder, and the temperature is raised to 700~850°C under a negative pressure of 800 Pa, and the thickness of the carburized layer is guaranteed to be 1.2~1.8mm , keep warm for 2-3 hours, spread for 15 minutes after turning on the furnace, add 20°C normal temperature oil, cool and quench, and keep at 200°C for 2-3 hours after cooling for stress relief treatment. After cooling and quenching, perform secondary high-temperature oil treatment, and plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com